2021 High quality Margarine Plant - Horizontal & Inclined Screw Feeder Model SP-HS2 – Shipu Machinery

2021 High quality Margarine Plant - Horizontal & Inclined Screw Feeder Model SP-HS2 – Shipu Machinery Detail:

Main features

Power supply : 3P AC208-415V 50/60Hz

Charging angle : Standard 45 degree,30~80 degree are also available.

Charging Height : Standard 1.85M,1~5M could be designed and manufactured.

Square hopper, Optional : Stirrer.

Fully stainless steel structure, contact parts SS304;

Other Charging Capacity could be designed and manufactured.

Main Technical Data

|

Model |

MF-HS2-2K |

MF-HS2-3K |

MF-HS2-5K |

MF-HS2-7K |

MF-HS2-8K |

MF-HS2-12K |

|

Charging Capacity |

2m3/h |

3m3/h |

5 m3/h |

7 m3/h |

8 m3/h |

12 m3/h |

|

Diameter of pipe |

Φ102 |

Φ114 |

Φ141 |

Φ159 |

Φ168 |

Φ219 |

|

Total power |

0.95KW |

1.15W |

1.9KW |

2.75KW |

2.75KW |

3.75KW |

|

Total Weight |

140kg |

170kg |

210kg |

240kg |

260kg |

310kg |

|

Hopper Volume |

100L |

200L |

200L |

200L |

200L |

200L |

|

Thickness of Hopper |

1.5mm |

1.5mm |

1.5mm |

1.5mm |

1.5mm |

1.5mm |

|

Thickness of Pipe |

2.0mm |

2.0mm |

2.0mm |

3.0mm |

3.0mm |

3.0mm |

|

Outer dia.of Screw |

Φ88mm |

Φ100mm |

Φ126mm |

Φ141mm |

Φ150mm |

Φ200mm |

|

Pitch |

76mm |

80mm |

100mm |

110mm |

120mm |

180mm |

|

Thickness of Pitch |

2mm |

2mm |

2.5mm |

2.5mm |

2.5mm |

3mm |

|

Dia.of Axis |

Φ32mm |

Φ32mm |

Φ42mm |

Φ48mm |

Φ48mm |

Φ57mm |

|

Thickness of Axis |

3mm |

3mm |

3mm |

4mm |

4mm |

4mm |

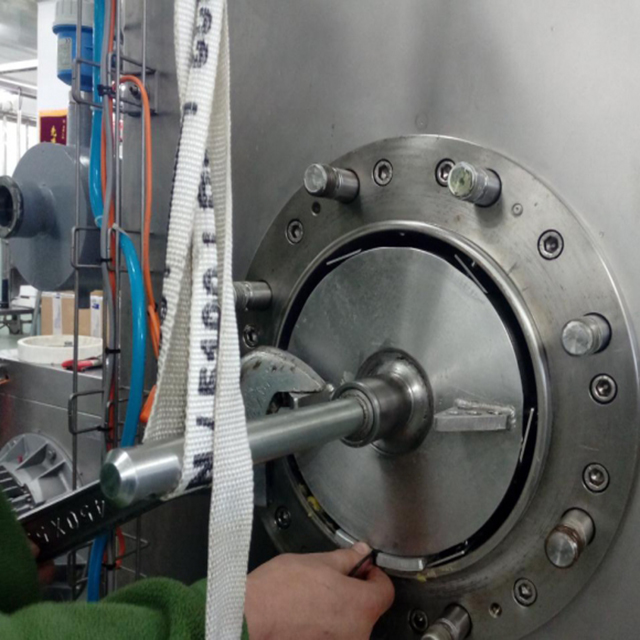

Product detail pictures:

Related Product Guide:

To be the stage of realizing dreams of our employees! To build a happier, more united and more professional team! To reach a mutual benefit of our customers, suppliers, the society and ourselves for 2021 High quality Margarine Plant - Horizontal & Inclined Screw Feeder Model SP-HS2 – Shipu Machinery , The product will supply to all over the world, such as: Nigeria, Jamaica, Malaysia, During in 11 years,We have participated in more than 20 exhibitions,obtains the highest praise from each customer. Our company always aim to provide the customer best products with lowest price. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. Join us, show your beauty. We will always be your first choice. Trust us, you will never lose heart.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.