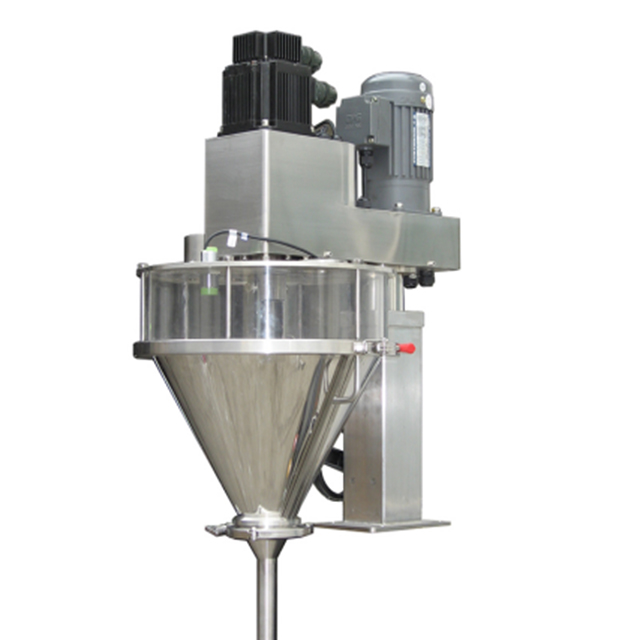

2021 New Style Powder Filling Equipment - Semi-auto Auger filling machine with online weigher Model SPS-W100 – Shipu Machinery

2021 New Style Powder Filling Equipment - Semi-auto Auger filling machine with online weigher Model SPS-W100 – Shipu Machinery Detail:

Main features

Stainless steel structure; Quick disconnecting hopper could be washed easily without tools.

Servo motor drive screw.

Weight feedback and proportion track get rid of the shortage of variable packaged weight for various proportion of different material.

Save the parameter of different filling weight for different materials. To save 10 sets at most

Replacing the auger parts, it is suitable for material from super thin powder to granule.

Main Technical Data

|

Packing Weight |

1kg – 25kg |

|

Packing Accuracy |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

|

Packing Speed |

22 – 8 times per min |

|

Power Supply |

3P AC208 – 415V 50/60Hz |

|

Compressed air |

6kg/cm3 0.1cbm/min |

|

Total Power |

2.37Kw |

|

Total Weight |

350kg |

|

Overall Dimension |

1125×975×2500mm |

|

Hopper Volume |

100L |

Configuration

|

No |

Name |

Model Specification |

PRODUCING AREA, Brand |

|

1 |

Stainless steel | SUS304 |

China |

|

2 |

PLC |

|

Taiwan Fatek |

|

3 |

HMI |

|

Schneider |

|

4 |

Filling Servo motor | TSB13152B-3NTA-1 | Taiwan TECO |

|

5 |

Filling Servo driver | ESDA40C | Taiwan TECO |

|

6 |

Agitator motor | GV-28 0.4kw,1:30 | Taiwan Yu Sin |

|

7 |

Electromagnetic valve |

|

Taiwan SHAKO |

|

8 |

Cylinder | MA32X150-S-CA | Taiwan Airtac |

|

9 |

Air Filter and booster | AFR-2000 | Taiwan Airtac |

|

10 |

Switch | HZ5BGS | Wenzhou Cansen |

|

11 |

Circuit breaker |

|

Schneider |

|

12 |

Emergency switch |

|

Schneider |

|

13 |

EMI Filter | ZYH-EB-10A | Beijing ZYH |

|

14 |

Contactor | CJX2 1210 | Wenzhou CHINT |

|

15 |

Heat relay | NR2-25 | Wenzhou CHINT |

|

16 |

Relay | MY2NJ 24DC |

Japan Omron |

|

17 |

Switching power supply |

|

Changzhou Chenglian |

|

18 |

AD Weighing Module |

|

MAINFILL |

|

19 |

Loadcell | IL-150 | Mettler Toledo |

|

20 |

Photo sensor | BR100-DDT | Korea Autonics |

|

21 |

Level sensor | CR30-15DN | Korea Autonics |

Product detail pictures:

Related Product Guide:

Attaining consumer satisfaction is our company's purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for 2021 New Style Powder Filling Equipment - Semi-auto Auger filling machine with online weigher Model SPS-W100 – Shipu Machinery , The product will supply to all over the world, such as: Bogota, India, venezuela, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.