2021 wholesale price Absorption Tower - Margarine Pilot Plant Model SPX-LAB (Lab scale) – Shipu Machinery

2021 wholesale price Absorption Tower - Margarine Pilot Plant Model SPX-LAB (Lab scale) – Shipu Machinery Detail:

Working Principle

The product is pumped into the lower end of the heat exchanger cylinder. As the product flows through the cylinder, it is continuously agitated and removed from the cylinder wall by the scraping blades. The scraping action results in a surface free from fouling deposits and a uniform, high heat transfer rate.

The media flows in counter current direction in the annular space between the heat transfer cylinder and the insulated jacket. A spiral coil provides a higher heat transfer efficiency for steam and liquid media.

Rotor driving is achieved by an electric motor installed on the upper shaft end. Rotor speed and product flow can be varied to suit the application.

SPX series scraped-surface heat exchangers can be connected in series for in line heating and cooling.

Standard Design

SPX series Scraped-surface heat exchanger utilities a modular design for vertical mounting on a wall or column and includes:

● Compact structure design

● Solid shaft connection (60mm) structure

● Durable blade material and technology

● High precision machining technology

● Solid heat transfer tube material and inner hole processing

● The heat transfer tube can be disassembled and replaced separately

● Gear motor drive – no couplings, belts or sheaves

● Concentric or eccentric shaft mounting

● GMP, 3A and ASME design standard; FDA optional

Working temperature : -30°C~ 200°C

Maximum working pressure

Material side : 3MPa (430psig), optional 6MPa (870psig)

Media side : 1.6 MPa (230psig),optional 4MPa (580 psig)

Technical spec.

| 型号 | 换热面积 | 间隙 | 长度 | 刮板 | 尺寸 | 功率 | 耐压 | 转速 |

| Model | Heat Exchanger Surface Area | Annular Space | Tube Length | Scraper Qty | Dimension | Power | Max. Pressure | Main Shaft Speed |

| Unit | M2 | mm | mm | pc | mm | kw | Mpa | rpm |

| SPX18-220 | 1.24 | 10-40 | 2200 | 16 | 3350*560*1325 | 15 or 18.5 | 3 or 6 | 0-358 |

| SPX18-200 | 1.13 | 10-40 | 2000 | 16 | 3150*560*1325 | 11 or 15 | 3 or 6 | 0-358 |

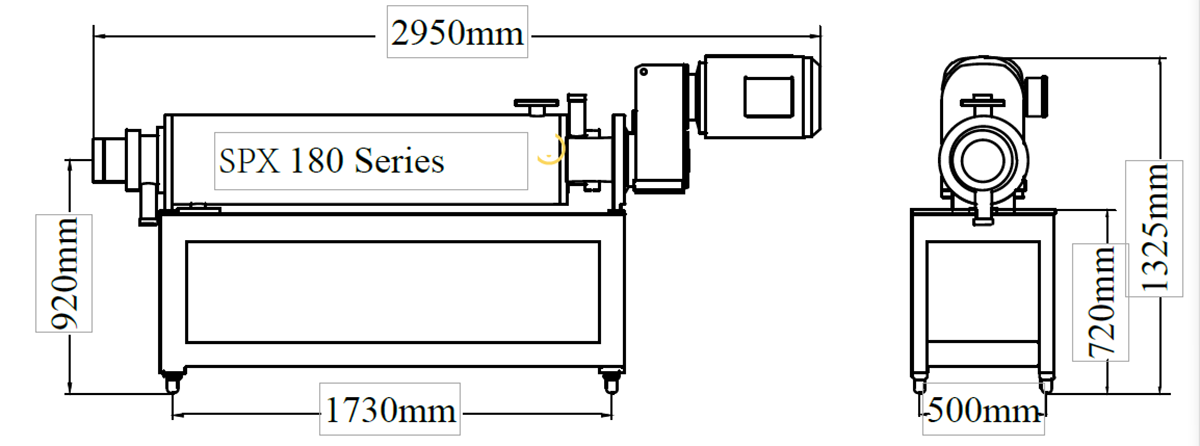

| SPX18-180 | 1 | 10-40 | 1800 | 16 | 2950*560*1325 | 7.5 or 11 | 3 or 6 | 0-340 |

| SPX15-220 | 1.1 | 11-26 | 2200 | 16 | 3350*560*1325 | 15 or 18.5 | 3 or 6 | 0-358 |

| SPX15-200 | 1 | 11-26 | 2000 | 16 | 3150*560*1325 | 11 or 15 | 3 or 6 | 0-358 |

| SPX15-180 | 0.84 | 11-26 | 1800 | 16 | 2950*560*1325 | 7.5 or 11 | 3 or 6 | 0-340 |

| SPX18-160 | 0.7 | 11-26 | 1600 | 12 | 2750*560*1325 | 5.5 or 7.5 | 3 or 6 | 0-340 |

| SPX15-140 | 0.5 | 11-26 | 1400 | 10 | 2550*560*1325 | 5.5 or 7.5 | 3 or 6 | 0-340 |

| SPX15-120 | 0.4 | 11-26 | 1200 | 8 | 2350*560*1325 | 5.5 or 7.5 | 3 or 6 | 0-340 |

| SPX15-100 | 0.3 | 11-26 | 1000 | 8 | 2150*560*1325 | 5.5 | 3 or 6 | 0-340 |

| SPX15-80 | 0.2 | 11-26 | 800 | 4 | 1950*560*1325 | 4 | 3 or 6 | 0-340 |

| SPX-Lab | 0.08 | 7-10 | 400 | 2 | 1280*200*300 | 3 | 3 or 6 | 0-1000 |

| SPT-Max | 4.5 | 50 | 1500 | 48 | 1500*1200*2450 | 15 | 2 | 0-200 |

| 注意:超高压机型可选最高耐压 8MPa,电机功率最大为 22kW. | ||||||||

| Note: High Pressure model can provide pressure environment up to 8MPa(1160PSI)with a motor power of 22KW(30HP) | ||||||||

Cylinder

The inner cylinder diameter are 152 mm and 180mm

Material

The heating surface is normally made of stainless steel, (SUS 316L), honed to a very high finish on the inner surface. For special applications different types of chrome coatings are available for the heating surface. The scraping blades are available in stainless steel and different types of plastic materials including a metal detectable type. The blade material and configuration is selected based on the application. Gaskets and O-rings are made of Viton, nitrile or Teflon. Suitable material will be selected for each application. Single seals, flushed (aseptic) seals are available, with material selection depending on the application

Optional equipment

● Drive motors of different types and different power configurations, also in explosion – proof design

● The standard heat transfer tube material is carbon steel chrome-plated,316L stainless steel , 2205 duplex stainless steel , pure nickel are optional

● Optional Shaft diameters(mm):160, 150, 140, 130, 120, 110, 100

● Optional the products flow from the center of the shaft

● Optional high torque SUS630 stainless steel transmission spline shaft

● Optional High Pressure mechanical seal up to 8MPa (1160psi)

● Optional Water tempered shaft

● The standard type is horizontal installation, and vertical installation is optional

● Optional Eccentric shaft

Machine Drawing

Product detail pictures:

Related Product Guide:

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for 2021 wholesale price Absorption Tower - Margarine Pilot Plant Model SPX-LAB (Lab scale) – Shipu Machinery , The product will supply to all over the world, such as: Guyana, Peru, Brunei, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We've been able to also provide you with no cost samples to meet your needs. Best efforts are going to be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you'll be able to come to our factory to find out it. We'll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we'll share the top trading practical experience with all our merchants.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.