Completed Milk Powder Can Filling & Seaming Line China Manufacturer

Completed Milk Powder Can Filling & Seaming Line China Manufacturer Detail:

Vidoe

Automatic Milk Powder Canning Line

Our Advantage in Dairy Industry

Hebei Shipu is committed to providing high quality one-stop packaging service for dairy industry customers, including milk powder canning line, bag line and 25 kg package line, and can provide customers with relevant industry consulting and technical support. During the past 18 years, we have built long term cooperation with world outstanding enterprises, like Fonterra, Nestle, Yili, Mengniu and etc.

Dairy Industry Introduction

In the dairy industry, the most popular packaging in the world is generally divided into two categories, namely canned packaging (tin can packaging and environment friendly paper can packaging) and bag packaging. Can packaging is more preferred by the end consumers because of its better sealing and longer shelf life.

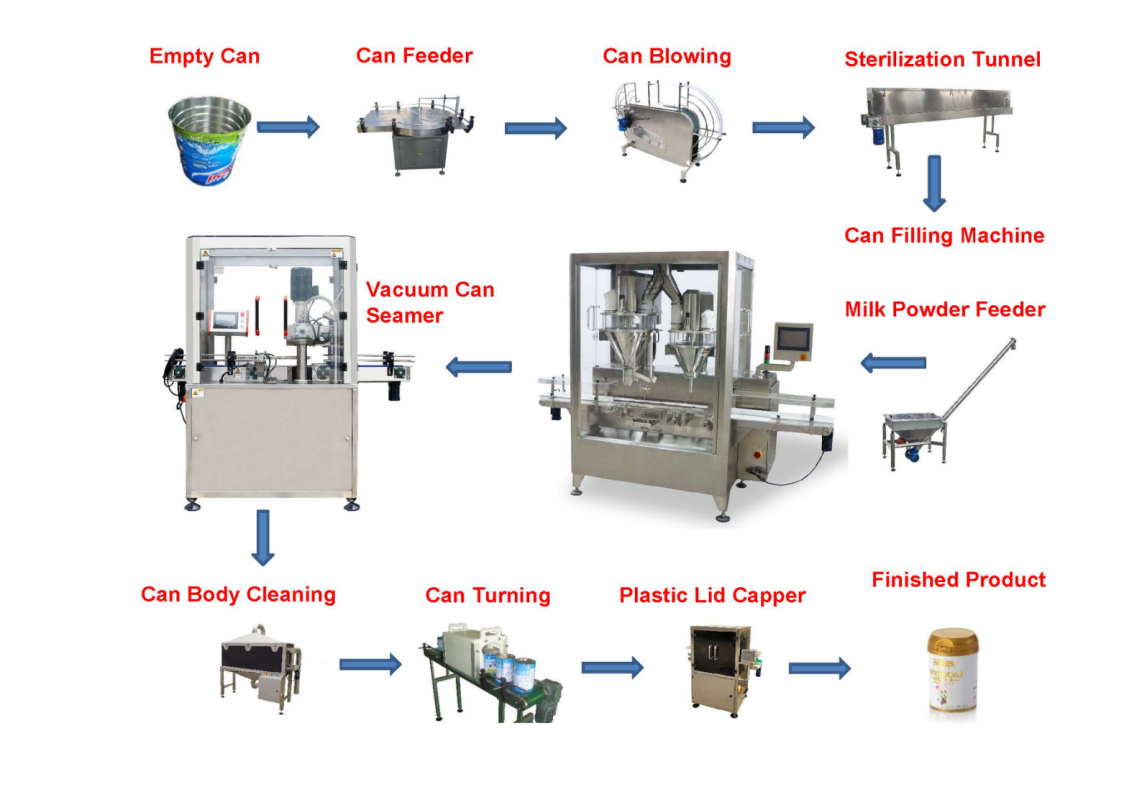

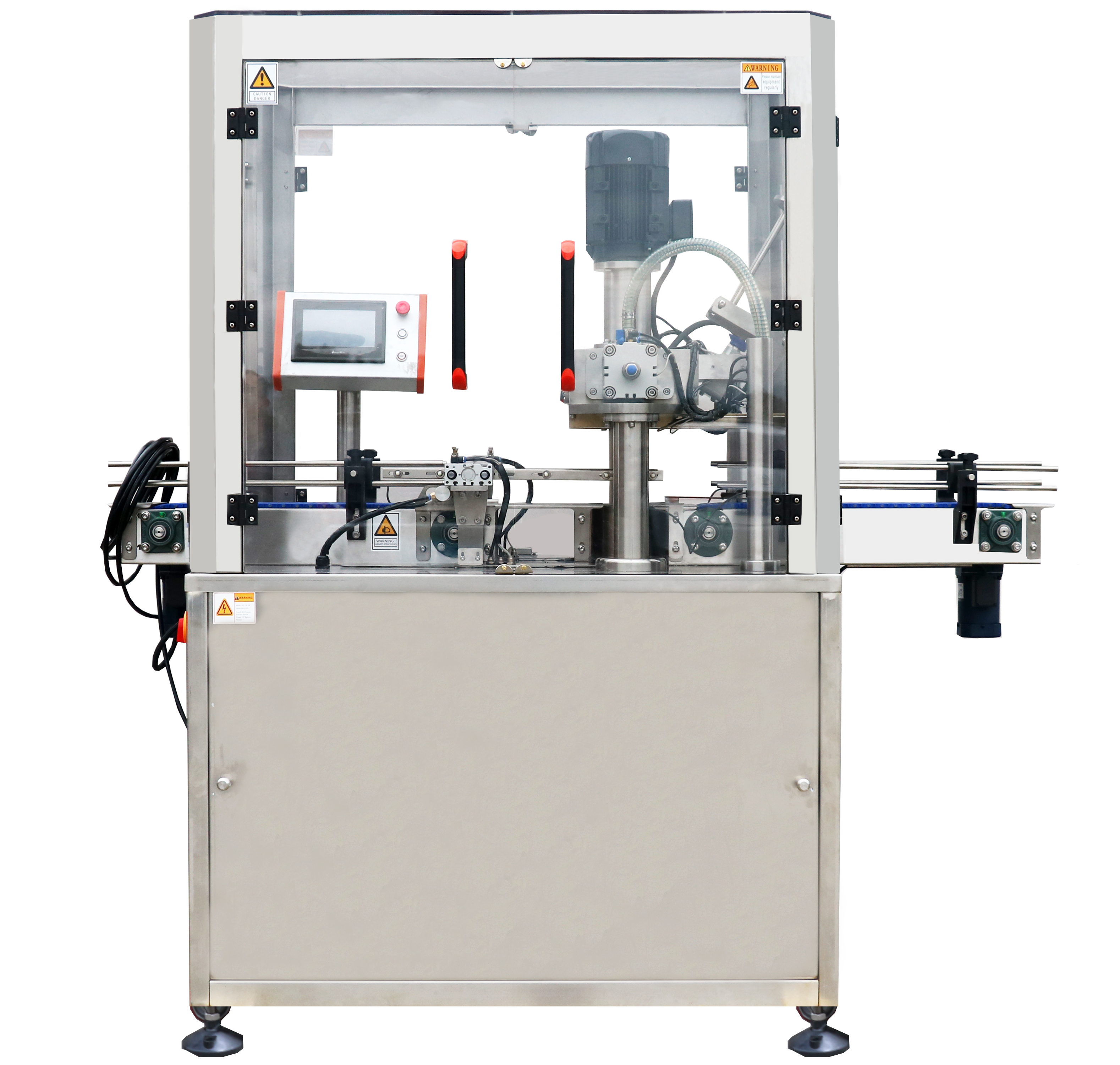

The completed milk powder canning line generally includes de-palletizer, can unscrambling machine, can degaussing machine, can sterilization tunnel, double filler powder filling machine, vacuum seamer, can body cleaning machine, laser printer, plastic lid capping machine, palletizer and etc., which can realize automatic packaging process from the milk powder empty cans to the finished product.

Sktech map

Through the processing technology of the vacuum and nitrogen flushing, the residual oxygen can be controlled within 2%, so as to ensure the shelf life of the product to be 2-3 years. At the same time, the tinplate can packaging also has the characteristics of pressure and moisture resistance, to be suitable for long-distance transportation and long-term storage.

The packaging specifications of canned milk powder can be divided into 400 grams, 900 grams of conventional packaging and 1800 grams and 2500 grams of family promotion packaging. Milk powder manufacturers can change the production line mold to pack different specifications of product.

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the power by quality". Our enterprise has strived to establish a remarkably efficient and stable team team and explored an effective excellent control system for Completed Milk Powder Can Filling & Seaming Line China Manufacturer , The product will supply to all over the world, such as: Uruguay, Latvia, Muscat, During the 10 years of operating, our company always try our best to bring consumption satisfaction for user, built a brand name for ourselves and a solid position in the international market with major partners come from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. Last but not least, price of our products are very suitable and have fairly high competition with other companies.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.