Automatic Potato Chips Packaging Machine SPGP-5000D/5000B/7300B/1100

Automatic Potato Chips Packaging Machine SPGP-5000D/5000B/7300B/1100 Detail:

Application

Cornflakes packaging, candy packaging, puffed food packaging, chips packaging, nut packaging, seed packaging, rice packaging, bean packaging baby food packaging and etc. Especially suitable for easily broken material.

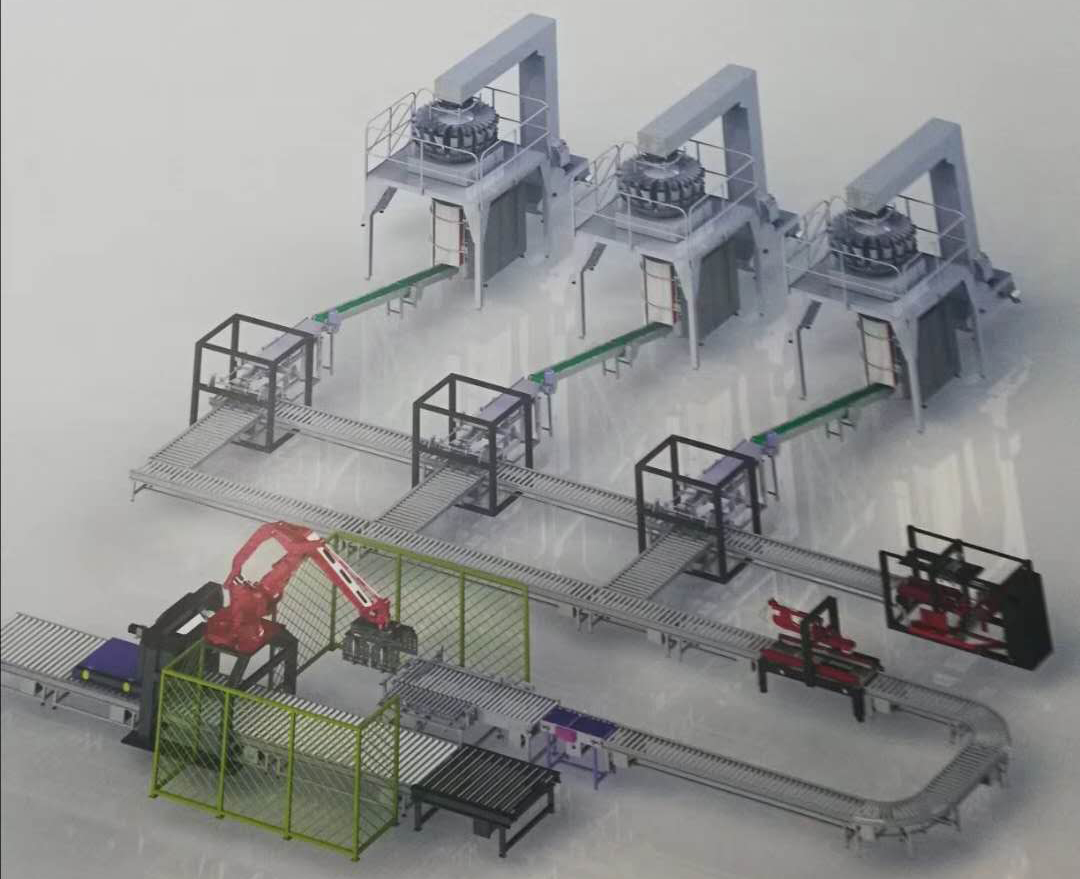

The Automatic Potato Chips Packaging Machine consists of a vertical bag packaging machine, a combination scale (or SPFB2000 weighing machine) and vertical bucket elevator, integrates the functions of weighing, bag-making, edge-folding, filling, sealing, printing, punching and counting, adopts servo motor driven timing belts for film pulling. All the control components adopt international famous brand products with reliable performance. Both transverse and longitudinal sealing mechanism adopt pneumatic system with stable and reliable action. Advanced design ensures that adjustment, operation and maintenance of this machine are very convenient.

Technical Specification

| Model | SPEP-420 | SPEP-520 | SPEP-720 |

| Film width | 140~420mm | 140~520mm | 140~720mm |

| Bag width | 60~200mm | 60~250mm | 60~350mm |

| Bag length | 50~250mm, single film pulling | 50~250mm, single film pulling | 50~250mm, single film pulling |

| Filling range*1 | 10~750g | 10~1000g | 50~2000g |

| Packing Speed*2 | 20~40bpm on PP | 20~40bpm on PP | 20~40bpm on PP |

| Install Voltage | AC 1phase, 50Hz, 220V | AC 1phase, 50Hz, 220V | AC 1phase, 50Hz, 220V |

| Total Power | 3.5KW | 4KW | 5.5KW |

| Air Consumption | 2CFM @6 bar | 2CFM @6 bar | 2CFM @6 bar |

| Dimensions*3 | 1300x1240x1150mm | 1300x1300x1150mm | 1300x1400x1150mm |

| Weight | Approx. 500kg | Approx. 600 kg | Approx. 800 kg |

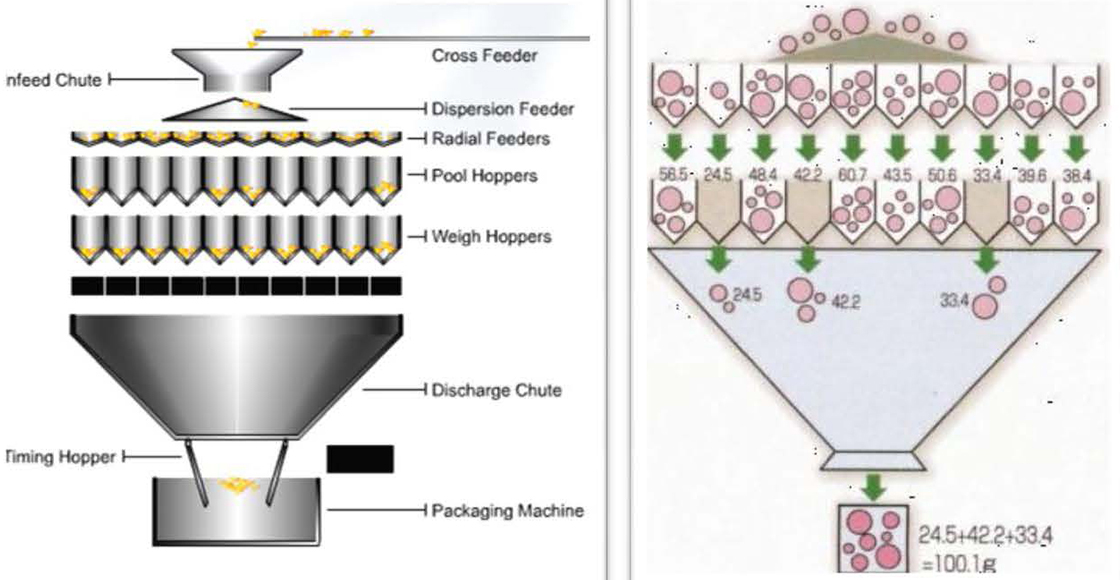

Weighting principle

Packaging diagram

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High-quality first" in mind, we work closely with our prospects and supply them with efficient and specialist companies for Automatic Potato Chips Packaging Machine SPGP-5000D/5000B/7300B/1100 , The product will supply to all over the world, such as: Iran, Cologne, Iraq, To create more creative products, maintain high-quality products and update not only our products but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we offer and to grow stronger together. To be the real winner, starts here!

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.