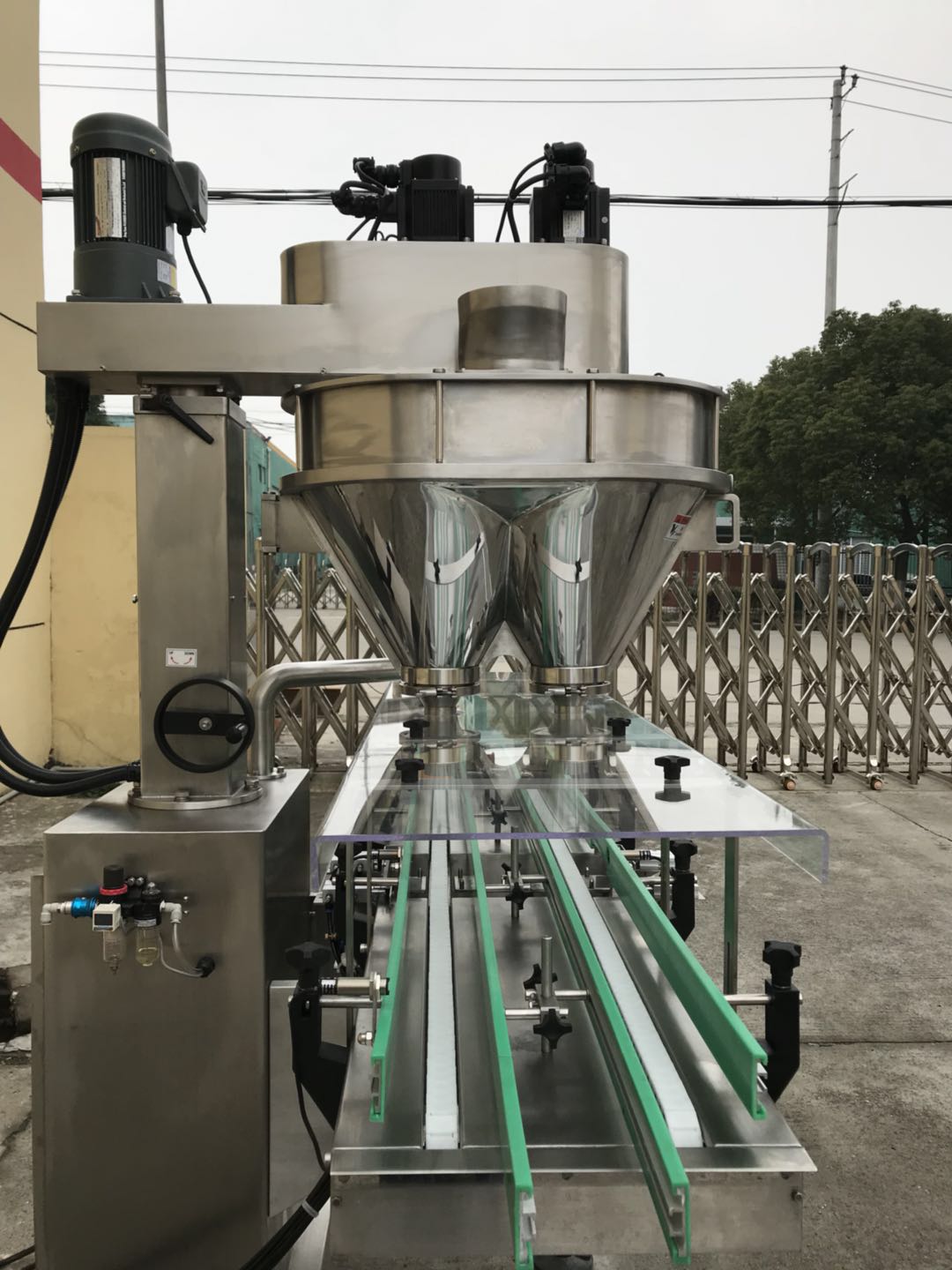

Automatic Powder Auger filling machine (2 lane 2 fillers) Model SPCF-L2-S

Automatic Powder Auger filling machine (2 lane 2 fillers) Model SPCF-L2-S Detail:

Equipment Description

This Auger Filling Machine is a complete, economical solution to your filling production line requirements. can measuring and filling powder and granular. It consists of the Two Filling Head, an independent motorized chain conveyor mounted on a sturdy, stable frame base, and all necessary accessories to reliably move and position containers for filling, dispense the required amount of product, then quickly move the filled containers away to other equipment in your line (e.g., cappers, labelers, etc.).

It is suitable for dry powder filling, fruit powder filling, tea powder filling, albumen powder filling, protein powder filling, meal replacement powder filling, kohl filling, glitter powder filling, pepper powder filling, cayenne pepper powder filling, rice powder filling, flour filling, soy milk powder filling, coffee powder filling, medicine powder filling, pharmacy powder filling, additive powder filling, essence powder filling, spice powder filling, seasoning powder filling and etc.

Main features

Stainless steel structure; The quick disconnecting hopper could be washed easily without tools.

Servo motor drive screw.

PLC, Touch screen and weighing module control.

To save all product’s parameter formula for later use, save 10 sets at most.

Replacing the auger parts, it is suitable for material from super thin powder to granule.

Include handwheel of adjustable height

Main Technical Data

| Model | SP-L2-S | SP-L2-M |

| Dosing mode | Dossing by auger filler | Dual filler filling with online weighing |

| Working Position | 2 lanes+2fillers | 2 lanes+2fillers |

| Filling Weight | 1-500g | 10 – 5000g |

| Filling Accuracy | 1-10g, ≤±3-5%; 10-100g, ≤±2%; 100-500g,≤±1% | ≤100g, ≤±2%; 100-500g,≤±1%; ≥500g,≤±0.5%; |

| Filling Speed | 50-70 bottles/min | 50-70 bottles/min |

| Power Supply | 3P AC208-415V 50/60Hz | 3P, AC208-415V, 50/60Hz |

| Total Power | 2.02kw | 2.87kw |

| Total Weight | 240kg | 400kg |

| Air Supply | 0.05cbm/min, 0.6Mpa | 0.05cbm/min, 0.6Mpa |

| Overall Dimension | 1185×940×1986mm | 1780x1210x2124mm |

| Hopper Volume | 51L | 83L |

Equipment details

Product detail pictures:

Related Product Guide:

Always customer-oriented, and it's our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for Automatic Powder Auger filling machine (2 lane 2 fillers) Model SPCF-L2-S , The product will supply to all over the world, such as: Juventus, Jamaica, Gabon, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.