Automatic Powder Packaging Machine China Manufacturer

Automatic Powder Packaging Machine China Manufacturer Detail:

Video

Equipment Description

This powder packaging machine completes the whole packaging procedure of measuring, loading materials, bagging, date printing, charging (exhausting) and products transporting automatically as well as counting. can be used in powder and granular material. like milk powder, Albumen powder, solid drink, white sugar, dextrose, coffee powder, nutrition powder, enriched food and so on.

Main technical data

Servo drive for film feeding

Synchronous belt by servo drive is more better to avoid the inertia, make sure the film feeding to be more exact, and longer working life and more steady operation.

PLC control system

Program store and search function.

Almost all the operation parameter (such as feeding length, sealing time and speed) could be adjusted, stored and callout.

7 inch touch screen, easy operation system.

The operation is visible for sealing temperature, packaging speed, film feeding status, alarm, bagging count and other main function, such as manual operation, test mode, time & parameter setting.

Film feeding

Open film feeding frame with color mark photo-electricity, automatic correction function to make sure roll film, forming tube and vertical sealing is in the same line, which to reduce material waste. No need to open vertical sealing when correction to save operation time.

Forming tube

Completed set of forming tube for easy and fast changing.

Pouch length auto tracking

Color mark sensor or encoder for auto tracking and length recording, make sure the feeding length will match the setting length.

Heat coding machine

Heat coding machine for auto coding of date and batch.

Alarm and safety setting

Machine stop automatically when door open, no film, no coding tape and etc., to guarantee the safety of operator.

Easy operation

The bag packing machine can match most of balance and measuring system.

Easy and fast to change wearing parts.

Technical specification

| Model | SPB-420 | SPB-520 | SPB-620 | SPB-720 |

| Film width | 140~420mm | 180-520mm | 220-620mm | 420-720mm |

| Bag width | 60~200mm | 80-250mm | 100-300mm | 80-350mm |

| Bag length | 50~250mm | 100-300mm | 100-380mm | 200-480mm |

| Filling range | 10~750g | 50-1500g | 100-3000g | 2-5kg |

| Filling accuracy | ≤ 100g, ≤±2%;100 - 500g, ≤±1%; >500g, ≤±0.5% | ≤ 100g, ≤±2%;100 - 500g, ≤±1%; >500g, ≤±0.5% | ≤ 100g, ≤±2%;100 - 500g, ≤±1%; >500g, ≤±0.5% | ≤ 100g, ≤±2%;100 - 500g, ≤±1%; >500g, ≤±0.5% |

| Packing Speed | 40-80bpm on PP | 25-50bpm on PP | 15-30bpm on PP | 25-50bpm on PP |

| Install Voltage | AC 1phase, 50Hz, 220V | AC 1phase, 50Hz, 220V | AC 1phase, 50Hz, 220V | |

| Total Power | 3.5kw | 4kw | 4.5kw | 5.5kw |

| Air Consumption | 0.5CFM @6 bar | 0.5CFM @6 bar | 0.6CFM @6 bar | 0.8CFM @6 bar |

| Dimensions | 1300x1240x1150mm | 1550x1260x1480mm | 1600x1260x1680mm | 1760x1480x2115mm |

| Weight | 480kg | 550kg | 680kg | 800kg |

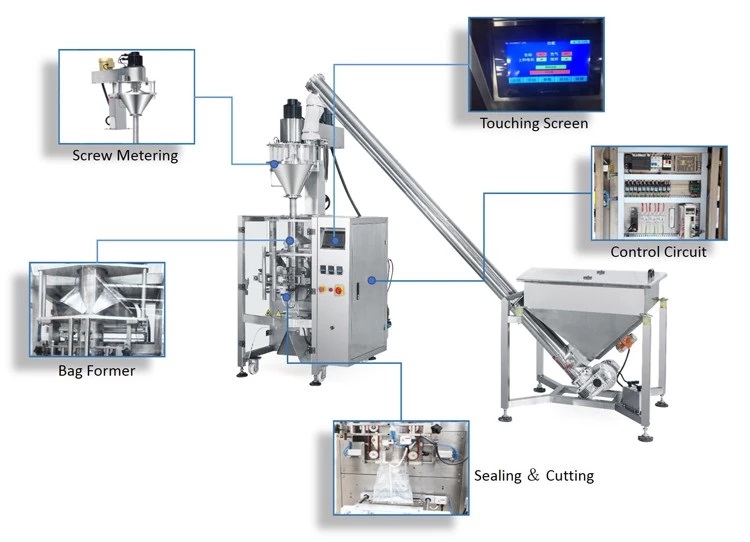

Equipment sketch map

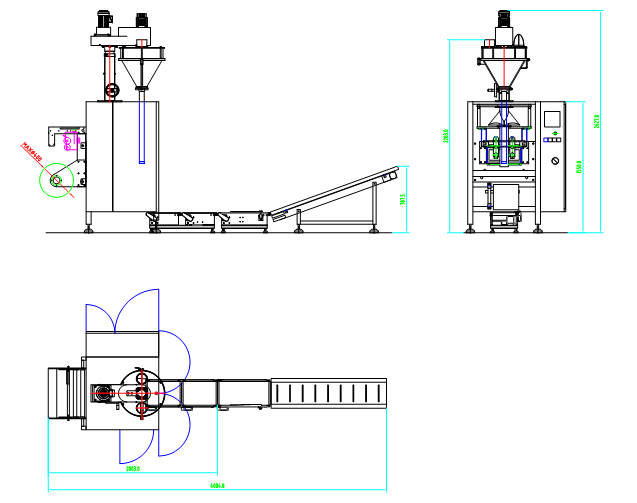

Equipment drawing

Product detail pictures:

Related Product Guide:

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Automatic Powder Packaging Machine China Manufacturer , The product will supply to all over the world, such as: Mauritania, Russia, Accra, We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!