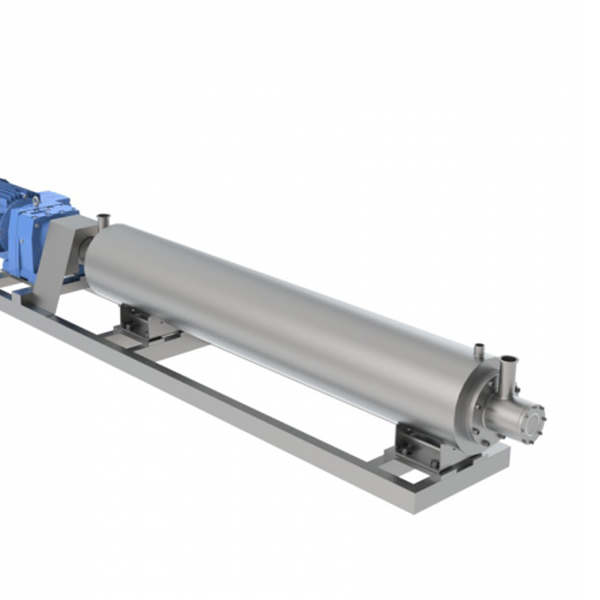

Best quality Liquid Washing Machine Soap - High-precision Two-scrapers Bottom Discharged roller Mill – Shipu Machinery

Best quality Liquid Washing Machine Soap - High-precision Two-scrapers Bottom Discharged roller Mill – Shipu Machinery Detail:

General Flowchart

Main feature

This bottom discharged mill with three rolls and two scrapers are design for professional soap producers. The soap particle size can reach 0.05 mm after milling. The size of milled soap is uniformly distributed, that means 100% of efficiency. The 3 rolls, made from stainless alloy 4Cr, are driven by 3 gear reducers with their own speed. The gear reducers are supplied by SEW, Germany. The clearance between rolls can be adjusted independently; the adjusting error is 0.05 mm max. The clearance is fixed by shrinking sleeves supplied by KTR, Germany, and set screws.

The smashed soap will form flakes by pressure since the mill is bottom discharged. The milling process is no pollution to the environment, low noise, no dropping of soap. The mill is applicable to processing toilet soap, low-fat soap and translucent soap.

This mill now is in the top of similar machine in the world.

Mechanical design:

- The rolls are driven by their own gear reducers. The clearance between adjacent rolls is fixed by shrinking sleeves supplied by KTR, Germany. No change of clearance during operation to guarantee the optimal milling effect.

- The rolls are water cooled. The mechanical shaft seal is made in Wuxi, China;

- Roll diameter is 405 mm, effective milling length 900 mm. The thickness of roll is 60 mm.

- Rolls are made from stainless alloy 4Cr. After The roll is heat treated and quenched, the hardness of roll is Shore 70-72;

- There are two scrapers. The 1st scraper is over slow roll to feed the soap onto second roll. The 2nd scraper is at fast roll for discharge of the milled soap to increase the output. No dropping of soap and soap dust flying since the soap scraped off falls down ward. So it is suitable for low fat soap, such as translucent soap, and high water content soap;

- 3 gear reducers are supplied by SEW, Germany;

- Bearings are SKF, Switzerland;

- Shrinking sleeves are by KTR, Germany;

- Rotating speed: Fast roll 203 r/min

Medium roll 75 r/min

Slow roll 29 r/min.

Electrical:

- Switches, contactors are supplied by Schneider, France;

- Motors : Fast roll 18.5 kW

Medium roll 15 kW

Slow roll 7.5 kW

EQuipment details

Product detail pictures:

Related Product Guide:

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for Best quality Liquid Washing Machine Soap - High-precision Two-scrapers Bottom Discharged roller Mill – Shipu Machinery , The product will supply to all over the world, such as: Tunisia, Croatia, Poland, With the first-class solutions, excellent service, fast delivery and the best price, we've won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.