China wholesale Dmf Recycling Plant - Surface Scraped Heat Exchanger-SPK – Shipu Machinery

China wholesale Dmf Recycling Plant - Surface Scraped Heat Exchanger-SPK – Shipu Machinery Detail:

Main feature

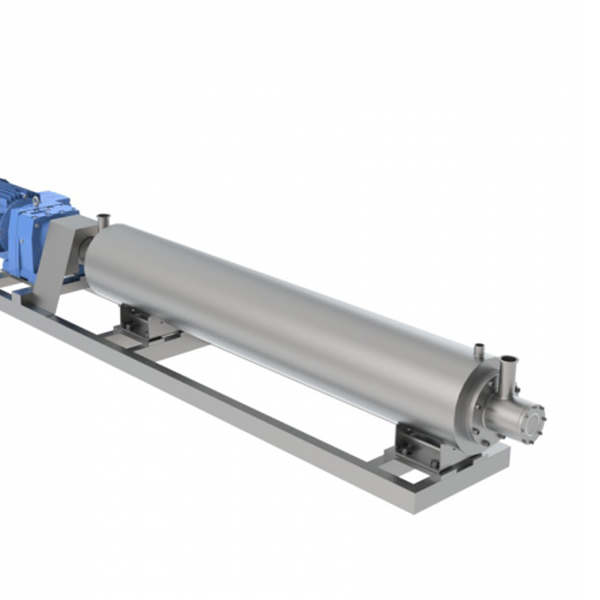

A horizontal scraper heat exchanger that can be used to heat or cool products with a viscosity of 1000 to 50000cP is especially suitable for medium viscosity products. Its horizontal design allows it to be installed in a cost-effective manner. It is also easy to repair because all components can be maintained on the ground.

Coupling connection

Durable scraper material and process

High precision machining process

Rugged heat transfer tube material and inner hole process treatment

The heat transfer tube cannot be disassembled and replaced separately

Adopt Rx series helical gear reducer

Concentric installation, higher installation requirements

Follow 3A design standards

It shares many interchangeable parts like bearing, mechanical seal and scraper blades. The basic design consists of a pipe-in-pipe cylinder with inner pipe for product and outer pipe for cooling refrigerant. A rotating shaft with scraper blades provides the necessary scraping function of heat transfer, mixing and emulsification.

Technical spec.

Annular Space : 10 – 20mm

Total Heat Exchanger Area : 1.0 m2

Max Product Tested Pressure : 60 bar

Approximate Weight : 1000 kg

Approx Dimensions : 2442 mm L x 300 mm dia.

Required Compressor Capacity : 60kw at -20°C

Shaft Speed : VFD drive 200 ~ 400 rpm

Blade Material : PEEK, SS420

Product detail pictures:

Related Product Guide:

In an effort to provide you advantage and enlarge our business enterprise, we even have inspectors in QC Staff and assure you our greatest provider and item for China wholesale Dmf Recycling Plant - Surface Scraped Heat Exchanger-SPK – Shipu Machinery , The product will supply to all over the world, such as: Bogota, Leicester, Afghanistan, We've customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Ought to you want anything, don't hesitate to contact us.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!