Chinese Professional Gas Absorption Tower - Surface Scraped Heat Exchanger-SPK – Shipu Machinery

Chinese Professional Gas Absorption Tower - Surface Scraped Heat Exchanger-SPK – Shipu Machinery Detail:

Main feature

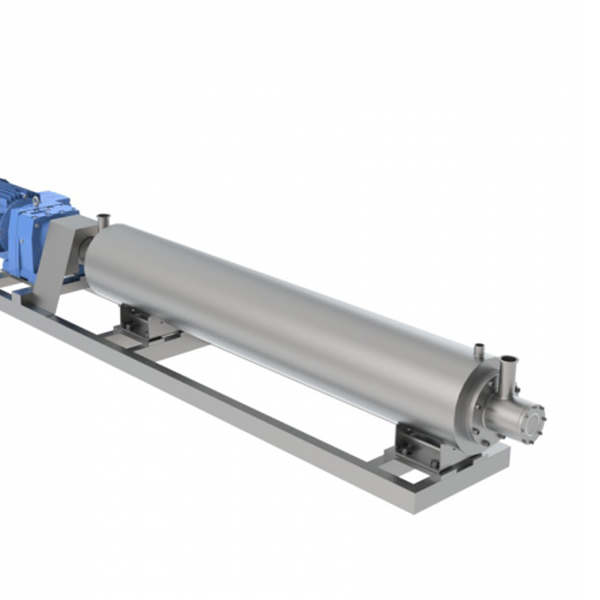

A horizontal scraper heat exchanger that can be used to heat or cool products with a viscosity of 1000 to 50000cP is especially suitable for medium viscosity products. Its horizontal design allows it to be installed in a cost-effective manner. It is also easy to repair because all components can be maintained on the ground.

Coupling connection

Durable scraper material and process

High precision machining process

Rugged heat transfer tube material and inner hole process treatment

The heat transfer tube cannot be disassembled and replaced separately

Adopt Rx series helical gear reducer

Concentric installation, higher installation requirements

Follow 3A design standards

It shares many interchangeable parts like bearing, mechanical seal and scraper blades. The basic design consists of a pipe-in-pipe cylinder with inner pipe for product and outer pipe for cooling refrigerant. A rotating shaft with scraper blades provides the necessary scraping function of heat transfer, mixing and emulsification.

Technical spec.

Annular Space : 10 – 20mm

Total Heat Exchanger Area : 1.0 m2

Max Product Tested Pressure : 60 bar

Approximate Weight : 1000 kg

Approx Dimensions : 2442 mm L x 300 mm dia.

Required Compressor Capacity : 60kw at -20°C

Shaft Speed : VFD drive 200 ~ 400 rpm

Blade Material : PEEK, SS420

Product detail pictures:

Related Product Guide:

Attaining consumer satisfaction is our company's purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for Chinese Professional Gas Absorption Tower - Surface Scraped Heat Exchanger-SPK – Shipu Machinery , The product will supply to all over the world, such as: Honduras, Estonia, South Africa, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.