DCS Control System

System Description

DMF recovery process is a typical chemical distillation process, characterized by a large degree of correlation between process parameters and a high requirement for recovery indicators. From the current situation, the conventional instrument system is difficult to achieve real-time and effective monitoring of the process, so the control is often unstable and the composition exceeds the standard, which affects the production efficiency of enterprises. For this reason, our company and Beijing University of Chemical Technology jointly developed THE DCS control system of DMF recycling engineering computer.

Computer decentralized control system is the most advanced control mode recognized by the international control circle. In recent years, we have developed a two-tower double-effect computer control system for DMF recovery process, DMF-DCS (2), and a three-tower three-effect computer control system, which can adapt to the industrial production environment and has very high reliability. Its input greatly stabilizes the production of recycling process and plays an important role in improving the output and quality of products and reducing energy consumption.

At present, the system has been successfully implemented in more than 20 large synthetic leather enterprises, and the earliest system has been in stable operation for more than 17 years.

System structure

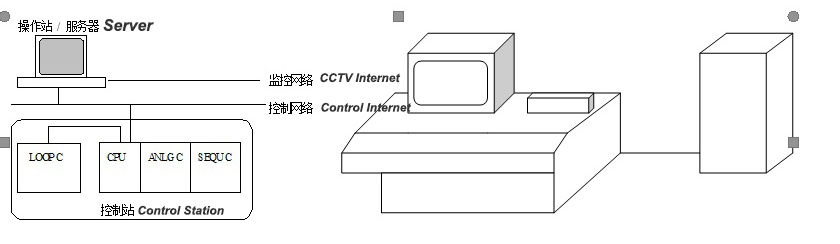

Distributed computer control system (DCS) is a widely accepted advanced control method. It usually consists of control station, control network, operation station and monitoring network. Broadly speaking, DCS can be divided into three types: instrument type, PLC type and PC type. Among them, PLC has a very high industrial reliability and more and more applications, especially since the 1990s, many famous PLC increased analog processing and PID control functions, thus making it more competitive.

The COMPUTER control system of DMF recycling process is based on PC-DCS, using German SIEMENS system as the control station, and ADVANTECH industrial computer as the operating station, equipped with large screen LED, printer and engineering keyboard. A high-speed control communication network is adopted between the operation station and the control station.

Control function

The control station is composed of parameter data collector ANLGC, switch parameter data collector SEQUC, intelligent loop controller LOOPC and other decentralized control methods. All kinds of controllers are equipped with microprocessors, so they can work normally in backup mode in case of CPU failure of the control station, fully guaranteeing the reliability of the system.