Double shafts paddle mixer Model SPM-P

Double shafts paddle mixer Model SPM-P Detail:

简要说明 Descriptive abstract

TDW无重力混合机又称桨叶混合机,适用于粉料与粉料、颗粒与颗粒、颗粒与粉料及添加少量液体的混合,广泛应用于食品、化工、干粉砂浆、农药、饲料及电池等行业。该机是高精度混合设备,对混合物适应性广,对比重、配比、粒径差异大的物料能混合均匀,对配比差异达到1:1000~10000甚至更高的物料能很好的混合。本机增加破碎装置后对颗粒物料能起到部分破碎的作用,材质可选316L,304,201,碳钢等.

TDW non gravity mixer is called double-shaft paddle mixer too, it is widely applied in mixing powder and powder, granule and granule, granule and powder and a bit liquid. It is used for food, chemical, pesticide, feeding stuff and battery etc. It is high precision mixing equipment and adapts to mix different sizes of materials with different specific gravity, the proportion of formula and mixing uniformity. It can be a very good mix for which ratio reaches 1:1000~10000 or more. The machine can make the partial of granules broken after crushing equipment added.

Main features

High active: Rotate reversely and throw materials to different angles,mixing time 1-3min.

High uniformity: Compact design and rotated shafts be filled with hopper, mixing uniformity up to 99%.

Low residue: Only 2-5mm gap between shafts and wall, open-type discharging hole.

Zero leakage: Patent design and ensure the rotating axle & discharing hole w/o leakage.

Full clean: Full weld and polishing process for mixing hopper, w/o any fastening piece like screw, nut.

Nice profile: the whole machine is made by 100% stainless steel to make its profile elegant except bearing seat.

主要参数 Main Technical Data

|

型号/Model |

SPM-P300 |

SPM-P500 |

SPM-P1000 |

SPM-P1500 |

SPM-P2000 |

SPM-P3000 |

|

有效容量/ Effective Volume |

300L |

500L |

1000L |

1500L |

2000L |

3000L |

|

全容积/Fully Volume |

420L |

650L |

1350L |

2000L |

2600L |

3800L |

|

装载系数/Load Factor |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

|

转速/Turning Speed |

53rpm |

53rpm |

45rpm |

45rpm |

39rpm |

39rpm |

|

整机重量/Total Weight |

660kg |

900kg |

1380kg |

1850kg |

2350kg |

2900kg |

|

整机功率/Total Power |

5.5kw |

7.5kw |

11kw |

15kw |

18.5kw |

22kw |

|

总长/Length(L) |

1330 |

1480 |

1730 |

2030 |

2120 |

2420 |

|

总宽/Width(W) |

1130 |

1350 |

1590 |

1740 |

2000 |

2300 |

|

总高/Height(H) |

1030 |

1220 |

1380 |

1480 |

1630 |

1780 |

|

筒体半径/(R) |

277 |

307 |

377 |

450 |

485 |

534 |

|

电源/Power Supply |

3P AC208-415V 50/60Hz |

|||||

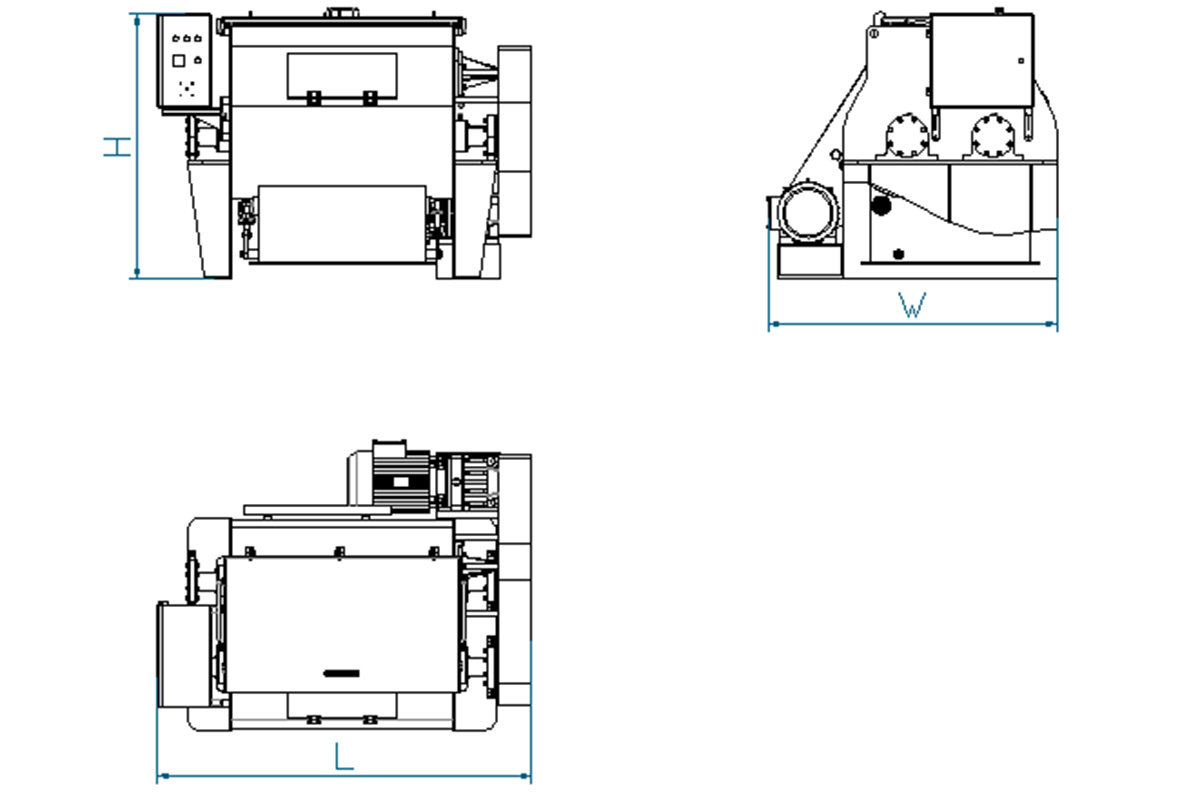

外观尺寸图 Dimension drawing

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Double shafts paddle mixer Model SPM-P , The product will supply to all over the world, such as: South Africa, New Zealand, Liverpool, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We are able to also offer you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and products, please speak to us by sending us emails or call us quickly. In an effort to know our products and company extra, you may come to our factory to view it. We will generally welcome guests from all over the world to our business to create business relations with us. Please feel cost-free to speak to us for small business and we believe we'll share the best trading experience with all our merchants.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.