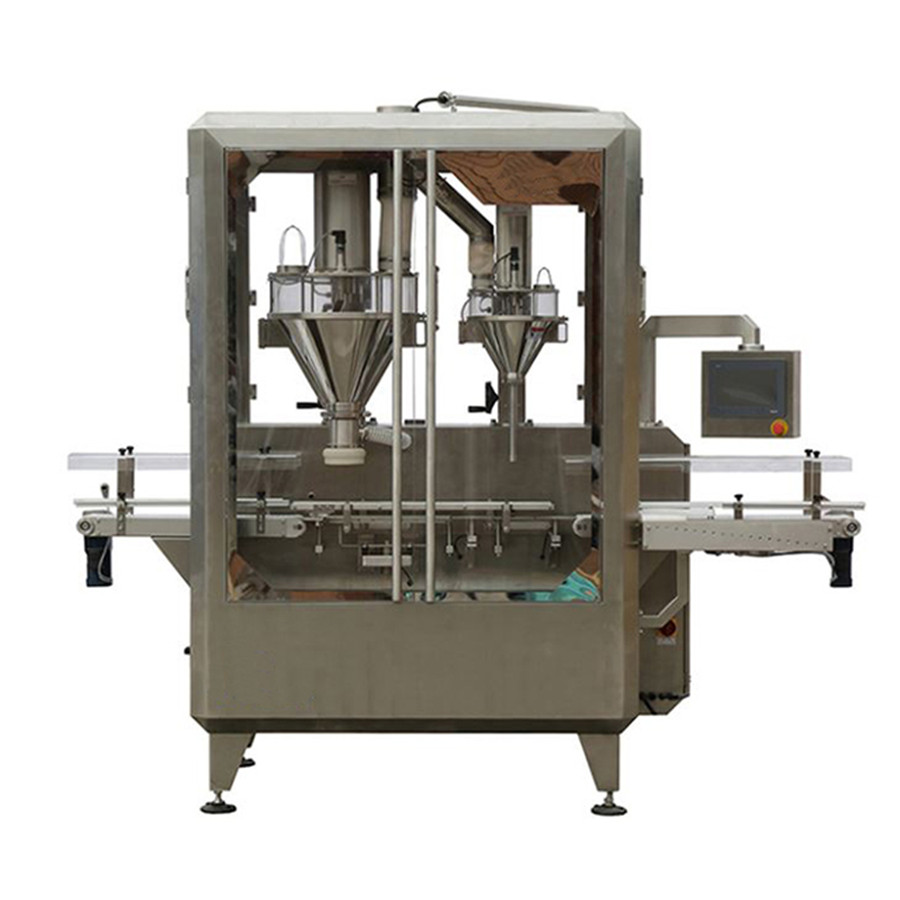

Factory Cheap Hot Formula Milk Powder Packing Machine - Automatic Powder Can Filling Machine (1 line 2fillers) Model SPCF-W12-D135 – Shipu Machinery

Factory Cheap Hot Formula Milk Powder Packing Machine - Automatic Powder Can Filling Machine (1 line 2fillers) Model SPCF-W12-D135 – Shipu Machinery Detail:

Main features

One line dual fillers, Main & Assist filling to keep work in high-precision.

Can-up and horizontal transmitting is controlled by servo and pneumatic system, be more accurate, more speed.

Servo motor and servo driver control the screw, keep stable and accurate

Stainless steel structure, Split hopper with polishing inner-out make it to cleaned easily.

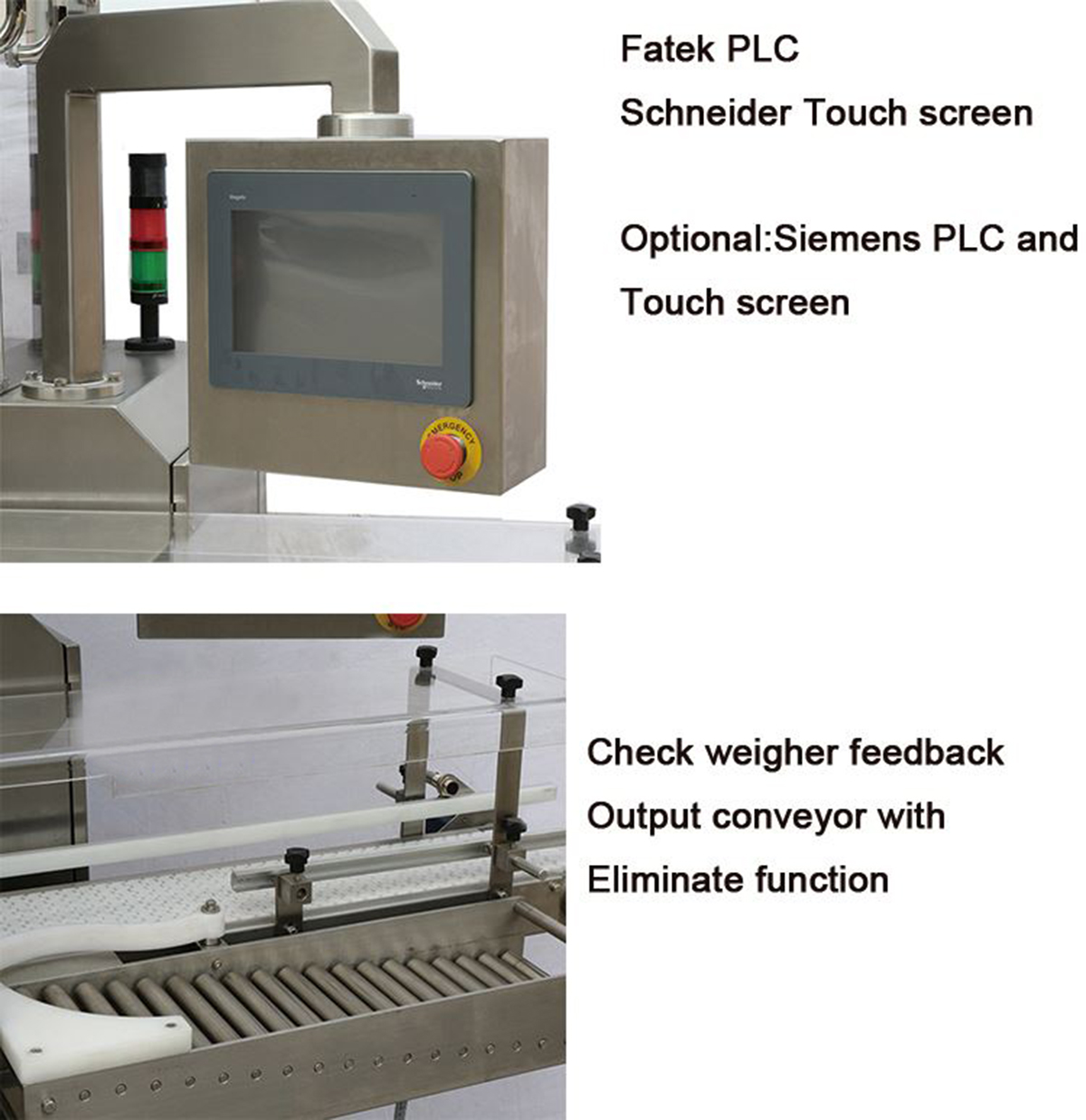

PLC & touch screen make it be easy of operation.

Fast-respond weighing system make the strongpoint to real

The handwheel make the exchange of different filings to be easily.

Dust-collecting cover meet the pipeline and protect environment to pollution.

Horizontal straight design make the machine in little area

Settled screw setup make no metal pollution in producing

Process: can-into → can-up → vibration → filling → vibration → vibration → weighing & tracing → reinforce → weight checking → Can-out

With whole system central control system.

Main technical data

|

Dosing mode |

Dual filler filling with online weighing |

|

Filling Weight |

100 – 2000g |

|

Container Size |

Φ60-135mm; H 60-260mm |

|

Filling Accuracy |

100-500g, ≤±1g; ≥500g,≤±2g |

|

Filling Speed |

Above 50 cans/min(#502),Above 60 cans/min(#300 ~ #401) |

|

Power Supply |

3P AC208-415V 50/60Hz |

|

Total Power |

3.4 kw |

|

Total Weight |

450kg |

|

Air Supply |

6kg/cm 0.2cbm/min |

|

Overall Dimension |

2650×1040×2300mm |

|

Hopper Volume |

50L(Main) 25L (Assist) |

Main function

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and advancement, we will build a prosperous future with each other with your esteemed firm for Factory Cheap Hot Formula Milk Powder Packing Machine - Automatic Powder Can Filling Machine (1 line 2fillers) Model SPCF-W12-D135 – Shipu Machinery , The product will supply to all over the world, such as: Greek, Algeria, Saudi Arabia, Our company always committed to meet your quality demand, price points and sales target. Warmly welcome you open the boundaries of communication. It is our great pleasure to service you if you need a trusted supplier and value information.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.