Factory Cheap Hot Packed Tower Absorption – Pin Rotor Machine Benefits-SPCH – Shipu Machinery

Factory Cheap Hot Packed Tower Absorption – Pin Rotor Machine Benefits-SPCH – Shipu Machinery Detail:

Easy to Maintain

The overall design of the SPCH pin rotor facilitates easy replacement of wearing parts during repair and maintenance. The sliding parts are made of materials that ensure very long durability.

Materials

The product contact parts are made of high-quality stainless steel. The product seals are balanced mechanical seals and food-grade O-rings. The sealing surface is made of hygienic silicon carbide, and the movable parts are made of chromium carbide.

Flexibility

The SPCH pin rotor machine is an excellent production solution to ensure proper crystallization and consistency for a wide range of margarine and shortening products. Our SPCH pin rotor machine offers flexibility to the production process in very important way. Adjustments can be made to change the level of intensity and the duration of kneading. This allows you to change the type of oil, depending on availability and demand on the market. With this flexibility, you can take advantage of oil price fluctuations without compromising product quality.

Working Principle

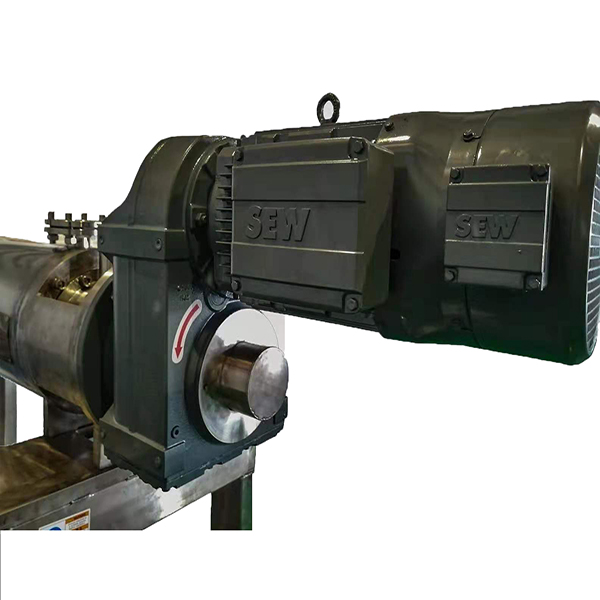

SPCH pin rotor adopts a cylindrical pin stirring structure to ensure that the material has sufficient stirring time to break the network structure of the solid fat crystal and refine the crystal grains. The motor is a variable-frequency speed regulating motor. The mixing speed can be adjusted according to different solid fat content, which can meet the production requirements of various formulations of margarine manufacturers according to market conditions or consumer groups.

When the semi-finished product of grease containing crystal nuclei enters the kneader, the crystal will grow after a period of time. Before forming the overall network structure, perform mechanical stirring and kneading to break the originally formed network structure, make it recrystallize, reduce the consistency and increase the plasticity.

Pin Rotor-Spch

| Technical parameters | Technical Spec. | Unit | 30L | 50L | 80L |

| The rated capacity | Nominal Volume | L | 30 | 50 | 80 |

| Main motor power | Main Power | kw | 7.5 | 7.5 | 9.2 or 11 |

| The spindle diameter | Dia. Of Main Shaft | mm | 72 | 72 | 72 |

| Stirring bar clearance | Pin Gap Space | mm | 6 | 6 | 6 |

| The mixing bar is clearance with the inner wall of the barrel | Pin-Inner Wall Space | m2 | 5 | 5 | 5 |

| Diameter/length of cylinder body | Inner Dia./Length of Cooling Tube | mm | 253/660 | 253/1120 | 260/1780 |

| The number of stir rod rows | Rows of Pin | pc | 3 | 3 | 3 |

| Stirring rod spindle speed | Norminal Pin Rotor Speed | rpm | 50-340 | 50-340 | 50-340 |

| Maximum working pressure (product side) | Max.Working Pressure (material side) | bar | 60 | 60 | 60 |

| Maximum working pressure (heat preservation water side) | Max.Working Pressure (hot water side) | bar | 5 | 5 | 5 |

| Product pipe interface dimensions | Processing Pipe Size | DN50 | DN50 | DN50 | |

| Interface dimensions of insulated water pipes | Water Supply Pipe Size | DN25 | DN25 | DN25 | |

| The machine size | Overall Dimension | mm | 1840*580*1325 | 2300*580*1325 | 2960*580*1325 |

| The weight | Gross Weight | kg | 450 | 600 | 750 |

Machine drawing

Product detail pictures:

Related Product Guide:

With a sound business credit, excellent after-sales service and modern manufacturing facilities, we have earned an excellent reputation among our customers across the world for Factory Cheap Hot Packed Tower Absorption – Pin Rotor Machine Benefits-SPCH – Shipu Machinery , The product will supply to all over the world, such as: Swiss, Mozambique, Frankfurt, We provide good quality but unbeatable low price and the best service. Welcome to post your samples and color ring to us .We will produce the goods according to your request. If you are interested in any products we offer, please feel free to contact us directly by mail, fax, telephone or internet. We are here to answer your questions from Monday to Saturday and looking forward to cooperating with you.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.