Factory Outlets Biscuit Sealing Machine – Automatic Pillow Packaging Machine – Shipu Machinery

Factory Outlets Biscuit Sealing Machine – Automatic Pillow Packaging Machine – Shipu Machinery Detail:

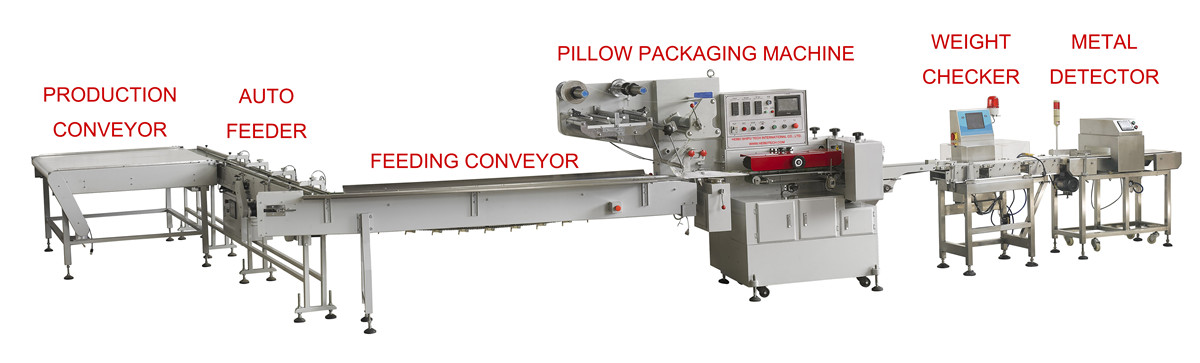

Working process

Packing Material:PAPER /PE OPP/PE, CPP/PE, OPP/CPP, OPP/AL/PE ,and other heat-sealable packing materials.

Electric parts brand

|

Item |

Name |

Brand |

Origin country |

|

1 |

Servo motor |

Panasonic |

Japan |

|

2 |

Servo driver |

Panasonic |

Japan |

|

3 |

PLC |

Omron |

Japan |

|

4 |

Touch Screen |

Weinview |

Taiwan |

|

5 |

Temperature board |

Yudian |

China |

|

6 |

Jog button |

Siemens |

Germany |

|

7 |

Start & Stop button |

Siemens |

Germany |

WE may use same high level international brand for electric parts.

Characteristic

● The machine is with very good synchronism, PLC control, Omron brand, Japan.

● Adopting photoelectric sensor to detect the eye mark, tracking fast and accurately

● Date coding is equipped within the price.

● Reliable and stable system, low maintenance, programmable controller.

● HMI display contains length of packing film, speed, output, temperature of packing etc.

● Adopt PLC control system, reduce mechanical contact.

● Frequency control, convenient and simple.

● Bidirectional automatic tracking, color control patch by photoelectric detection.

Machine specifications

| Model SPA450/120 |

| Max Speed 60-150 packs/minThe speed depend on the shape and size of products and film used |

| 7” size digital display |

| People friend interface control for easy to operate |

| Double way tracing eye-mark for printing film, accurate control bag length by servo motor, this make operate convenient to run the machine ,save time |

| Film roll can be adjustable to guarantee the longitudinal sealing in line and perfect |

| Japan brand ,Omron photocell ,with long time durability and accurate monitoring |

| New design longitudinal sealing heating system ,guarantee stable sealing for center |

| With human friendly glass like cover on end sealing, to protect operate avoid of damage |

| 3 sets of Japan brand temperature control units |

| 60cm discharge conveyor |

| Speed indicator |

| Bag length indicator |

| All parts are stainless steel nos 304 pertaining on contacting the product |

| 3000mm in-feeding conveyor |

| Our company, introduced Tokiwa technology, with 26 years of experience, exported to more than 30 countries, we welcome your visiting to our factory at any time. |

Main technical data

|

Model |

SPA450/120 |

|

Max film width(mm) |

450 |

|

Packaging rate(bag/min) |

60-150 |

|

Bag length(mm) |

70-450 |

|

Bag width(mm) |

10-150 |

|

Product height(mm) |

5-65 |

|

Power voltage(v) |

220 |

|

Total installed power(kw) |

3.6 |

|

Weight(kg) |

1200 |

|

Dimensions (LxWxH) mm |

5700*1050*1700 |

Equiment details

Product detail pictures:

Related Product Guide:

Every member from our high efficiency sales team values customers' needs and business communication for Factory Outlets Biscuit Sealing Machine – Automatic Pillow Packaging Machine – Shipu Machinery , The product will supply to all over the world, such as: Cape Town, Slovenia, Argentina, We've more than 10 years exported experience and our products and solutions have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!