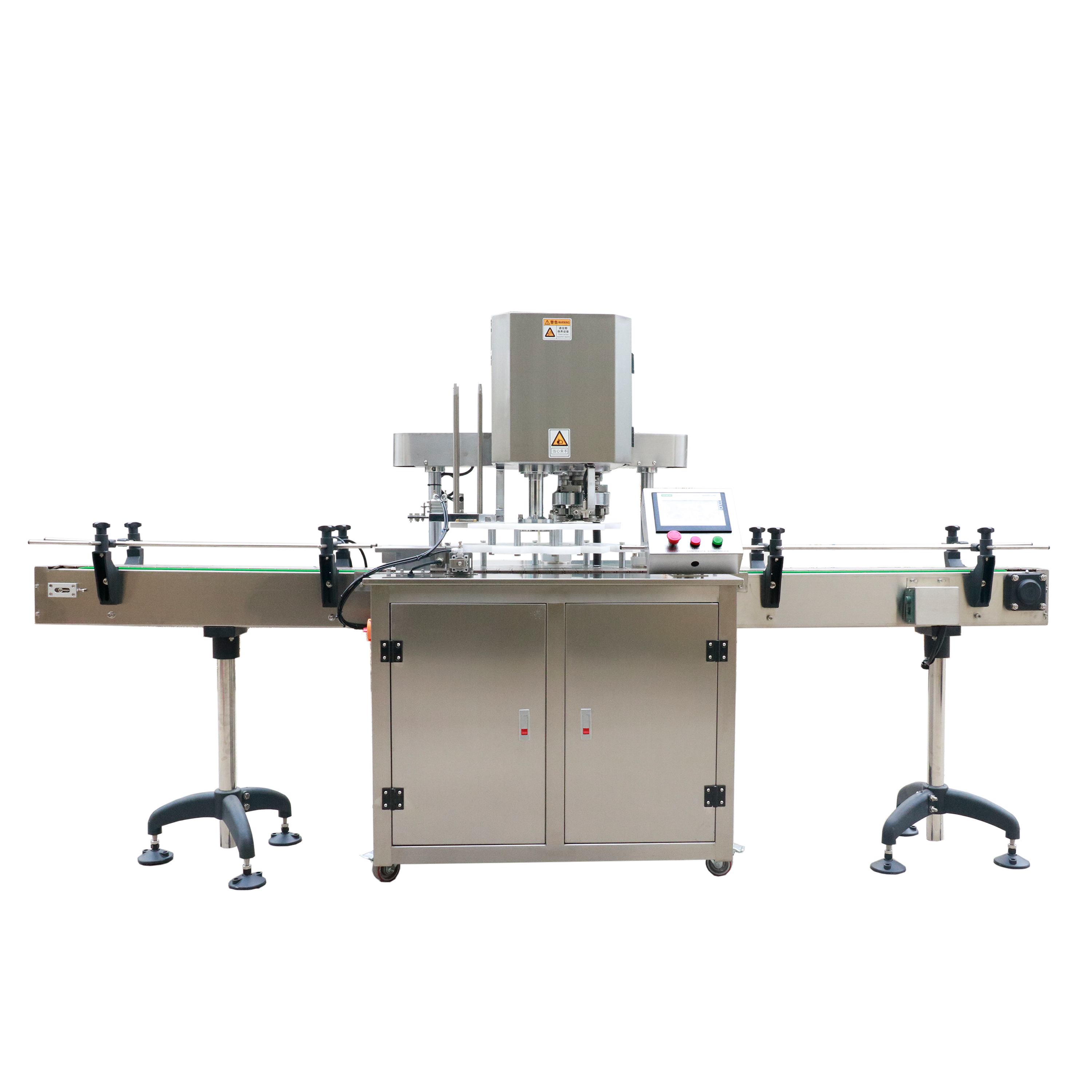

Factory Outlets Health Care Product Filling Machine - SPAS-100 Automatic Can Seaming Machine – Shipu Machinery

Factory Outlets Health Care Product Filling Machine - SPAS-100 Automatic Can Seaming Machine – Shipu Machinery Detail:

There are two model of this automatic can sealing machine, one is standard type, without dust protection, the sealing speed is fixed; the other one is high speed type, with dust protection, speed is adjustable by frequency inverter.

Performance characteristics

With two pairs (four) of seaming rolls, the cans are stationary without rotating while the seaming rolls rotate at high speed during seaming;

Different-sized ring-pull cans can be seamed by replacing accessories like lid-pressing die, can clamp disc and lid-dropping device;

The machine is highly automatic and easily operated with VVVF, PLC control and human- machine interface touch panel;

Can-lid interlock control: corresponding lid is given only when there is a can, and no lid no can;

The machine will stop in the case of no lid: it can automatically stop when no lid is dropped by the lid-dropping device so as to avoid seizing of lid-pressing die by the can and parts damage of seaming mechanism;

The seaming mechanism is driven by synchronous belt, which allows simple maintenance and low noise;

The continuously-variable conveyor is simple in structure and easy to operate and maintain;

The outer housing and main parts are made of 304 stainless steel to meet hygienic requirements of food and drugs.

Technical Parameters

|

Production capacity |

Standard: 35 cans/min.(fixed speed) |

|

High speed: 30-50 cans/min (speed adjustable by frequency inverter) |

|

|

Applicable range |

Can diameter: φ52.5-φ100mm ,φ83-φ127mm Can height: 60-190mm (Special specifications can be customized.) |

|

Voltage |

3P/380V/50Hz |

|

Power |

1.5kw |

|

Total Weight |

500kg |

|

Overall dimensions |

1900(L)×710(W)×1500(H)mm |

|

Overall dimensions |

1900(L)×710(W)×1700(H)mm ( Framed) |

|

Working pressure (compressed air) |

≥0.4Mpa About 100L/min |

Equipment details

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for Factory Outlets Health Care Product Filling Machine - SPAS-100 Automatic Can Seaming Machine – Shipu Machinery , The product will supply to all over the world, such as: kazan, Johannesburg, Liberia, Due to the changing trends in this field, we involve ourselves into products trade with dedicated efforts and managerial excellence. We maintain timely delivery schedules, innovative designs, quality and transparency for our customers. Our moto is to deliver quality products within stipulated time.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.