Factory source Granola Bar Packaging Machine - Automatic Liquid Packaging Machine Model SPLP-7300GY/GZ/1100GY – Shipu Machinery

Factory source Granola Bar Packaging Machine - Automatic Liquid Packaging Machine Model SPLP-7300GY/GZ/1100GY – Shipu Machinery Detail:

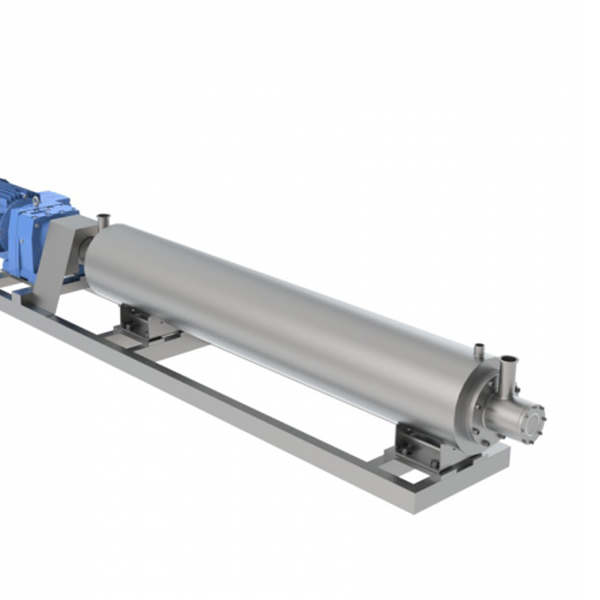

Equipment description

This unit is developed for the need of metering and filling of high viscosity media. It is equipped with servo rotor metering pump for metering with the function of automatic material lifting and feeding, automatic metering and filling and automatic bag-making and packaging, and is also equipped with the memory function of 100 product specifications, the switchover of weight specification can be realized just by one-key stroke.

Application

Suitable materials: Tomato paste packaging, chocolate packaging, shortening/ghee packaging, honey packaging, sauce packaging and etc.

Technical Spec.

|

Model |

Bag size mm |

Metering range |

Measuring accuracy |

Packaging speed bags/min |

|

SPLP7300GY |

(150~500)*(100~350) |

100-5000g |

≤0.5% |

8~25 |

|

SPLP 7300GZ |

(150~500)*(100~350) |

100-5000g |

≤0.5% |

8-15 |

|

SPLP 1100GY |

(200~1000)*(350~750) |

0.5-25kg |

≤0.5% |

3-8 |

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for Factory source Granola Bar Packaging Machine - Automatic Liquid Packaging Machine Model SPLP-7300GY/GZ/1100GY – Shipu Machinery , The product will supply to all over the world, such as: Japan, Surabaya, Iraq, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!