Factory source Granola Bar Packaging Machine - Automatic Pillow Packaging Machine – Shipu Machinery

Factory source Granola Bar Packaging Machine - Automatic Pillow Packaging Machine – Shipu Machinery Detail:

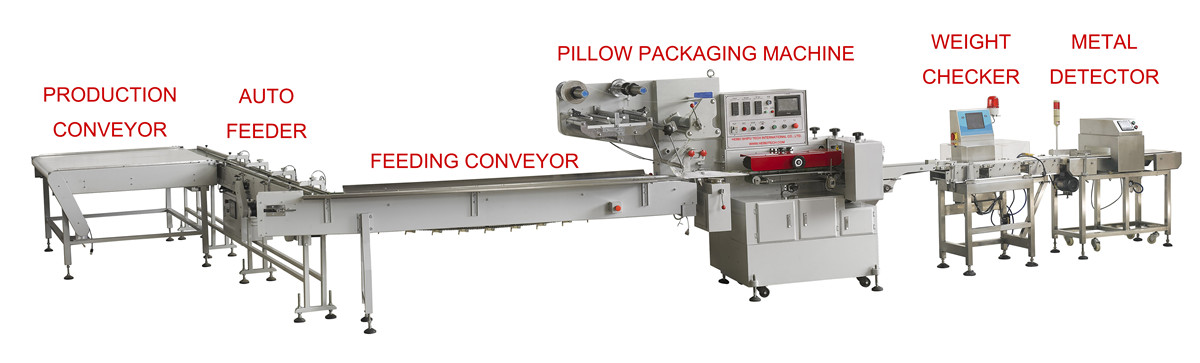

Working process

Packing Material:PAPER /PE OPP/PE, CPP/PE, OPP/CPP, OPP/AL/PE ,and other heat-sealable packing materials.

Suitable for pillow packing machine, cellophane packing machine, overwrapping machine, biscuit packing machine, instant noodles packing machine, soap packing machine and etc.

Electric parts brand

|

Item |

Name |

Brand |

Origin country |

|

1 |

Servo motor |

Panasonic |

Japan |

|

2 |

Servo driver |

Panasonic |

Japan |

|

3 |

PLC |

Omron |

Japan |

|

4 |

Touch Screen |

Weinview |

Taiwan |

|

5 |

Temperature board |

Yudian |

China |

|

6 |

Jog button |

Siemens |

Germany |

|

7 |

Start & Stop button |

Siemens |

Germany |

WE may use same high level international brand for electric parts.

Characteristic

● The machine is with very good synchronism, PLC control, Omron brand, Japan.

● Adopting photoelectric sensor to detect the eye mark, tracking fast and accurately

● Date coding is equipped within the price.

● Reliable and stable system, low maintenance, programmable controller.

● HMI display contains length of packing film, speed, output, temperature of packing etc.

● Adopt PLC control system, reduce mechanical contact.

● Frequency control, convenient and simple.

● Bidirectional automatic tracking, color control patch by photoelectric detection.

Machine specifications

| Model SPA450/120 |

| Max Speed 60-150 packs/minThe speed depend on the shape and size of products and film used |

| 7” size digital display |

| People friend interface control for easy to operate |

| Double way tracing eye-mark for printing film, accurate control bag length by servo motor, this make operate convenient to run the machine ,save time |

| Film roll can be adjustable to guarantee the longitudinal sealing in line and perfect |

| Japan brand ,Omron photocell ,with long time durability and accurate monitoring |

| New design longitudinal sealing heating system ,guarantee stable sealing for center |

| With human friendly glass like cover on end sealing, to protect operate avoid of damage |

| 3 sets of Japan brand temperature control units |

| 60cm discharge conveyor |

| Speed indicator |

| Bag length indicator |

| All parts are stainless steel nos 304 pertaining on contacting the product |

| 3000mm in-feeding conveyor |

| Our company, introduced Tokiwa technology, with 26 years of experience, exported to more than 30 countries, we welcome your visiting to our factory at any time. |

Main technical data

|

Model |

SPA450/120 |

|

Max film width(mm) |

450 |

|

Packaging rate(bag/min) |

60-150 |

|

Bag length(mm) |

70-450 |

|

Bag width(mm) |

10-150 |

|

Product height(mm) |

5-65 |

|

Power voltage(v) |

220 |

|

Total installed power(kw) |

3.6 |

|

Weight(kg) |

1200 |

|

Dimensions (LxWxH) mm |

5700*1050*1700 |

Equiment details

Product detail pictures:

Related Product Guide:

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Factory source Granola Bar Packaging Machine - Automatic Pillow Packaging Machine – Shipu Machinery , The product will supply to all over the world, such as: Zimbabwe, California, Sheffield, If you are for any reason unsure which product to select, do not hesitate to contact us and we are going to be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We have been looking for more and more customers to create the glorious future.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!