High Quality Dma Recovery Plant - Sheet margarine packaging line – Shipu Machinery

High Quality Dma Recovery Plant - Sheet margarine packaging line – Shipu Machinery Detail:

Margarine Production Process

Margarine production includes two parts: raw material preparation and cooling and plasticizing. The main equipment includes preparation tanks, HP pump, votator (scraped surface heat exchanger), pin rotor machine, refrigeration unit, margarine filling machine and etc.

The former process is the mixture of the oil phase and the water phase, the measurement and the mixture emulsification of the oil phase and the water phase, so as to prepare the material feeding for the latter process. The last process is continuous cooling plasticizing and product packaging.

The raw material preparation process of margarine is shown in Figure 1:

- 1. The fermented milk

Some margarine formula to add milk, and milk after lactic acid bacteria fermentation can produce a similar flavor of natural cream, so the factory to fermented milk and water mixed.

- 2. Water mixing

The water and water-soluble additives in the formula of margarine, such as fermented milk, salt, preservatives, etc., are added to the water phase mixing and the metering tank in the prescribed proportion to stir and mix, so that the water phase components are dissolved into a uniform solution.

- 3. Oil phase mixing

The raw oil of different specifications is first mixed in the oil mixing tank according to the prescribed proportion, and then the oil-soluble additives, such as emulsifier, antioxidant, oil-soluble pigment, oil-soluble cellulose, etc., are added to the oil phase according to the proportion, mixed with the metering tank, and stirred to form a uniform oil phase.

- 4. The emulsion

The emulsification purpose of margarine is to make the aqueous phase evenly and stably dispersed in the oil phase, and the dispersion degree of the aqueous phase has a great impact on the quality of the product. Because the flavor of margarine is closely related to the size of the water phase particles, the propagation of microorganisms is carried out in the water phase, the size of the general bacteria is 1-5 microns, so the water droplets in the 10-20 microns or smaller range can limit the propagation of bacteria, so the water phase dispersion is too fine, the water phase particles are too small will make the margarine lose flavor; Dispersing is not sufficient, water phase particle is too large, will make margarine corrupt metamorphism. The relationship between the degree of aqueous phase dispersion in margarine and the nature of the product is roughly as follows:

|

水滴直径 Water drop dimension (微米 micrometer) |

人造奶油性质 (Taste of Margarine) |

|

less than 1 (about 80-85% of water phase) |

Heavy and less taste |

|

30-40 (less than 1% of water phase) |

Good taste, easy to be putrid |

|

1-5 (about 95% of water phase) |

Good taste, not easy to be putrid |

|

5-10 (about 4% of water phase) |

|

|

10-20 (about 1% of water phase) |

It can be seen that emulsification operation should reach a certain degree of dispersion requirements.

The purpose of mixing the water phase and the oil phase separately and evenly with the prior phase is to ensure the uniform consistency of the entire emulsion after the emulsification and mixing of the oil and water two phases. Emulsification mixing is, the operation problem is 50-60 degrees, the water phase is added to the measured oil phase, in the mechanical stirring or pump cycle stirring, is the water phase fully dispersed in the oil phase, the formation of latex. But this kind of latex liquid is very unstable, stop stirring may be on the playground oil and water separation phenomenon.

After the mixed emulsion is delivered, the cooling and plasticizing process is carried out until the product is packaged.

The emulsion must be cooled and plasticized to produce a flexible margarine product. At present, it mainly adopts closed continuous quench plasticizing device, including votator or called scraped surface heat exchanger (unit A), pin rotor machine or kneading machine (unit C) and resting tube (unit B). The technological process is shown in Figure 2:

This set of equipment has the following characteristics:

1. High pressure airtight continuous operation

The premixed emulsion is fed into the quench cylinder by a high pressure pump for votator. High pressure can overcome resistance throughout the unit, in addition to high pressure operation can make the product thin and smooth. Closed operation can prevent air and air due to quenching and condensation of water mixed with the emulsion, ensure the product health requirements, reduce the loss of refrigeration.

2. Quenching and emulsification

The emulsion is quenched with ammonia or Freon in the votator to cool the emulsion rapidly, so that the production of small crystalline particles, generally 1-5 microns, so that the taste is delicate. In addition, the scraper on the rotating shaft in the votator is closely connected with the inner wall of the cylinder, so the scraper in operation can not only continuously scrape the crystallization adhering to the inner wall, but also make the emulsion dispersed to meet the emulsification requirements of the tone.

3. Kneading and dethickening (pin rotor machine)

Although the emulsion cooled by votator has begun to produce crystallization, it still needs to grow through a period of time. If the emulsion is allowed to crystallize at rest, a network of solid lipid crystals will form. The result is that the cooled emulsion will form a very hard mass with no plasticity. Therefore, in order to obtain margarine products with certain plasticity, the network structure must be broken by mechanical means before the emulsion forms the overall network structure, so as to achieve the effect of reducing thickening. Kneading and de-thickening is mainly performed in pin rotor machine.

Unit A (votator) is actually a scraper cooling device. The emulsion is driven into the closed unit A (votator) by high-pressure pump. The material passes through the channel between the cooling cylinder and the rotating shaft, and the material temperature drops rapidly by the quenching of the cooling medium. Two rows of scrapers are arranged on the surface of the shaft. The crystals formed on the inner surface of the votator are scraped away by the high-speed rotating scraper to always expose the new cooling surface and maintain efficient heat transfer. The emulsion can be dispersed under the action of the scraper. When the material passes through unit A (votator), the temperature drops to 10-20 degrees, which is lower than the melting point of the oil. Although the oil begins to crystallize, it has not yet formed a solid state. At this time, the emulsion is in the state of cooling and it is a thick liquid.

The rotation axis of unit A (votator) is hollow. During operation, hot water of 50-60 degrees is poured into the center of the rotation axis to prevent crystallization bonded and cured on the axis and cause blockage.

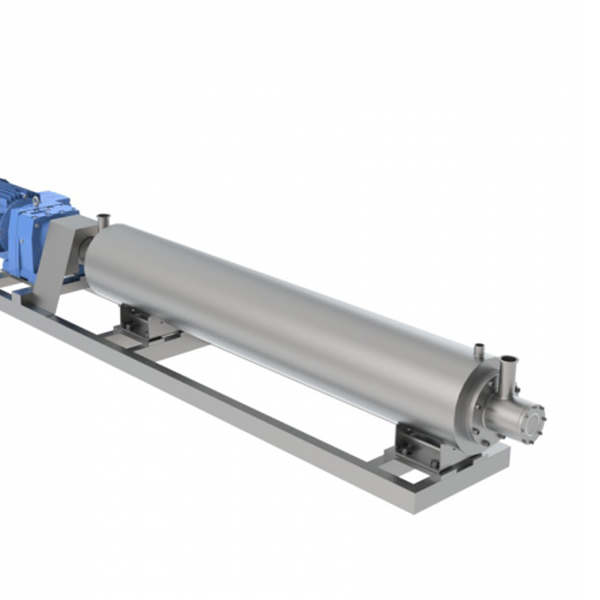

Unit C (pin rotor machine) is kneading and de-thickening device, as shown in the figure above. Two rows of metal bolts are installed on the rotating shaft, and a row of fixed metal bolts are installed on the inner wall of the cylinder, which are staggered with the metal bolts on the shaft and do not touch each other. When the shaft rotates at a high speed, the metal bolts on the shaft pass the gap of the fixed metal bolts, and the material is fully kneaded. Under this action, it can promote the growth of crystals, destroy the crystal network structure, form discontinuous crystals, reduce the consistency, and increase the plasticity.

Unit C (pin rotor machine) only plays a strong kneading effect on the super cold night, so it only needs heat preservation and does not need cooling. As the crystallization heat is released (about 50KCAL/KG), and the heat generated by kneading friction, the discharge temperature of unit C (pin rotor macjhine) is higher than that of the feed temperature. At this time, the crystallization is about 70% complete, but it is still soft. The final product is released through the extrusion valve, and it will become hard after a certain time.

After the margarine is sent from the C unit (pin rotor machine), it needs to be heat treated at a certain temperature. Generally, the product is placed at a temperature of 10 degrees below the melting point for more than 48 hours. This treatment is called ripening. The cooked product can be sent directly to the food processing plant for use.

Product detail pictures:

Related Product Guide:

Being supported by an advanced and professional IT team, we could offer technical support on pre-sales & after-sales service for High Quality Dma Recovery Plant - Sheet margarine packaging line – Shipu Machinery , The product will supply to all over the world, such as: Dominica, Uruguay, Jamaica, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to offer skilled, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We are going to serve you with all sincerity!

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.