High Quality for Dry Chemical Powder Packing Machine - Completed Milk Powder Can Filling & Seaming Line China Manufacturer – Shipu Machinery

High Quality for Dry Chemical Powder Packing Machine - Completed Milk Powder Can Filling & Seaming Line China Manufacturer – Shipu Machinery Detail:

Different packaging materials & machines

This point is obvious from the appearance. The canned milk powder mainly uses two materials, metal, and environmentally friendly paper. The moisture resistance and pressure resistance of the metal are the first choices. Although the environmentally friendly paper is not as strong as the iron can, it is convenient for consumers. It is also stronger than ordinary carton packaging. The outer layer of the boxed milk powder is usually a thin paper shell, and the inner layer is a plastic package (bag). The sealing and moisture resistance of the plastic is not as good as the metal can.

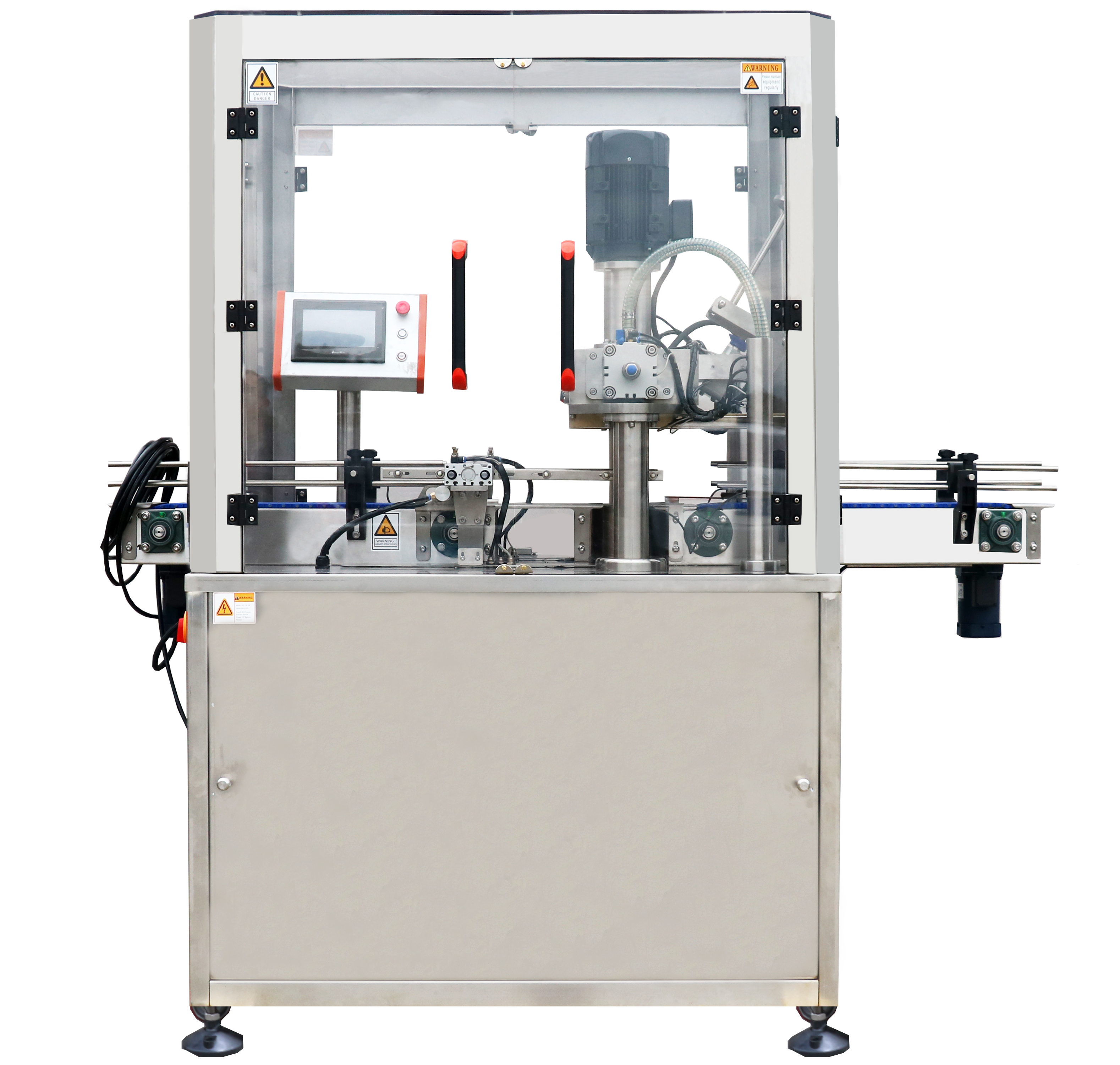

In additional, the processing machine is obviously different. The canned milk powder is packed by completed can filling & seaming line, including can feeding, can sterilization tunnel, can filling machine, vacuum can seamer and etc. While the main machine for plastic package is only powder packaging machine. The equipment investment is also much different.

The capacity is different

The typical can’s capacity in the milk markets is about 900 grams (or 800g, 1000g), while the boxed milk powder is generally 400g, some boxed milk powder is 1200g, there are 3 small bags of 400g small package, there are also 800 grams, 600 grams, etc.

Different shelf life

If you pay attention to the shelf life of milk powder, you will find that canned milk powder and boxed milk powder are very different. Generally, the shelf life of canned milk powder is 2 to 3 years, while boxed milk powder is generally 18 months. This is because canned milk powder’s sealing is better and it is beneficial to the preservation of milk powder so it is not easy to spoil and deteriorate, and it is easier to seal after opening.

Sktech map

Product detail pictures:

Related Product Guide:

We'll make each hard work to become excellent and excellent, and speed up our measures for standing from the rank of intercontinental top-grade and high-tech enterprises for High Quality for Dry Chemical Powder Packing Machine - Completed Milk Powder Can Filling & Seaming Line China Manufacturer – Shipu Machinery , The product will supply to all over the world, such as: panama, Algeria, Tunisia, Nowadays our products sell all over the domestic and abroad thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!