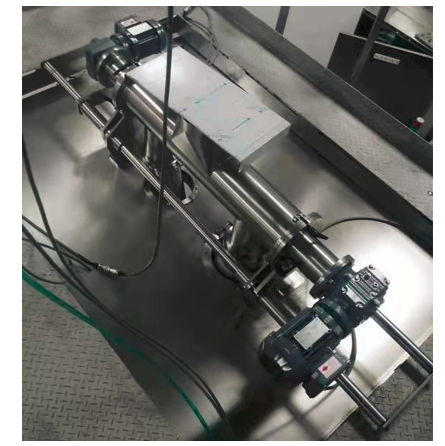

Horizontal Screw Conveyor

Horizontal Screw Conveyor Detail:

Technical Specification

| Model |

SP-H1-5K |

| Transfer speed |

5 m3/h |

| Transfer pipe diameter |

Φ140 |

| Total Powder |

0.75KW |

| Total Weight |

80kg |

| Pipe thickness |

2.0mm |

| Spiral outer diameter |

Φ126mm |

| Pitch |

100mm |

| Blade thickness |

2.5mm |

| Shaft diameter |

Φ42mm |

| Shaft thickness |

3mm |

Length: 600mm (center of inlet and outlet)

pull-out, linear slider

The screw is fully welded and polished, and the screw holes are all blind holes

SEW geared motor, power 0.75kw, reduction ratio 1:10

Product detail pictures:

Related Product Guide:

With our loaded working experience and thoughtful products and services, we've got been acknowledged as a reputable supplier for most international buyers for Horizontal Screw Conveyor , The product will supply to all over the world, such as: New Delhi, Guinea, Roman, Many kinds of different products are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products with us!!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.

Write your message here and send it to us