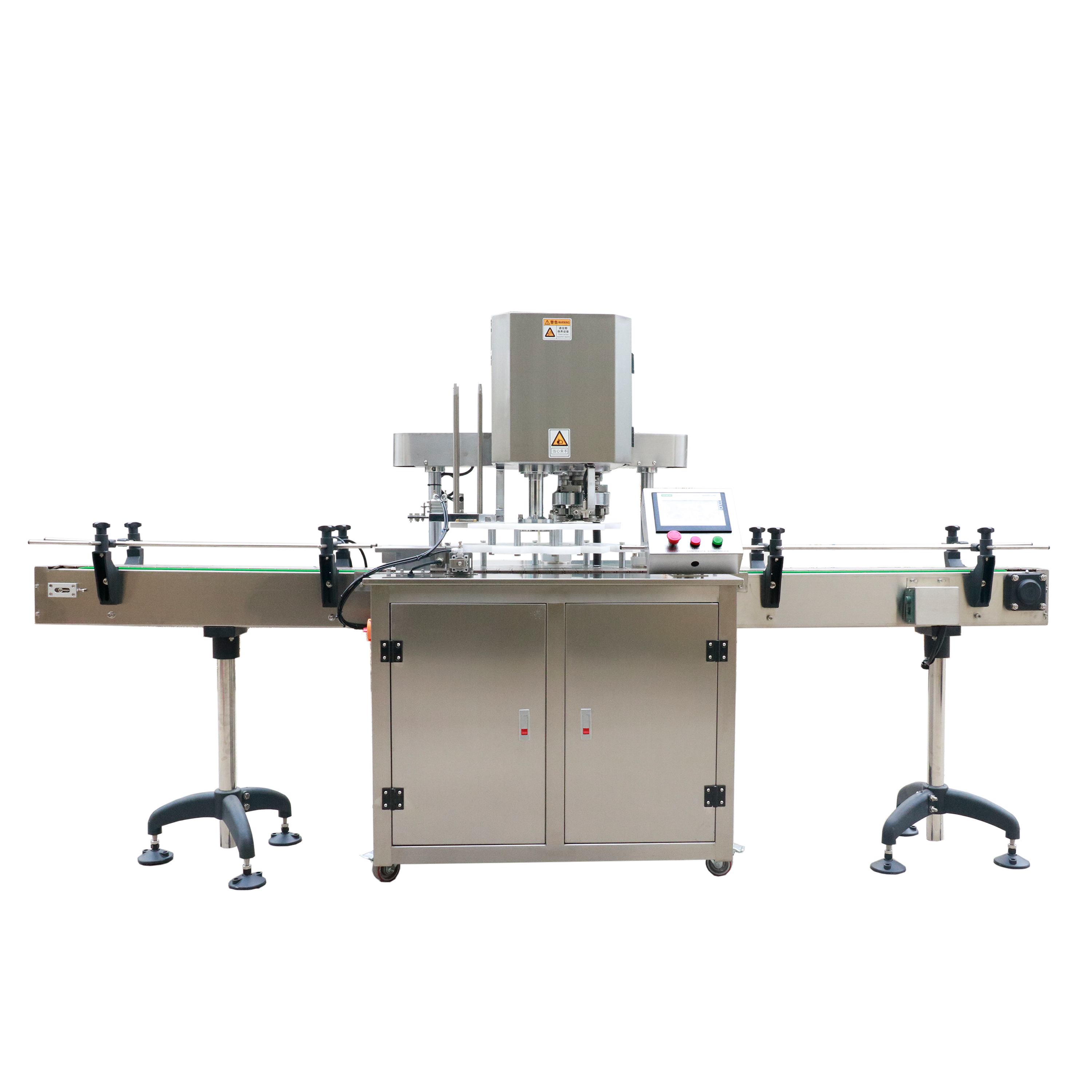

Hot Sale for Talcum Powder Filling Machine - SPAS-100 Automatic Can Seaming Machine – Shipu Machinery

Hot Sale for Talcum Powder Filling Machine - SPAS-100 Automatic Can Seaming Machine – Shipu Machinery Detail:

There are two model of this automatic can seaming machine, one is standard type, without dust protection, the can seaming speed is fixed; the other one is high speed type, with dust protection, speed is adjustable by frequency inverter.

Performance characteristics

With two pairs (four) of seaming rolls, the cans are stationary without rotating while the can seaming rolls rotate at high speed during seaming;

Different-sized ring-pull cans can be seamed by replacing accessories like lid-pressing die, can clamp disc and lid-dropping device;

The machine is highly automatic and easily operated with VVVF, PLC control and human- machine interface touch panel;

Can-lid interlock control: corresponding lid is given only when there is a can, and no lid no can;

The can seaming machine will stop in the case of no lid: it can automatically stop when no lid is dropped by the lid-dropping device so as to avoid seizing of lid-pressing die by the can and parts damage of seaming mechanism;

The seaming mechanism is driven by synchronous belt, which allows simple maintenance and low noise;

The continuously-variable conveyor is simple in structure and easy to operate and maintain;

The outer housing and main parts are made of 304 stainless steel to meet hygienic requirements of food and drugs.

Technical Parameters

|

Production capacity |

Standard: 35 cans/min.(fixed speed) |

|

High speed: 30-50 cans/min (speed adjustable by frequency inverter) |

|

|

Applicable range |

Can diameter: φ52.5-φ100mm ,φ83-φ127mm Can height: 60-190mm (Special specifications can be customized.) |

|

Voltage |

3P/380V/50Hz |

|

Power |

1.5kw |

|

Total Weight |

500kg |

|

Overall dimensions |

1900(L)×710(W)×1500(H)mm |

|

Overall dimensions |

1900(L)×710(W)×1700(H)mm ( Framed) |

|

Working pressure (compressed air) |

≥0.4Mpa About 100L/min |

Equipment details

Product detail pictures:

Related Product Guide:

Persisting in "High high quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with clients from the two overseas and domestically and get new and old clients' superior comments for Hot Sale for Talcum Powder Filling Machine - SPAS-100 Automatic Can Seaming Machine – Shipu Machinery , The product will supply to all over the world, such as: Turkey, Luxembourg, Mexico, If any item be of interest to you, you should let us know. We will try our best to satisfy your requirements with high quality goods, the best prices and prompt delivery. You should feel free to contact us at any time. We will reply you when we receive your inquiries. Make sure you note that samples are available before we start our business.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.