Metal Detector

Metal Detector Detail:

Basic Information of Metal Separator

1) Detection and separation of magnetic and non-magnetic metal impurities

2) Appropriate for powder and fine-grained bulk material

3) Metal separation using a reject flap system (“Quick Flap System”)

4) Hygienic design for easy cleaning

5) Meets all IFS and HACCP requirements

6) Complete Documentation

7) Outstanding ease of operation with product auto-learn function and latest microprocessor technology

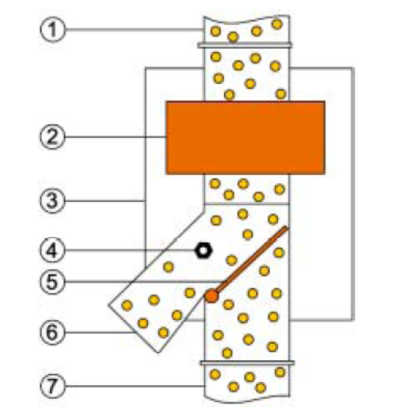

II.Working Principle

① Inlet

② Scanning Coil

③ Control Unit

④ Metal impurity

⑤ Flap

⑥ Impurity Outlet

⑦ Product Outlet

Product falls through the scanning coil ②, when metal impurity④ is detected, the flap ⑤is activated and metal ④ is ejected from impurity outlet⑥.

III.Feature of RAPID 5000/120 GO

1) Diameter of the Pipe of Metal Separator: 120mm; Max. Throughput: 16,000 l/h

2) Parts in touch with material: stainless steel 1.4301(AISI 304), PP pipe, NBR

3) Sensitivity adjustable: Yes

4) Drop height of bulk material : Free fall, maximum 500mm above equipment top edge

5) Max Sensitivity: φ 0.6 mm Fe ball, φ 0.9 mm SS ball and φ 0.6 mm Non-Fe ball(without consideration of product effect and ambient disturbance)

6) Auto-learn function: Yes

7) Type of protection: IP65

8) Reject duration: from 0.05 to 60 sec

9) Compression air: 5 - 8 bar

10) Genius One control unit: clear and fast to operate on 5“ touchscreen, 300 product memory, 1500 event record, digital processing

11) Product tracking: automatically compensate slow variation of product effects

12) Power supply: 100 - 240 VAC (±10%), 50/60 Hz, single phase. Current consumption: approx. 800 mA/115V , approx. 400 mA/230 V

13) Electrical connection:

Input:

“reset” connection for possibility of an external reset button

Output:

2 potential-free relay switchover contact for external “metal” indication

1 potential- free relay switchover contact for external “error” indication

Product detail pictures:

Related Product Guide:

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for Metal Detector , The product will supply to all over the world, such as: Netherlands, Jersey, Islamabad, With more and more Chinese products and solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to supply you both better solutions and service, because we've been more and more powerful, specialist and experience in domestic and international.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!