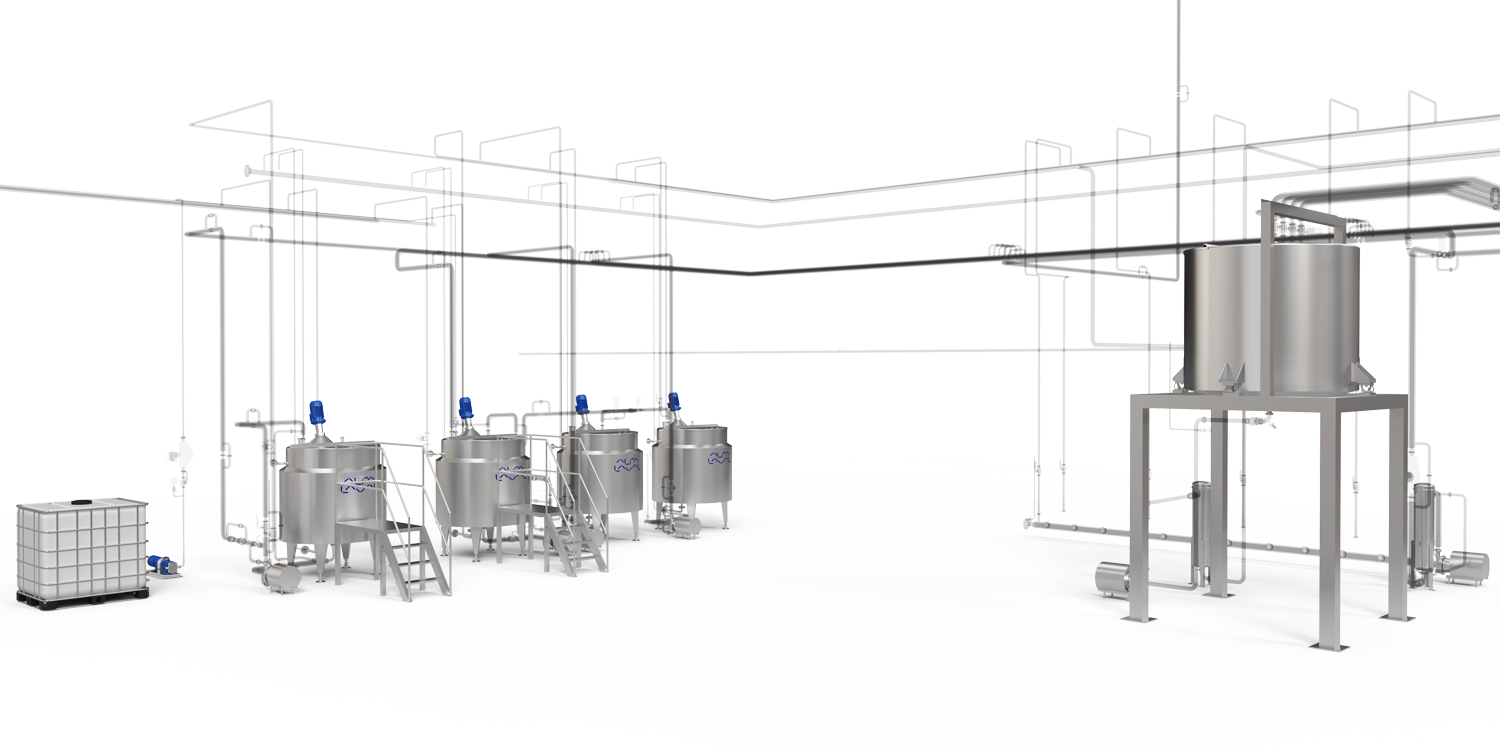

The margarine production process consists of five sections: the oil phase with emulsifier preparation, the water phase, the emulsion preparation, pasteurization, crystallization and packaging. Any excess production is returned via a continuous rework unit to the emulsion tank.

Oil phase and emulsifier preparation in margarine production

A pump transfers oil, fat or blended oil from storage tanks through a filter to a weighting system. To obtain the correct oil weight, this tank is installed above load cells. The blend oil is mixed according to a recipe.

Emulsifier preparation is accomplished by mixing oil with the emulsifier. Once the oil reaches a temperature of approximately 70°C, the emulsifiers such as lecithin, monoglycerides and diglycerides, usually in powder form, are manually added into the emulsifier tank. Other oil-soluble ingredients such as colouring and flavour may be added.

Water phase in margarine production

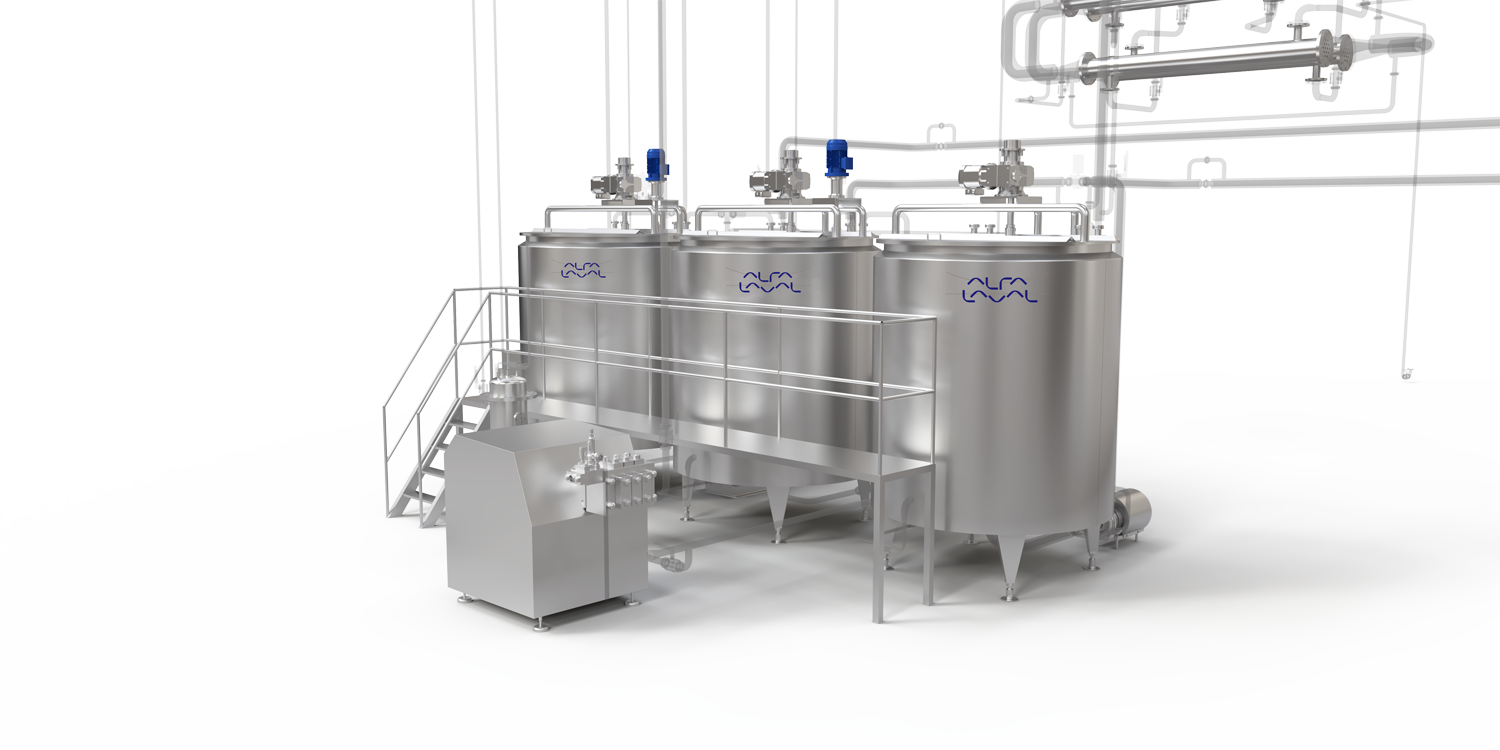

Insulated tanks are supplied for the production of the water phase. A flow meter doses the water into the tank where it is heated to a temperature above 45ºC. Dry ingredients such as salt, citric acid, hydrocolloids or skimmed milk powder may be added into the tank using special equipment such as a powder funnel mixer.

Emulsion preparation in margarine production

The emulsion is prepared by dosing oils and fats with the emulsifier blend and the water phase in the said order. Mixing of the oil phase and water phase takes place in the emulsion tank. Here, other ingredients, such as flavour, aroma and colourant, may be added manually. A pump transfers the resulting emulsion to the feed tank.

Special equipment, such as a high shear mixer, may be used at this stage of the process to make the emulsion very fine, narrow and tight, and to ensure good contact between the oil phase and the water phase. The resulting fine emulsion will create a high-quality margarine that exhibits good plasticity, consistency and structure.

A pump then forwards the emulsion to the pasteurization area.

Crystallization in margarine production

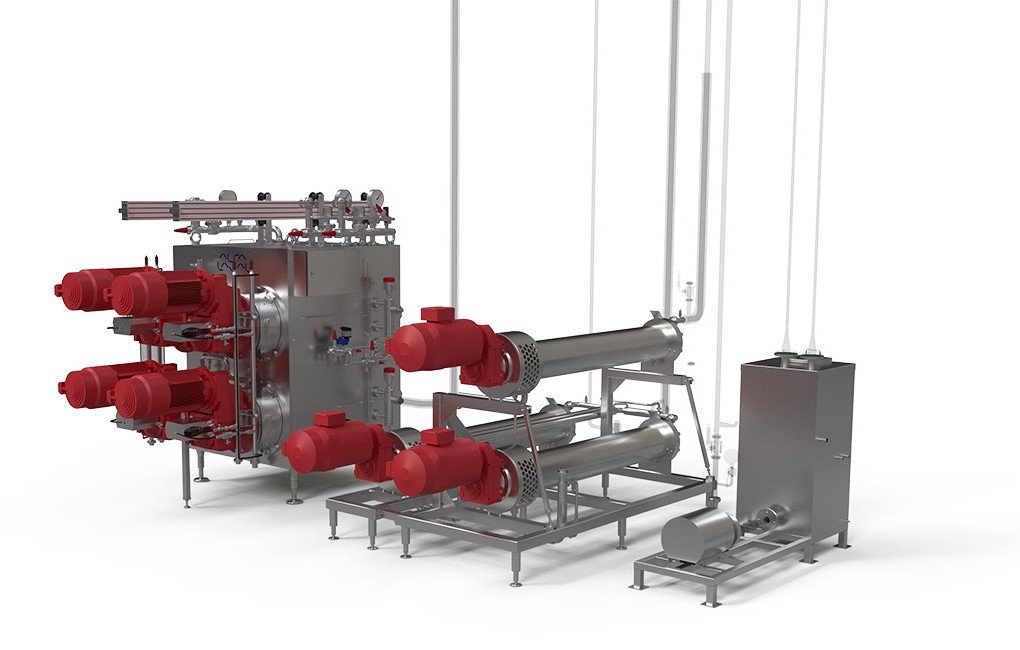

A high-pressure pump transfers the emulsion to a high-pressure scraped surface heat exchanger (SSHE), which is configured according to the flow rate and recipe. There may be various cooling tubes of different sizes and different cooling surfaces. Each cylinder has an independent cooling system into which the refrigerant (typically ammonia R717 or Freon) is directly injected. Product pipes connect each cylinder to one another. Temperature sensors at each outlet ensure proper cooling. The maximum pressure rating is 120 bar.

Depending on the recipe and application, the emulsion may need to pass through one or more pin worker units prior to packing. Pin worker units ensure the proper plasticity, consistency and structure of the product. If required, Alfa Laval can supply a resting tube; however, most packing machine suppliers provide one.

Continuous rework unit

A continuous rework unit is designed to re-melt all excess product that by-passed the packing machine for reprocessing. At the same time, it keeps the packing machine free of any undesired backpressure. This complete system consists of a plate heat exchanger, tempered recirculating water pump, and water heater.

Post time: Jun-21-2022