OEM Factory for Chips Packing Machine With Nitrogen - Automatic Liquid Packaging Machine Model SPLP-7300GY/GZ/1100GY – Shipu Machinery

OEM Factory for Chips Packing Machine With Nitrogen - Automatic Liquid Packaging Machine Model SPLP-7300GY/GZ/1100GY – Shipu Machinery Detail:

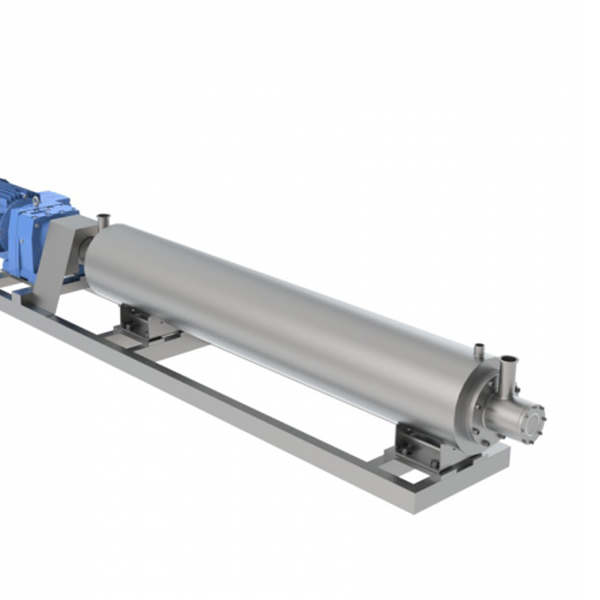

Equipment description

This unit is developed for the need of metering and filling of high viscosity media. It is equipped with servo rotor metering pump for metering with the function of automatic material lifting and feeding, automatic metering and filling and automatic bag-making and packaging, and is also equipped with the memory function of 100 product specifications, the switchover of weight specification can be realized just by one-key stroke.

Application

Suitable materials: Tomato paste packaging, chocolate packaging, shortening/ghee packaging, honey packaging, sauce packaging and etc.

Technical Spec.

|

Model |

Bag size mm |

Metering range |

Measuring accuracy |

Packaging speed bags/min |

|

SPLP7300GY |

(150~500)*(100~350) |

100-5000g |

≤0.5% |

8~25 |

|

SPLP 7300GZ |

(150~500)*(100~350) |

100-5000g |

≤0.5% |

8-15 |

|

SPLP 1100GY |

(200~1000)*(350~750) |

0.5-25kg |

≤0.5% |

3-8 |

Product detail pictures:

Related Product Guide:

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for OEM Factory for Chips Packing Machine With Nitrogen - Automatic Liquid Packaging Machine Model SPLP-7300GY/GZ/1100GY – Shipu Machinery , The product will supply to all over the world, such as: Georgia, Belgium, Indonesia, We always insist on the management tenet of "Quality is first, Technology is basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,