OEM Factory for Chips Packing Machine With Nitrogen - Powder Detergent Packaging Unit Model SPGP-5000D/5000B/7300B/1100 – Shipu Machinery

OEM Factory for Chips Packing Machine With Nitrogen - Powder Detergent Packaging Unit Model SPGP-5000D/5000B/7300B/1100 – Shipu Machinery Detail:

Application

Cornflakes packaging, candy packaging, puffed food packaging, chips packaging, nut packaging, seed packaging, rice packaging, bean packaging baby food packaging and etc. Especially suitable for easily broken material.

The unit consists of a SPGP7300 vertical filling packaging machine, a combination scale (or SPFB2000 weighing machine) and vertical bucket elevator, integrates the functions of weighing, bag-making, edge-folding, filling, sealing, printing, punching and counting, adopts servo motor driven timing belts for film pulling. All the control components adopt international famous brand products with reliable performance. Both transverse and longitudinal sealing mechanism adopt pneumatic system with stable and reliable action. Advanced design ensures that adjustment, operation and maintenance of this machine are very convenient.

Main technical data

| Model |

Bag sizemm |

Metering range | Measuring accuracy | Packaging speedbags/min |

| SPGP-5000D | (50~280)×(70~180) | 0.2% | ||

| SPGP-5000B | (50~340)×(80~250) | 10~2000g | 10~50 | |

| SPGP-7300B | (50~460)×(80~350) | 200~5000 g | 10~50 | |

| SPGP-1100 | (300-650)x(300-500) | 0.5~10kg | 5~10 | |

| SPGP-1500 | (200~1000)×(350~750) | 1~25kg | 3~8 | |

| SPGP-1700 | (200~1000)×(500~850) | 1~50kg | 2~5 |

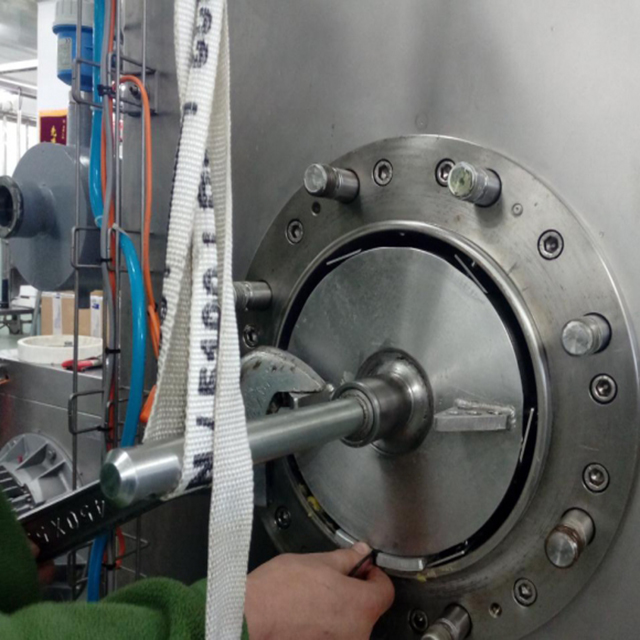

Product detail pictures:

Related Product Guide:

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for OEM Factory for Chips Packing Machine With Nitrogen - Powder Detergent Packaging Unit Model SPGP-5000D/5000B/7300B/1100 – Shipu Machinery , The product will supply to all over the world, such as: Florence, Finland, Sydney, Why we can do these? Because: A, We are honest and reliable. Our items have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It might be highly appreciated.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.