Powder Detergent Packaging Unit Model SPGP-5000D/5000B/7300B/1100

Powder Detergent Packaging Unit Model SPGP-5000D/5000B/7300B/1100 Detail:

Equipment Description

The powder detergent bag packaging machine consists of a vertical bag packaging machine, SPFB2000 weighing machine and vertical bucket elevator, integrates the functions of weighing, bag-making, edge-folding, filling, sealing, printing, punching and counting, adopts servo motor driven timing belts for film pulling. All the control components adopt international famous brand products with reliable performance. Both transverse and longitudinal sealing mechanism adopt pneumatic system with stable and reliable action. Advanced design ensures that adjustment, operation and maintenance of this machine are very convenient.

Technical Specification

| Model | SPGP-420 | SPGP-520 | SPGP-720 |

| Film width | 140~420mm | 140~520mm | 140~720mm |

| Bag width | 60~200mm | 60~250mm | 60~350mm |

| Bag length | 50~250mm, single film pulling | 50~250mm, single film pulling | 50~250mm, single film pulling |

| Filling range*1 | 10~750g | 10~1000g | 50~2000g |

| Packing Speed*2 | 20~40bpm on PP | 20~40bpm on PP | 20~40bpm on PP |

| Install Voltage | AC 1phase, 50Hz, 220V | AC 1phase, 50Hz, 220V | AC 1phase, 50Hz, 220V |

| Total Power | 3.5KW | 4KW | 5.5KW |

| Air Consumption | 2CFM @6 bar | 2CFM @6 bar | 2CFM @6 bar |

| Dimensions*3 | 1300x1240x1150mm | 1300x1300x1150mm | 1300x1400x1150mm |

| Weight | Approx. 500kg | Approx. 600 kg | Approx. 800 kg |

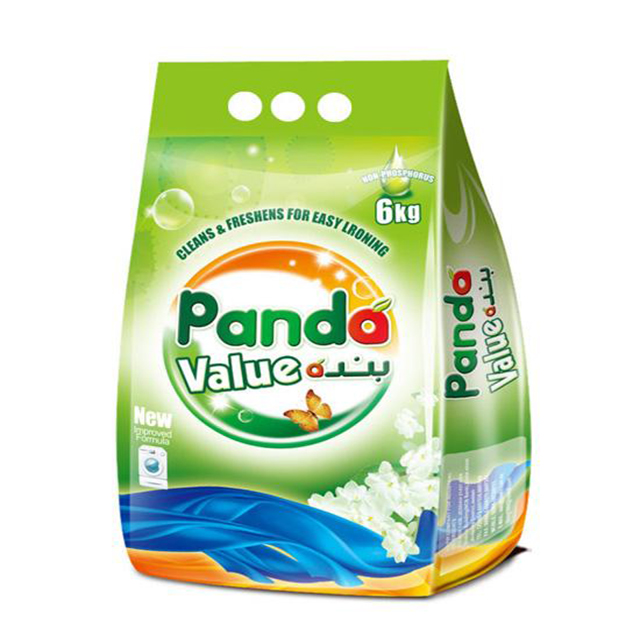

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Powder Detergent Packaging Unit Model SPGP-5000D/5000B/7300B/1100 , The product will supply to all over the world, such as: Curacao, Benin, British, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

Write your message here and send it to us