PriceList for Nitrogen Packing Machine For Snacks - Multi Lane Sachet Packaging Machine Model: SPML-240F – Shipu Machinery

PriceList for Nitrogen Packing Machine For Snacks - Multi Lane Sachet Packaging Machine Model: SPML-240F – Shipu Machinery Detail:

Main feature

- Omron PLC controller with touch screen interface.

- Panasonic/Mitsubishi servo-driven for film pulling system.

- Pneumatic driven for horizontal end sealing.

- Omron temperature control table.

- Electric Parts use Schneider/LS brand.

- Pneumatic components use SMC brand.

- Autonics brand Eye mark sensor for controlling the packing bag length size.

- Die-cut style for round corner, with high firmness and slice the side smooth.

- Alarm function: Temperature

- No film run automatic alarming.

- Safety warning labels.

- Door protection device and interaction with PLC control.

Main function

- Empty bag preventive device;

- Printing mode matching: Photoelectric sensor detect;

- Dosing synchronous sending signal 1:1;

- Bag length adjustable mode: Servo motor;

Machine automatic stop function:

- Packing film end

- Printing band end

- Heater error

- Air pressure low

- Band printer

- Film pulling motor, Mitsubishi: 400W, 4 units/set

- Film output, CPG 200W, 4 units/set

- HMI: Omron, 2 units/set

- The configuration could be optional as per customer’s requirements.

Main technical data

|

Dosing mode |

Auger filler |

|

Bag Type |

stick bag, sachet, pillow bag,3 side sachet,4 side sachet |

|

Bag Size |

L:55-180mm W:25-110mm |

|

Film Width |

60-240mm |

|

Filling Weight |

0.5-50g |

|

Packaging Speed |

110-280 bags/min |

|

Packaging Accuracy |

0.5 – 10g, ≤±3-5%;10 – 50g, ≤±1-2% |

|

Power Supply |

3P AC208-415V 50/60Hz |

|

Total Power |

15.8kw |

|

Total Weight |

1600kg |

|

Air Supply |

6kg/m2 , 0.8m3/min |

|

Overall Dimension |

3084×1362×2417mm |

|

Hopper Volume |

25L |

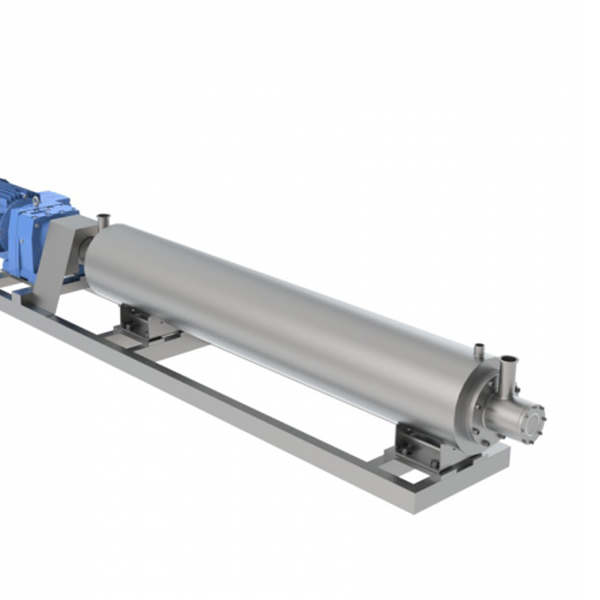

Equipment details

Product detail pictures:

Related Product Guide:

We have state-of-the-art tools. Our products are exported towards the USA, the UK and so on, enjoying a fantastic reputation amongst customers for PriceList for Nitrogen Packing Machine For Snacks - Multi Lane Sachet Packaging Machine Model: SPML-240F – Shipu Machinery , The product will supply to all over the world, such as: United Kingdom, Saudi Arabia, Sao Paulo, It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we'll be happy to serve you.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!

Write your message here and send it to us