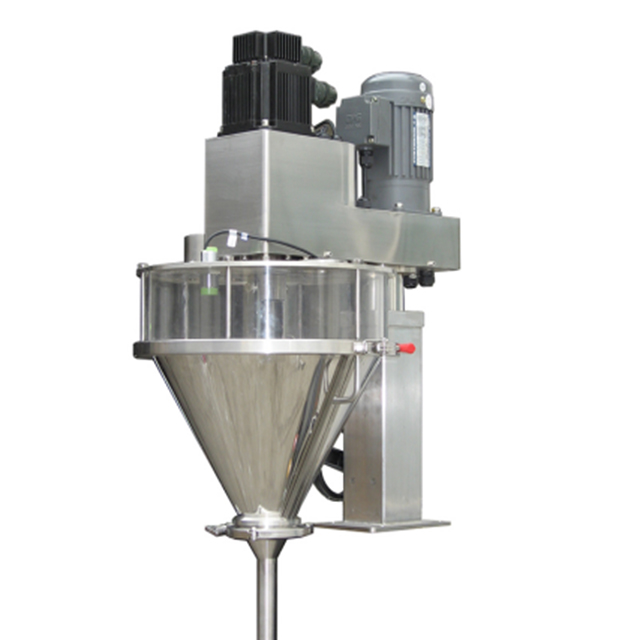

Rapid Delivery for Peanut Butter Packing Machine - Semi-auto Auger filling machine with online weigher Model SPS-W100 – Shipu Machinery

Rapid Delivery for Peanut Butter Packing Machine - Semi-auto Auger filling machine with online weigher Model SPS-W100 – Shipu Machinery Detail:

Main features

Stainless steel structure; Quick disconnecting hopper could be washed easily without tools.

Servo motor drive screw.

Weight feedback and proportion track get rid of the shortage of variable packaged weight for various proportion of different material.

Save the parameter of different filling weight for different materials. To save 10 sets at most

Replacing the auger parts, it is suitable for material from super thin powder to granule.

Main Technical Data

|

Can Packing Weight |

1kg – 25kg |

|

Can Packing Accuracy |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

|

Can Packing Speed |

22 – 8 times per min |

|

Power Supply |

3P AC208 – 415V 50/60Hz |

|

Compressed air |

6kg/cm3 0.1cbm/min |

|

Total Power |

2.37Kw |

|

Total Weight |

350kg |

|

Overall Dimension |

1125×975×2500mm |

|

Hopper Volume |

100L |

Configuration

|

No |

Name |

Model Specification |

PRODUCING AREA, Brand |

|

1 |

Stainless steel | SUS304 |

China |

|

2 |

PLC | Taiwan Fatek | |

|

3 |

HMI | Schneider | |

|

4 |

Filling Servo motor | TSB13152B-3NTA-1 | Taiwan TECO |

|

5 |

Filling Servo driver | ESDA40C | Taiwan TECO |

|

6 |

Agitator motor | GV-28 0.4kw,1:30 | Taiwan Yu Sin |

|

7 |

Electromagnetic valve | Taiwan SHAKO | |

|

8 |

Cylinder | MA32X150-S-CA | Taiwan Airtac |

|

9 |

Air Filter and booster | AFR-2000 | Taiwan Airtac |

|

10 |

Switch | HZ5BGS | Wenzhou Cansen |

|

11 |

Circuit breaker | Schneider | |

|

12 |

Emergency switch |

Schneider | |

|

13 |

EMI Filter | ZYH-EB-10A | Beijing ZYH |

|

14 |

Contactor | CJX2 1210 | Wenzhou CHINT |

|

15 |

Heat relay | NR2-25 | Wenzhou CHINT |

|

16 |

Relay | MY2NJ 24DC |

Japan Omron |

|

17 |

Switching power supply | Changzhou Chenglian | |

|

18 |

AD Weighing Module | MAINFILL | |

|

19 |

Loadcell | IL-150 | Mettler Toledo |

|

20 |

Photo sensor | BR100-DDT | Korea Autonics |

|

21 |

Level sensor | CR30-15DN | Korea Autonics |

Product detail pictures:

Related Product Guide:

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Rapid Delivery for Peanut Butter Packing Machine - Semi-auto Auger filling machine with online weigher Model SPS-W100 – Shipu Machinery , The product will supply to all over the world, such as: Nicaragua, Auckland, Algeria, Our solutions have national accreditation standards for experienced, premium quality goods, affordable value, was welcomed by people around the globe. Our products will continue to increase in the order and look forward to cooperation with you, Truly must any of people goods be of interest to you, make sure you letus know. We're likely to be delighted to give you a quotation up on receipt of one's in depth specs.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!