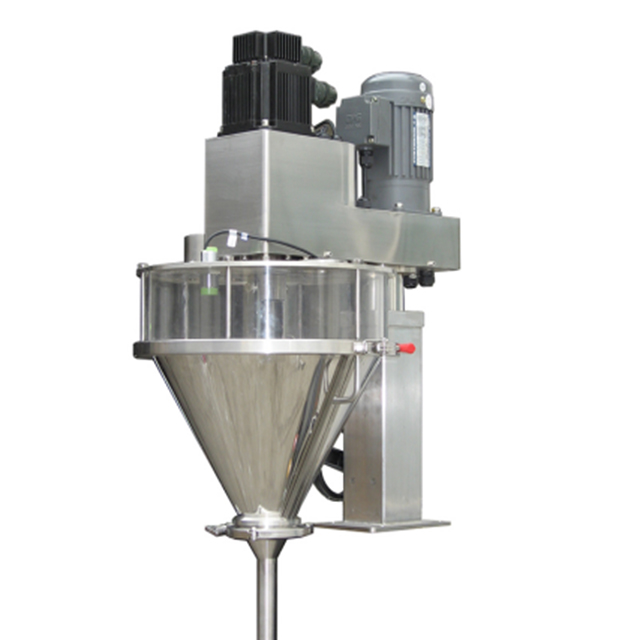

Semi-auto Auger filling machine with online weigher Model SPS-W100

Semi-auto Auger filling machine with online weigher Model SPS-W100 Detail:

Main features

Stainless steel structure; Quick disconnecting or split hopper could be washed easily without tools.

Servo motor drive screw.

Pneumatic bag clamper and platform equip with load cell to handle two speeds filling as per preset weight.Featured with high speed and accuracy weighing system.

PLC control, touch screen display, easy to operate.

Two filling modes can be inter-changeable, fill by volume or fill by weight. Fill by volume featured with high speed but low accuracy. Fill by weight featured with high accuracy but low speed.

Save the parameter of different filling weight for different materials. To save 10 sets at most.

Replacing the auger parts, it is suitable for material from super thin powder to granule.

Technical Specification

| Model | SPW-B50 | SPW-B100 |

| Filling Weight | 100g-10kg | 1-25kg |

| Filling Accuracy | 100-1000g, ≤±2g; ≥1000g, ≤±0.1-0.2%; | 1-20kg, ≤±0.1-0.2%; ≥20kg, ≤±0.05-0.1%; |

| Filling Speed | 3-8 times/min. | 1.5-3 times/min. |

| Power Supply | 3P AC208-415V 50/60Hz | 3P, AC208-415V, 50/60Hz |

| Total Power | 2.65kw | 3.62kw |

| Total Weight | 350kg | 500kg |

| Overall Dimension | 1135×890×2500mm | 1125x978x3230mm |

| Hopper Volume | 50L | 100L |

Configuration

|

No |

Name |

Model Specification |

PRODUCING AREA, Brand |

|

1 |

Stainless steel | SUS304 |

China |

|

2 |

PLC |

|

Taiwan Fatek |

|

3 |

HMI |

|

Schneider |

|

4 |

Filling Servo motor | TSB13152B-3NTA-1 | Taiwan TECO |

|

5 |

Filling Servo driver | ESDA40C | Taiwan TECO |

|

6 |

Agitator motor | GV-28 0.4kw,1:30 | Taiwan Yu Sin |

|

7 |

Electromagnetic valve |

|

Taiwan SHAKO |

|

8 |

Cylinder | MA32X150-S-CA | Taiwan Airtac |

|

9 |

Air Filter and booster | AFR-2000 | Taiwan Airtac |

|

10 |

Switch | HZ5BGS | Wenzhou Cansen |

|

11 |

Circuit breaker |

|

Schneider |

|

12 |

Emergency switch |

|

Schneider |

|

13 |

EMI Filter | ZYH-EB-10A | Beijing ZYH |

|

14 |

Contactor | CJX2 1210 | Wenzhou CHINT |

|

15 |

Heat relay | NR2-25 | Wenzhou CHINT |

|

16 |

Relay | MY2NJ 24DC |

Japan Omron |

|

17 |

Switching power supply |

|

Changzhou Chenglian |

|

18 |

AD Weighing Module |

|

MAINFILL |

|

19 |

Loadcell | IL-150 | Mettler Toledo |

|

20 |

Photo sensor | BR100-DDT | Korea Autonics |

|

21 |

Level sensor | CR30-15DN | Korea Autonics |

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Semi-auto Auger filling machine with online weigher Model SPS-W100 , The product will supply to all over the world, such as: Iraq, St. Petersburg, Bolivia, We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We will always believe in and work on it. Welcome to join us to promote green light, together we will make a better Future!

Problems can be quickly and effectively resolved, it is worth to be trust and working together.