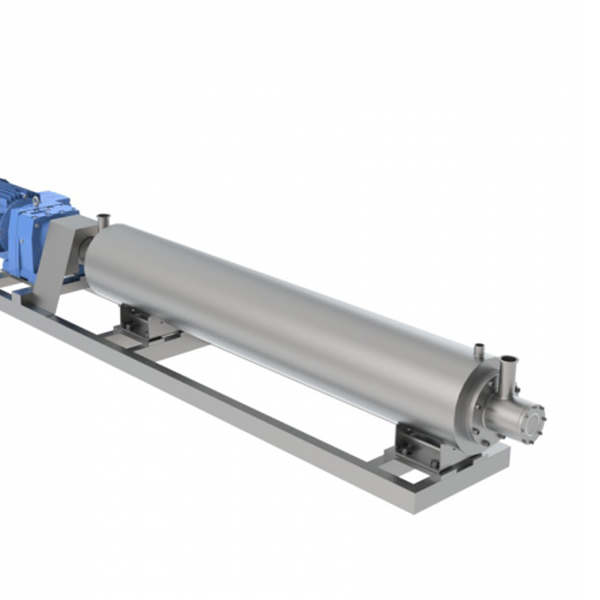

Short Lead Time for Powder Filling And Sealing Machine - Automatic Powder Bottle Filling Machine Model SPCF-R1-D160 – Shipu Machinery

Short Lead Time for Powder Filling And Sealing Machine - Automatic Powder Bottle Filling Machine Model SPCF-R1-D160 – Shipu Machinery Detail:

Main features

Stainless steel structure, level split hopper, easily to wash.

Servo-motor drive auger. Servo-motor controlled turntable with stable performance.

PLC, touch screen and weighing module control.

With adjustable height-adjustment hand-wheel at reasonable height, easy to adjust the head position.

With pneumatic bottle lifting device to assure the material not spilling out when filling.

Weight-chosen device, to assure each product be qualified, so to leave the latter cull eliminator.

To save all product’s parameter formula for later use, save 10 sets at most.

When changing the auger accessories, it is suitable for materials ranging from super fine powder to small granule

Main technical data

|

Bottle Size |

φ30-160mm , H50-260mm |

|

Filling Weight |

10 – 5000g |

|

Filling Accuracy |

≤ 500g, ≤±1%; >500g, ≤±0.5% |

|

Filling Speed |

20 – 40 bottles/min |

|

Power Supply |

3P AC208-415V 50/60Hz |

|

Air Supply |

6 kg/cm2 0.05m3/min |

|

Total Power |

2.3Kw |

|

Total Weight |

350kg |

|

Overall Dimensions |

1840×1070×2420mm |

|

Hopper Volume |

50L(Enlarged Size 65L) |

Equipment details

Product detail pictures:

Related Product Guide:

Trustworthy good quality and excellent credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality first, buyer supreme" for Short Lead Time for Powder Filling And Sealing Machine - Automatic Powder Bottle Filling Machine Model SPCF-R1-D160 – Shipu Machinery , The product will supply to all over the world, such as: Rio de Janeiro, Amman, Slovenia, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in public placesand other industries. Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!