Vacuum Feeder Model ZKS

Vacuum Feeder Model ZKS Detail:

Main features

ZKS vacuum feeder unit is using whirlpool air pump extracting air. The inlet of absorption material tap and whole system is made to be in vacuum state. The powder grains of material are absorbed into the material tap with ambient air and formed to be the air flowing with material. Passing the absorption material tube, they arrive to the hopper. The air and materials are separated in it. The separated materials are sent to the receiving material device. The control center controls the “on/off” state of pneumatic triple valve for feeding or discharging the materials.

In the vacuum feeder unit the compressed air opposite blowing device is fitted. When discharging the materials every time, the compressed air pulse oppositely blows the filter. The powder attached on the surface of filter is blown off for ensuring normal absorbing material.

Main Technical Data

|

Model |

ZKS-1 |

ZKS-2 |

ZKS-3 |

ZKS-4 |

ZKS-5 |

ZKS-6 |

ZKS-7 |

ZKS-10-6 |

ZKS-20-5 |

|

Feeding volume |

400L/h |

600L/h |

1200L/h |

2000L/h |

3000L/h |

4000L/h |

6000L/h |

6000L/h Feeding distance 10m |

5000L/h Feeding distance 20m |

|

Total power |

1.5kw |

2.2kw |

3kw |

5.5kw |

4kw |

5.5kw |

7.5kw |

7.5kw |

11kw |

|

Air Consumption |

8L/min |

8L/min |

10L/min |

12L/min |

12L/min |

12L/min |

17L/min |

34L/min |

68L/min |

|

Pressure of Air |

0.5-0.6Mpa |

0.5-0.6Mpa |

0.5-0.6Mpa |

0.5-0.6Mpa |

0.5-0.6Mpa |

0.5-0.6Mpa |

0.5-0.6Mpa |

0.5-0.6 Mpa |

0.5-0.6 Mpa |

|

Overall dimension |

Φ213*805 |

Φ290*996 |

Φ290*996 |

Φ420*1328 |

Φ420*1328 |

Φ420*1328 |

Φ420*1420 |

Φ600*1420 |

Φ800*1420 |

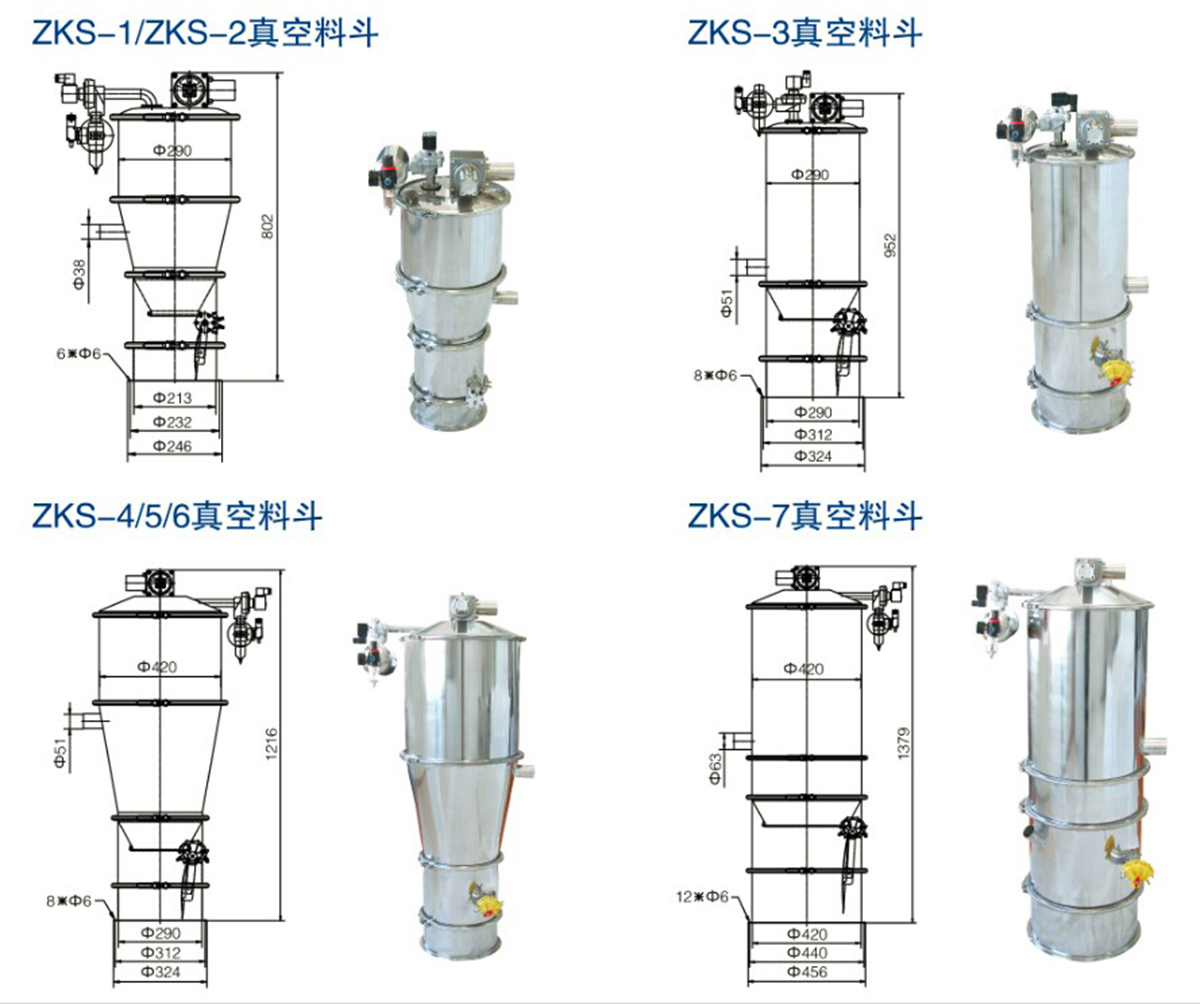

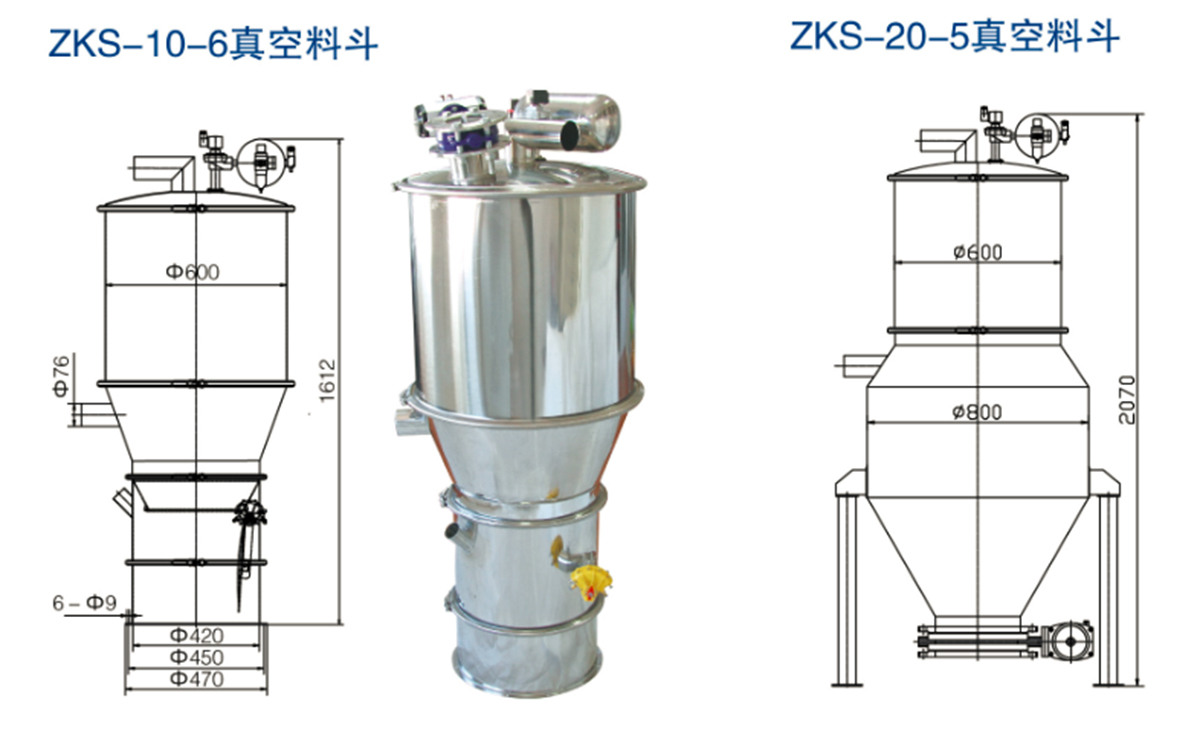

Equipment drawing

Product detail pictures:

Related Product Guide:

We offer wonderful energy in high-quality and improvement,merchandising,product sales and marketing and advertising and procedure for Vacuum Feeder Model ZKS , The product will supply to all over the world, such as: Mali, kazan, Melbourne, We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!