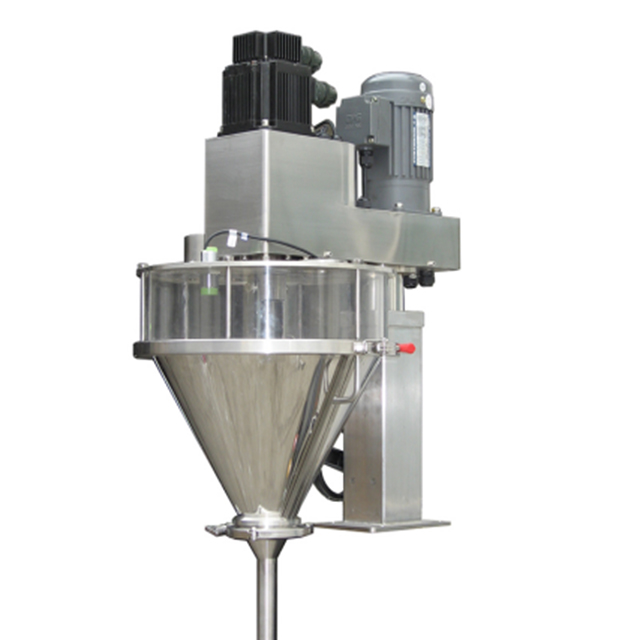

Wholesale Price China Infant Milk Powder Can Filling Machine - Semi-auto Auger filling machine with online weigher Model SPS-W100 – Shipu Machinery

Wholesale Price China Infant Milk Powder Can Filling Machine - Semi-auto Auger filling machine with online weigher Model SPS-W100 – Shipu Machinery Detail:

Main features

Stainless steel structure; Quick disconnecting hopper could be washed easily without tools.

Servo motor drive screw.

Weight feedback and proportion track get rid of the shortage of variable packaged weight for various proportion of different material.

Save the parameter of different filling weight for different materials. To save 10 sets at most

Replacing the auger parts, it is suitable for material from super thin powder to granule.

Main Technical Data

|

Can Packing Weight |

1kg – 25kg |

|

Can Packing Accuracy |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

|

Can Packing Speed |

22 – 8 times per min |

|

Power Supply |

3P AC208 – 415V 50/60Hz |

|

Compressed air |

6kg/cm3 0.1cbm/min |

|

Total Power |

2.37Kw |

|

Total Weight |

350kg |

|

Overall Dimension |

1125×975×2500mm |

|

Hopper Volume |

100L |

Configuration

|

No |

Name |

Model Specification |

PRODUCING AREA, Brand |

|

1 |

Stainless steel | SUS304 |

China |

|

2 |

PLC | Taiwan Fatek | |

|

3 |

HMI | Schneider | |

|

4 |

Filling Servo motor | TSB13152B-3NTA-1 | Taiwan TECO |

|

5 |

Filling Servo driver | ESDA40C | Taiwan TECO |

|

6 |

Agitator motor | GV-28 0.4kw,1:30 | Taiwan Yu Sin |

|

7 |

Electromagnetic valve | Taiwan SHAKO | |

|

8 |

Cylinder | MA32X150-S-CA | Taiwan Airtac |

|

9 |

Air Filter and booster | AFR-2000 | Taiwan Airtac |

|

10 |

Switch | HZ5BGS | Wenzhou Cansen |

|

11 |

Circuit breaker | Schneider | |

|

12 |

Emergency switch |

Schneider | |

|

13 |

EMI Filter | ZYH-EB-10A | Beijing ZYH |

|

14 |

Contactor | CJX2 1210 | Wenzhou CHINT |

|

15 |

Heat relay | NR2-25 | Wenzhou CHINT |

|

16 |

Relay | MY2NJ 24DC |

Japan Omron |

|

17 |

Switching power supply | Changzhou Chenglian | |

|

18 |

AD Weighing Module | MAINFILL | |

|

19 |

Loadcell | IL-150 | Mettler Toledo |

|

20 |

Photo sensor | BR100-DDT | Korea Autonics |

|

21 |

Level sensor | CR30-15DN | Korea Autonics |

Product detail pictures:

Related Product Guide:

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Wholesale Price China Infant Milk Powder Can Filling Machine - Semi-auto Auger filling machine with online weigher Model SPS-W100 – Shipu Machinery , The product will supply to all over the world, such as: Ottawa, Bangladesh, Adelaide, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!