High Quality Auger Filler - 7Automatic Powder Can Filling Machine (1 line 2fillers) Model SPCF-W12-D135 – Shipu Machinery

High Quality Auger Filler - 7Automatic Powder Can Filling Machine (1 line 2fillers) Model SPCF-W12-D135 – Shipu Machinery Detail:

Main features

One line dual fillers, Main & Assist can filling to keep work in high-precision.

Can-up and horizontal transmitting is controlled by servo and pneumatic system, be more accurate, more speed.

Servo motor and servo driver control the screw, keep stable and accurate

Stainless steel structure, Split hopper with polishing inner-out make it to cleaned easily.

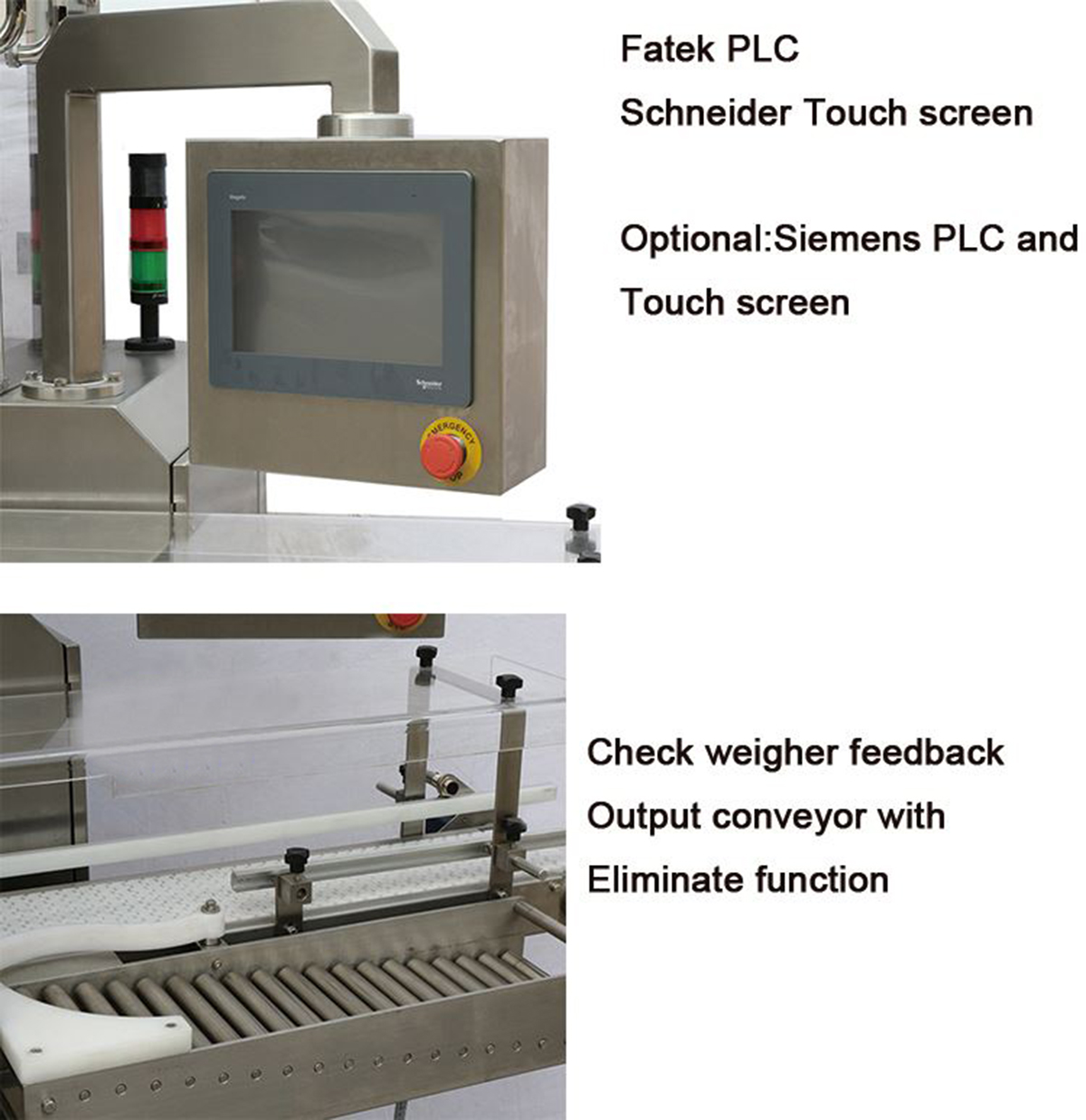

PLC & touch screen make it be easy of operation.

Fast-respond weighing system make the strongpoint to real

The handwheel make the exchange of different filings to be easily.

Dust-collecting cover meet the pipeline and protect environment to pollution.

Horizontal straight design make the machine in little area

Settled screw setup make no metal pollution in producing

Process: can-into → can-up → vibration →can filling → vibration → vibration → weighing & tracing → reinforce → weight checking → Can-out

With whole system central control system.

Technical Specification

| Model | SP-W12-D140 | SP-W12-D210 |

| Dosing mode | Dual filler filling with online weighing | Dual filler filling with online weighing |

| Filling Weight | 100 – 1500g | 100 – 5000g |

| Container Size | Φ60-140mm; H 60-260mm | Φ60-210mm; H 60-260mm |

| Filling Accuracy | 100-500g, ≤±1g; 500-1000g,≤±2g; >1000g, ≤±3-4g | 100-500g, ≤±1g; 500-1000g,≤±2g; >1000g, ≤±3-4g |

| Filling Speed | 45 cans/min (#502) | 35 cans/min (#603) |

| Power Supply | 3P AC208-415V 50/60Hz | 3P, AC208-415V, 50/60Hz |

| Total Power | 3.4 kw | 4.75kw |

| Total Weight | 450kg | 650kg |

| Air Supply | 0.2cbm/min, 0.6Mpa | 0.2cbm/min, 0.6Mpa |

| Overall Dimension | 2650×1075×2683mm | 3200x1170x2920mm |

| Hopper Volume | 50L(Main) 11L (Assist) | 75L(Main) 25L (Assist) |

Main function

Product detail pictures:

Related Product Guide:

Our merchandise are broadly identified and trusted by end users and can satisfy continually developing economic and social requires for High Quality Auger Filler - 7Automatic Powder Can Filling Machine (1 line 2fillers) Model SPCF-W12-D135 – Shipu Machinery , The product will supply to all over the world, such as: Hungary, Madagascar, Turkmenistan, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The items to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!