Horizontal Ribbon Mixer Model SPM-R

Descriptive abstract

The Horizontal Ribbon Mixer consist of U-Shape tank, spiral and drive parts. The spiral is dual structure. Outer spiral make the material move from the sides to the center of the tank and the inner screw conveyor the material from the center to the sides to get the convective mixing. Our DP series Ribbon mixer can mix many kinds material especially for the powder and granular which with stick or cohesion character, or add a little liquid and paste material into powder and granular material. The mixture effect is high. The cover of the tank can be made as open in order to cleaning and change parts easily.

Main features

Mixer with Horizontal tank , single shaft with dual spiral symmetry circle structure.

The top cover of the U Shape tank has the entrance for material. It can be also designed with spray or add liquid device according the customer’s needs. Inside the tank there equipped the axes rotor which consist of, corss support and spiral ribbon.

Under the bottom of the tank, there has a flap dome valve (pneumatic control or manual control) of the center. The valve is arc design that assure no material deposit and without no dead angle when mixing. Reliable regula- seal prohibit the leakage between the frequent close and open.

The discon-nexion ribbon of the mixer can make the material mixed with more high speed and uniformity in short time.

This mixer also can be designed with the function to keep cold or heat. Add one layer outside the tank and put into medium into the interlayer to get the mixing material cold or heat. Usually use water for cool and hot steam or use electrical for heat.

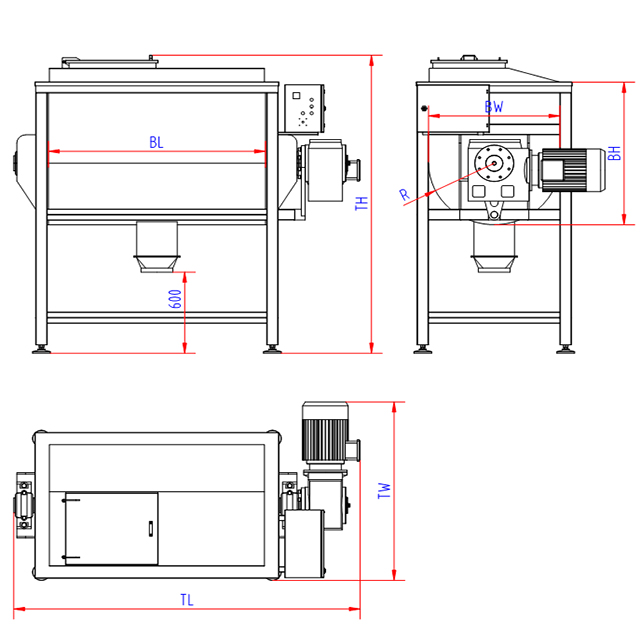

Main Technical Data

|

Model |

SPM-R80 |

SPM-R200 |

SPM-R300 |

SPM-R500 |

SPM-R1000 |

SPM-R1500 |

SPM-R2000 |

|

Effective Volume |

80L |

200L |

300L |

500L |

1000L |

1500L |

2000L |

|

Fully Volume |

108L |

284L |

404L |

692L |

1286L |

1835L |

2475L |

|

Turning Speed |

64rpm |

64rpm |

64rpm |

56rpm |

44rpm |

41rpm |

35rpm |

|

Total Weight |

180kg |

250kg |

350kg |

500kg |

700kg |

1000kg |

1300kg |

|

Total Power |

2.2kw |

4kw |

5.5kw |

7.5kw |

11kw |

15kw |

18kw |

|

Length(TL) |

1230 |

1370 |

1550 |

1773 |

2394 |

2715 |

3080 |

|

Width(TW) |

642 |

834 |

970 |

1100 |

1320 |

1397 |

1625 |

|

Height(TH) |

1540 |

1647 |

1655 |

1855 |

2187 |

2313 |

2453 |

|

Length(BL) |

650 |

888 |

1044 |

1219 |

1500 |

1800 |

2000 |

|

Width(BW) |

400 |

554 |

614 |

754 |

900 |

970 |

1068 |

|

Height(BH) |

470 |

637 |

697 |

835 |

1050 |

1155 |

1274 |

|

(R) |

200 |

277 |

307 |

377 |

450 |

485 |

534 |

|

Power Supply |

3P AC208-415V 50/60Hz |

||||||