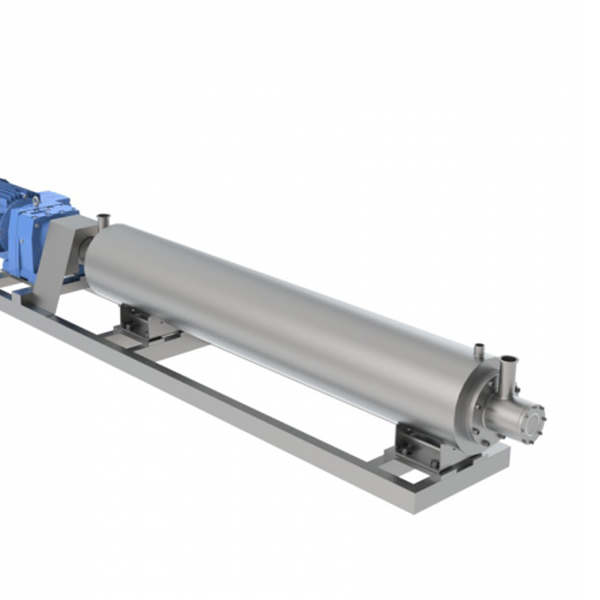

Manufacturer for Soap Stamper - Super-charged refiner Model 3000ESI-DRI-300 – Shipu Machinery

Manufacturer for Soap Stamper - Super-charged refiner Model 3000ESI-DRI-300 – Shipu Machinery Detail:

General Flowchart

Main feature

New developed pressure-boosting worm has increased the refiner’s output by 50% and the refiner has good cooling system and higher pressure, no-reverse movement of soap inside the barrels. Better refining is achieved;

Frequency control of speeds make operation more easy;

Mechanical design:

① All parts in contact with soap are in stainless steel 304 or 316;

② Worm diameter is 300 mm, made from aviation wear-resisting and corrosion-resting aluminum-magnesium alloy. Or from stainless steel 304;

③ Worm barrel is from high-strength, pressure-resist stainless steel, and with good cooling system;

④ Gear reducer is supplied by Zambello, Italy.

⑤ The worm shaft support sleeve is from engineering plastic of Igus, Germany.

Electrical:

1. Switches, contactors are supplied by Schneider, France;

2. Frequency changer to control the speed. The controls are supplied by ABB, Switzerland.

Product detail pictures:

Related Product Guide:

We're going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for Manufacturer for Soap Stamper - Super-charged refiner Model 3000ESI-DRI-300 – Shipu Machinery , The product will supply to all over the world, such as: Roman, Jordan, Plymouth, With the highest standards of product quality and service, our products have been exported to more than 25 countries like the USA, CANADA, GERMANY, FRANCE, UAE, Malaysia and so on.We are very pleased to serve customers from all over the world!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.