Plasticator-SPCP

Function and Flexibility

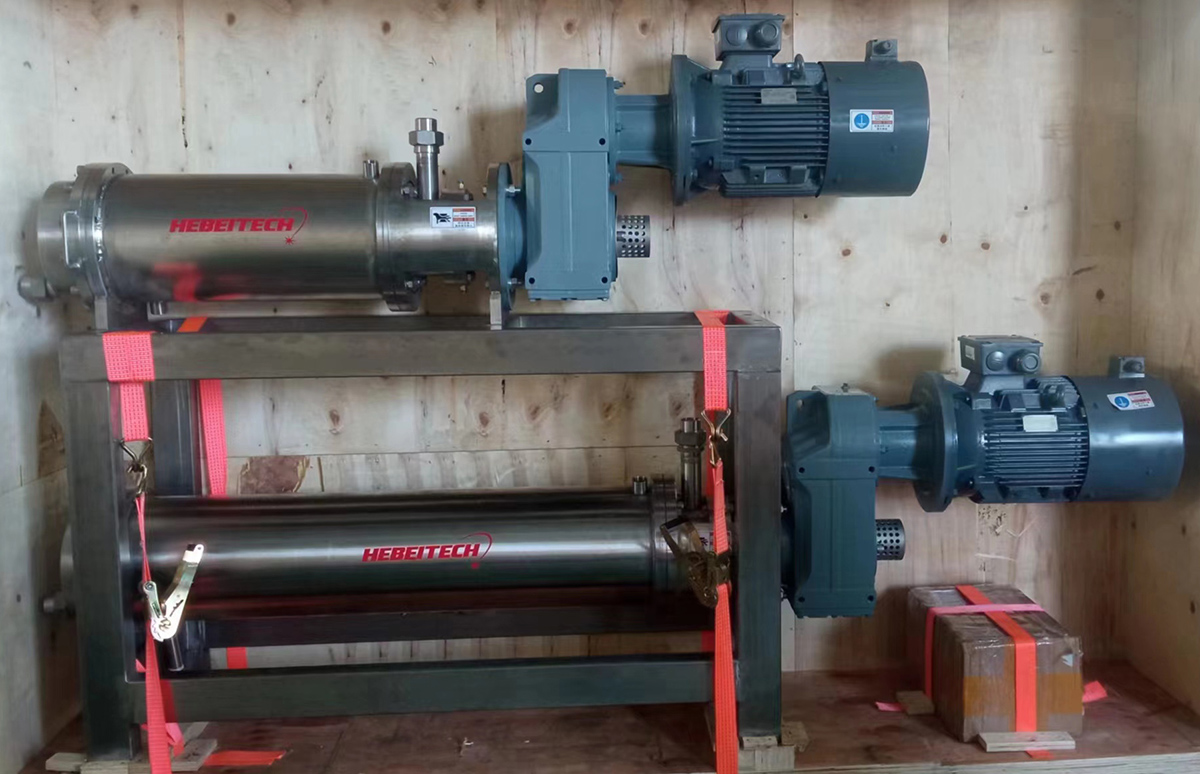

The Plasticator, which is normally equipped with pin rotor machine for production of shortening, is a kneading and plasticising machine with 1 cylinder for intensive mechanical treatment for obtaining an extra degree of plasticity of the product.

High Standards of Hygiene

The Plasticator is designed to meet the highest standards of hygiene. All product parts subject to be in contact with food are made of AISI 316 stainless steel and all the product seals are in sanitary design.

Shaft Sealing

The mechanical product seal is of the semi-balanced type and of sanitary design. The sliding parts are made of tungsten carbide, which ensures very long durability.

Optimize floor space

We know how important it is to optimize floor space, so we have designed to assemble the pin rotor machine and plasticator on the same frame, and therefore also very easy to clean.

Material:

All product contacting parts are of stainless steel AISI 316L.

Technical Spec.

| Technical Spec. | Unit | 30L (Volume to be customized) |

| Nominal Volume | L | 30 |

| Main Power (ABB motor) | kw | 11/415/V50HZ |

| Dia. Of Main Shaft | mm | 82 |

| Pin Gap Space | mm | 6 |

| Pin-Inner Wall Space | m2 | 5 |

| Inner Dia./Length of Cooling Tube | mm | 253/660 |

| Rows of Pin | pc | 3 |

| Norminal Pin Rotor Speed | rpm | 50-700 |

| Max.Working Pressure (material side) | bar | 120 |

| Max.Working Pressure (hot water side) | bar | 5 |

| Processing Pipe Size | DN50 | |

| Water Supply Pipe Size | DN25 | |

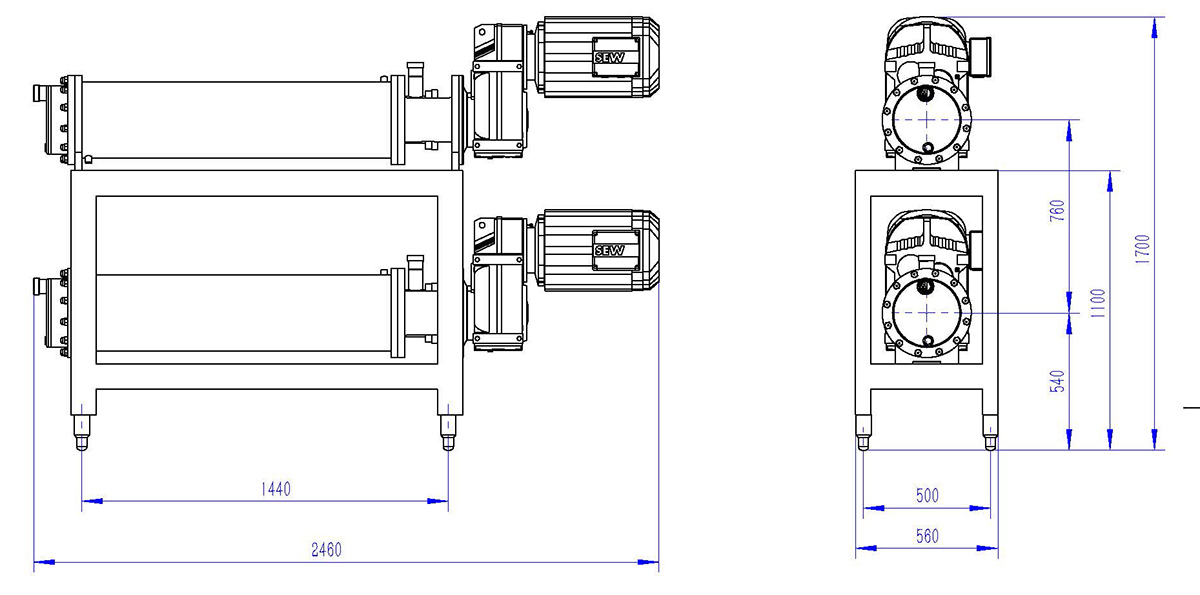

| Overall Dimension | mm | 2500*560*1560 |

| Gross Weight | kg |

1150 |

Equipment Drawing