Margarine Plant

-

SPXU series scraper heat exchanger

SPXU series scraper heat exchanger unit is a new type of scraper heat exchanger, can be used to heat and cool a variety of viscosity products, especially for very thick and viscous products, with strong quality, economic health, high heat transfer efficiency, affordable features.

-

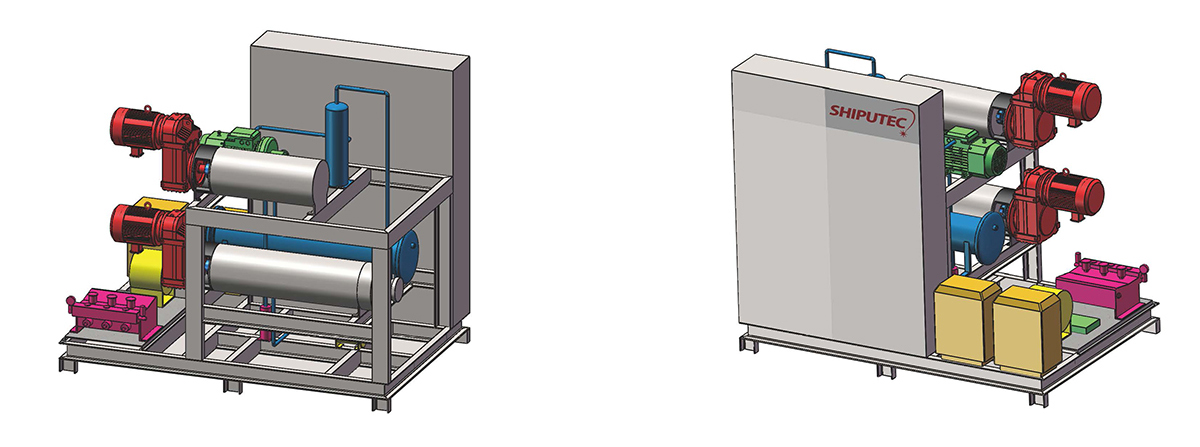

New Designed Integrated Margarine & Shortening Processing Unit

n the current market, the shortening and margarine equipment generally choose separate form, including mixing tank, emulsifying tank, production tank, filter, high pressure pump, votator machine (scraped surface heat exchanger), pin rotor machine (kneading machine), refrigeration unit and other independent equipment. Users need to purchase separate equipment from different manufacturers and connect pipelines and lines at the user site;

Split production line equipment layout is more scattered, occupies a larger area, the need for on-site pipeline welding and circuit connection, the construction period is long, difficult, the site technical personnel requirements are relatively high;

Because the distance from the refrigeration unit to the votator machine ( scraped surface heat exchanger ) is far, the refrigerant circulation pipeline is too long, which will affect the refrigeration effect to a certain extent, resulting in high energy consumption;

And since the devices come from different manufacturers, this can lead to compatibility issues. The upgrade or replacement of one component may require a reconfiguration of the entire system.

Our newly developed integrated shortening & margarine processing unit on the basis of maintaining the original process, the appearance, structure, pipeline, electric control of the relevant equipment has been unified deployment, compared with the original traditional production process has the following advantages:

1. All equipment is integrated on one pallet, greatly reducing the footprint, convenient loading and unloading and land and sea transportation.

2. All piping and electronic control connections can be completed in advance in the production enterprise, reducing the user’s site construction time and reducing the difficulty of construction;

3. Greatly shorten the length of refrigerant circulation pipe, improve the refrigeration effect, reduce the refrigeration energy consumption;

4. All the electronic control parts of the equipment are integrated in a control cabinet and controlled in the same touch screen interface, simplifying the operation process and avoiding the risk of incompatible systems;

5. This unit is mainly suitable for users with limited workshop area and low level of on-site technical personnel, especially for non-developed countries and regions outside China. Due to the reduction of equipment size, shipping costs are greatly reduced; Customers can start up and run with a simple circuit connection on site, simplifying the installation process and difficulty on site, and greatly reducing the cost of sending engineers to foreign site installati

-

Margarine Production Process

Margarine production includes two parts: raw material preparation and cooling and plasticizing. The main equipment includes preparation tanks, HP pump, votator (scraped surface heat exchanger), pin rotor machine, refrigeration unit, margarine filling machine and etc.

-

Scraped Surface Heat Exchangers-SP Series

Since the year of 2004, Shipu Machinery has been focusing on the field of scraped surface heat exchangers. Our scraped surface heat exchangers have a very high reputation and reputation in the Asia market. Shipu Machinery has long time offered the best price machines to the bakery industry, food industry and the dairy product industry, like Fonterra group, Wilmar group, Puratos, AB Mauri and etc. Our scraper heat exchangers price is only about 20%-30% of similar products in Europe and America, and is welcomed by many factories. The manufacturing plant uses the good-quality and inexpensive SP series scraped surface heat exchangers made in China to rapidly increase production capacity and reduce production costs, the Goods produced by their factory have excellent market competitiveness and cost advantages, quickly occupied most market share.

-

Sheet margarine packaging line

The sheet margarine packaging line is normally used for four side sealing or double face film laminating of sheet margarine, it will be along with the resting tube, after the sheet margarine is extruded from the resting tube, it will be cut into required size, then packed by film.

-

Votator-Scraped Surface Heat Exchangers-SPX-PLUS

SPX-Plus series scraped surface heat exchanger is specially designed for high viscosity food industry,It is especially suitable for food manufacturers of puff pastry margarine, table margarine and shortening. It has excellent cooling capacity and excellent crystallization capacity. It integrates Ftherm® liquid level control refrigeration system, Hantech evaporation pressure regulation system and Danfoss oil return system. It is equipped with 120bar pressure resistant structure as standard, and the maximum equipped motor power is 55kW, it is suitable for the continuous production of fat and oil products with viscosity up to1000000 cP.

Suitable for margarine prodution, margarine plant, margarine machine, shortening processing line, scraped surface heat exchanger, votator and etc.

-

Scraped Surface Heat Exchanger-SPA

Our chilling unit (A unit) is modeled after the Votator type of scraped surface heat exchanger and combines the special features of the European design to take advantage of the two worlds. It shares many small interchangeable components. Mechanical seal and scraper blades are typical interchangeable parts.

The heat transfer cylinder consists of a pipe in pipe design with inner pipe for product and outer pipe for cooling refrigerant. The inner tube is designed for very high pressure process operation. The jacket is designed for flooded direct evaporative cooling of either Freon or ammonia.

Suitable for margarine prodution, margarine plant, margarine machine, shortening processing line, scraped surface heat exchanger, votator and etc.

-

Surface Scraped Heat Exchanger-Votator machine-SPX

SPX series Scraped surface heat exchanger is particularly suited for continuous heating and cooling of viscous, sticky, heat-sensitive and particulate food products. It can operate with a wide range of media products. It is used in continuous processes such as heating, aseptic cooling, cryogenic cooling, crystallization, disinfection, pasteurization and gelation.

Suitable for margarine prodution, margarine plant, margarine machine, shortening processing line, scraped surface heat exchanger, votator and etc.

起酥油设备,人造黄油设备,人造奶油设备,刮板式换热器,棕榈油加工设备