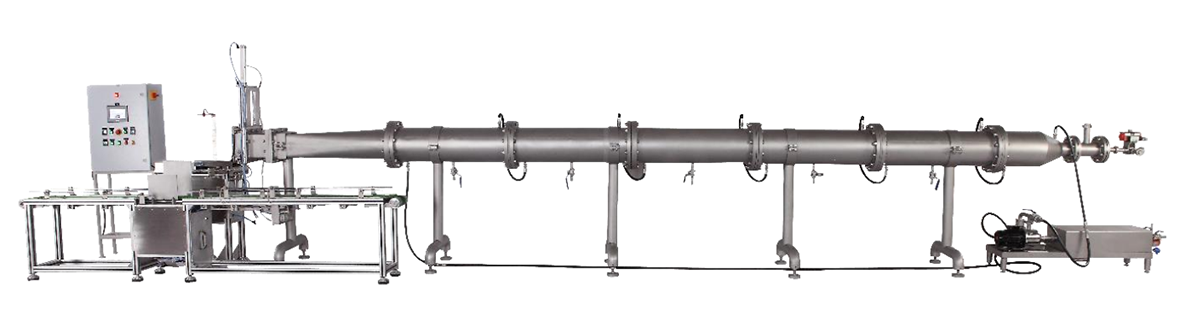

Resting Tube-SPB

Working Principle

The Resting Tube unit consists of multi-sections of jacketed cylinders to provide the desired retention time for proper crystal growth. Internal orifice plates are provided to extrude and worked the product to modify the crystal structure to give the desired physical properties.

The outlet design is a transition piece to accept a customer specific extruder, The custom extruder is required to produce sheet puff pastry or block margarine and is adjustable for thickness.

he advantage of this system is : high precision, high pressure endurance, excellent sealing, easy to install and dismantle, convenient for cleaning.

This system is suitable for producing puff pastry margarine, and we receive positive comment from customers. we adopt the advanced PID control system to regulate the temperature of constant temperature water in the jacket.