Sheet Margarine Film Lamination Line

Sheet Margarine Film Lamination Line

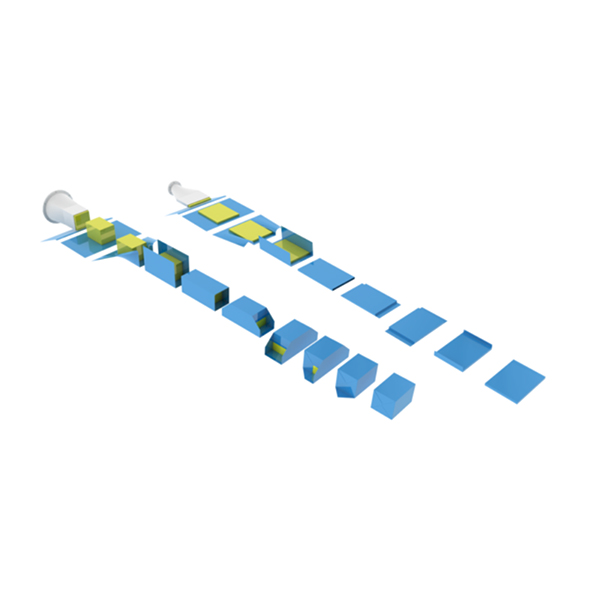

The working process:

- The cut block oil will fall on the packaging material, with the servo motor driven by the conveyor belt to accelerate a set length to ensure the set distance between the two pieces of oil.

- Then transported to the film cutting mechanism, quickly cut off the packaging material, and transported to the next station.

- The pneumatic structure on both sides will rise from the two sides, so that the package material is attached to the grease, and then overlap to the middle, and transmit the next station.

- The servo motor drive direction mechanism, after detecting the grease will immediately do the clip and quickly adjust the 90° direction.

- After detecting grease, the lateral sealing mechanism will drive the servo motor to quickly turn forward and then reverse, so as to achieve the purpose of pasting the packaging material on both sides to the grease.

- The packaged grease will be adjusted again by 90° in the same direction as before and after the package, and enter the weighing mechanism and the removal mechanism.

Weighing mechanism and rejection

Online weighing method can quickly and continuously weigh and feedback, such as out of tolerance will be automatically eliminated.

Technical parameter

Sheet Margarine Specifications:

- Sheet length : 200mm≤L≤400mm

- Sheet width : 200mm≤W≤320mm

- Sheet height : 8mm≤H≤60mm

Block Margarine Specifications:

- Block length : 240mm≤L≤400mm

- Block width : 240mm≤W≤320mm

- Block height : 30mm≤H≤250mm

Packaging materials : PE film, composite paper, kraft paper

Output

Sheet margarine : 1-3T/h (1kg/pc), 1-5T/h (2kg/pc)

Block margarine : 1-6T/h (10kg per piece)

Power : 10kw, 380v50Hz

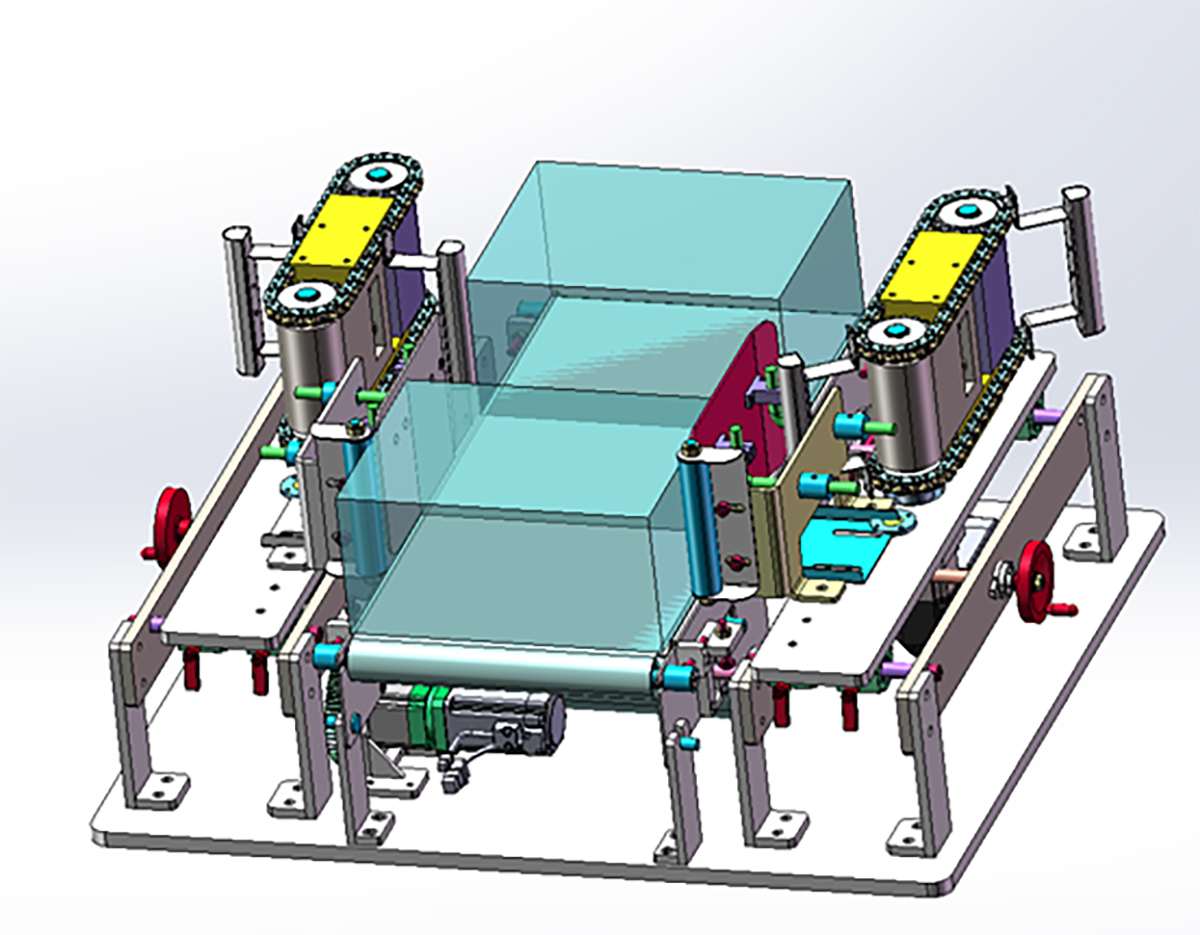

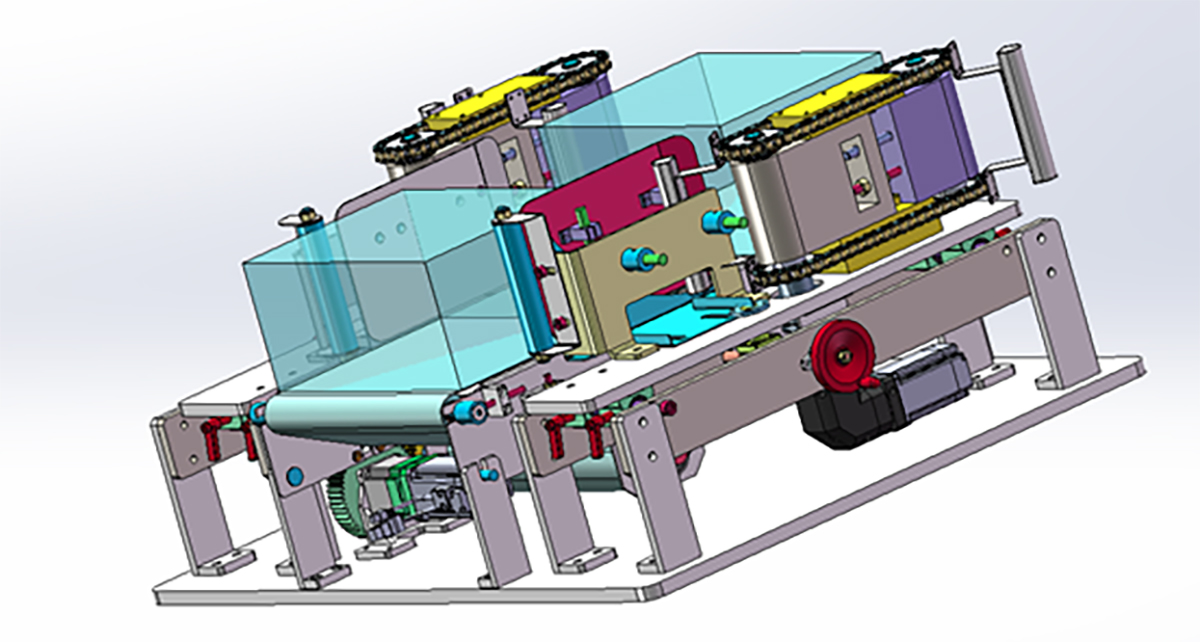

Equipment Structure

Automatic cutting part:

- Automatic constant temperature cutting mechanism

Technical features: After the equipment is started, it is automatically heated to the set temperature and kept at a constant temperature.

Cutter servo mechanism: pneumatic actuator, through the mechanical structure to complete the up and down, movement and forward and backward movement of the thermostat knife, and ensure that the moving speed is consistent with the transmission speed of grease. Ensure the beauty of grease incision to the greatest extent.

2.Film release mechanism

This equipment can be used for PE film, composite paper, kraft paper and other packaging materials.

The feeding method is built-in feeding, convenient and simple to quickly load and unload film coil, automatic discharge during operation, synchronous supply, automatic start and stop.

Automatic continuous film change, to achieve non-stop film replacement, film roll joint automatically removed, only manual replacement of film roll.

3.The transmission mechanism is constant tension, automatic correction.