Wholesale Price Albumen Powder Filling Machine - High Speed Automatic Can Filling Machine (1 lines 3 fillers) Model SP-L3 – Shipu Machinery

Wholesale Price Albumen Powder Filling Machine - High Speed Automatic Can Filling Machine (1 lines 3 fillers) Model SP-L3 – Shipu Machinery Detail:

Main features

One line dual fillers, Main & Assist filling to keep work in high-precision.

Can-up and horizontal transmitting is controlled by servo and pneumatic system, be more accurate, more speed.

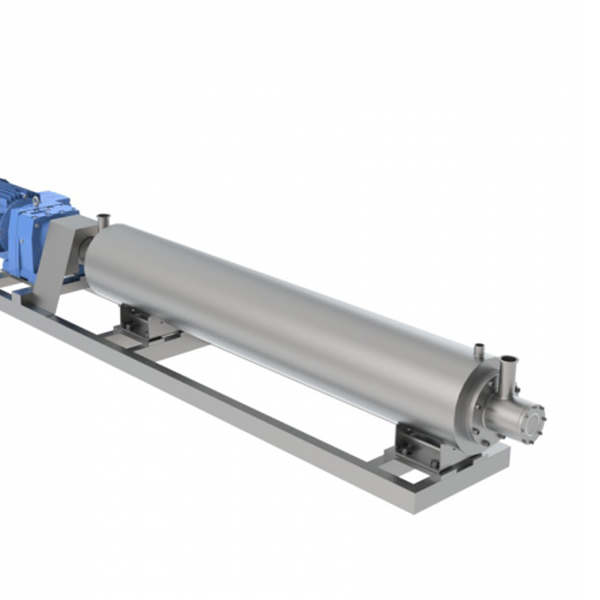

Servo motor and servo driver control the screw, keep stable and accurate

Stainless steel structure, Split hopper with polishing inner-out make it to cleaned easily.

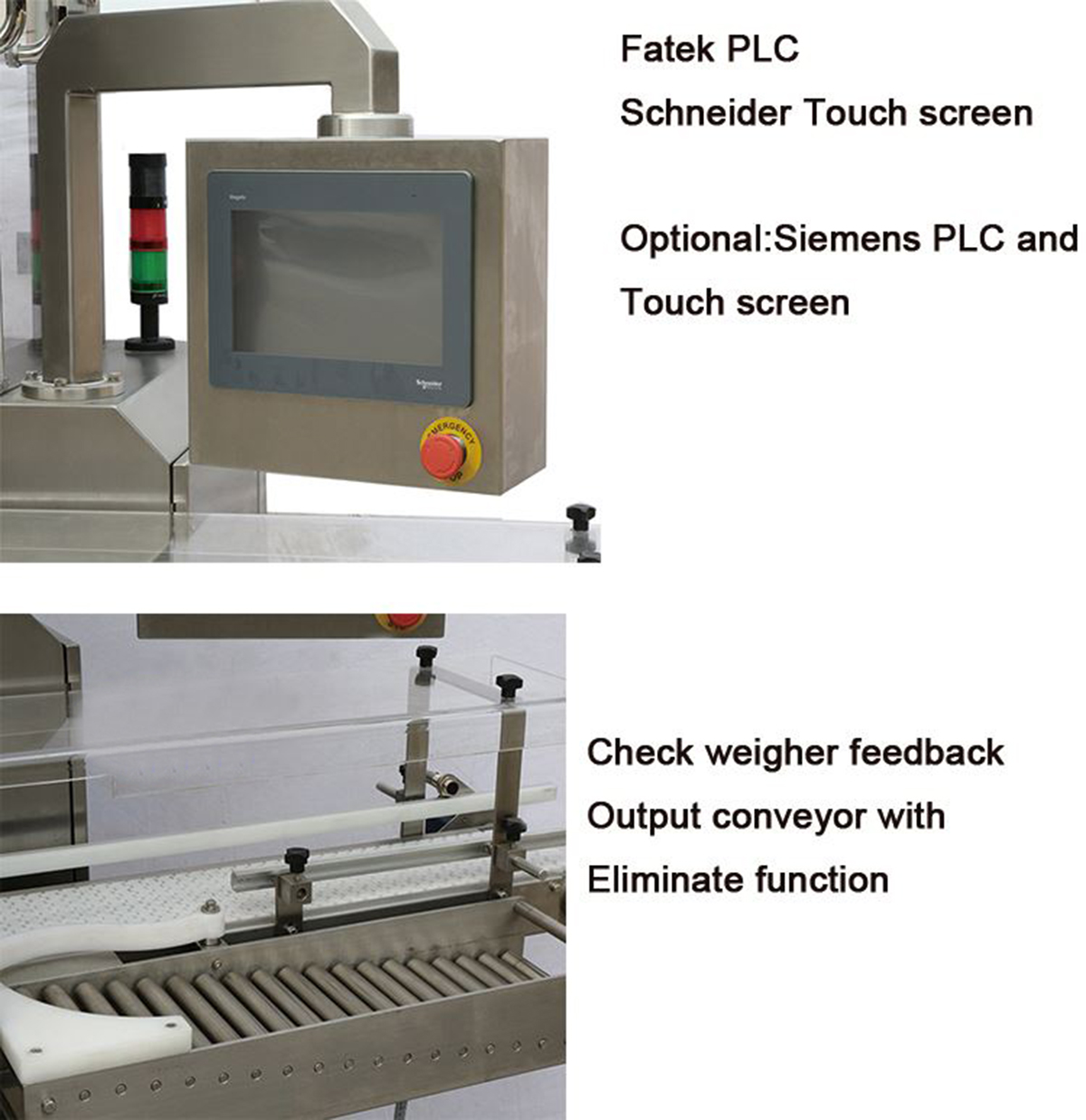

PLC & touch screen make it be easy of operation.

Fast-respond weighing system make the strongpoint to real

The handwheel make the exchange of different filings to be easily.

Dust-collecting cover meet the pipeline and protect environment to pollution.

Horizontal straight design make the machine in little area

Settled screw setup make no metal pollution in producing

Process: can-into → can-up → vibration → filling → vibration → vibration → weighing & tracing → reinforce → weight checking → Can-out

With whole system central control system.

Main technical data

|

Dosing mode |

Double lines dual filler filling with online weighing |

| Filling Weight | 100 – 2000g |

| Container Size | Φ60-135mm; H 60-260mm |

| Filling Accuracy | 100-500g, ≤±1g; ≥500g,≤±2g |

| Filling Speed | 80 – 100 cans/min |

| Power Supply | 3P AC208-415V 50/60Hz |

| Total Power | 5.1 kw |

| Total Weight | 650kg |

| Air Supply | 6kg/cm 0.3cbm/min |

| Overall Dimension | 2920x1400x2330mm |

| Hopper Volume | 85L(Main) 45L (Assist) |

Main function

Equipment drawing

Product detail pictures:

Related Product Guide:

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with the good quality at the reasonable price for Wholesale Price Albumen Powder Filling Machine - High Speed Automatic Can Filling Machine (1 lines 3 fillers) Model SP-L3 – Shipu Machinery , The product will supply to all over the world, such as: South Korea, Surabaya, Vietnam, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!