Margarine Plant

-

Smart Refrigerator Unit Model SPSR

Specially made for oil crystallization

The design scheme of the refrigeration unit is specially designed for the characteristics of Hebeitech quencher and combined with the characteristics of oil processing process to meet the refrigeration demand of oil crystallization

Suitable for margarine prodution, margarine plant, margarine machine, shortening processing line, scraped surface heat exchanger, votator and etc.

-

Emulsification Tanks (Homogenizer)

The tank area includes tanks of oil tank, water phase tank, additives tank, emulsification tank (homogenizer), standby mixing tank and etc. All tanks are SS316L material for food grade, and meet the GMP standard.

Suitable for margarine prodution, margarine plant, margarine machine, shortening processing line, scraped surface heat exchanger, votator and etc.

-

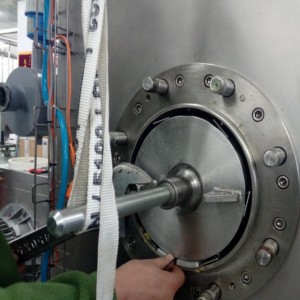

Votator-SSHEs Service, maintenance, repair, renovation, optimization,spare parts, extended warranty

We provide all brands of Scraped Surface Heat Exchangers, votator services in the world, including maintenance, repair, optimization,renovation, continuously improve product quality, Wearing parts, spare parts, extended warranty.

-

Margarine Filling Machine

It is a semi-automatic filling machine with double filler for margarine filling or shortening filling. The machine adopts Siemens PLC control and HMI, speed to be adjusted by frequency inverter. Filling speed is fast at beginning, and then getting slow. After the filling is completed, it will suck in the filler mouth in case of any oil dropping. The machine can record different recipe for different filling volume. It could be measured by volume or weight. With function of quick correction for filling precision, high filling speed, precision and easy operation. Suitable for 5-25L package quantitative packaging.

-

Pilot Margarine Plant Model SPX-LAB (Lab scale)

Pilot margarine/shortening plant consists of small emulsification tank, pasteurizer system, Scraped Surface Heat Exchanger, refrigerant flooded evaporative cooling system, pin worker machine, packaging machine, PLC and HMI control system and electrical cabinet. An optional Freon compressor is available.

Every component is designed and fabricated in-house to simulate our full scale production equipment. All critical components are imported brand, including Siemens, Schneider and Parkers etc. The system could use either ammonia or Freon for chilling.

Suitable for margarine prodution, margarine plant, margarine machine, shortening processing line, scraped surface heat exchanger, votator and etc.

-

Sheet Margarine Stacking & Boxing Line

This stacking & boxing line includes sheet/block margarine feeding, stacking, sheet/block margarine feeding into box, adhensive spraying, box forming & box sealing and etc., it is good option for replacement of manual sheet margarine packaging by box.

-

Sheet Margarine Film Lamination Line

- The cut block oil will fall on the packaging material, with the servo motor driven by the conveyor belt to accelerate a set length to ensure the set distance between the two pieces of oil.

- Then transported to the film cutting mechanism, quickly cut off the packaging material, and transported to the next station.

- The pneumatic structure on both sides will rise from the two sides, so that the package material is attached to the grease, and then overlap to the middle, and transmit the next station.

- The servo motor drive direction mechanism, after detecting the grease will immediately do the clip and quickly adjust the 90° direction.

- After detecting grease, the lateral sealing mechanism will drive the servo motor to quickly turn forward and then reverse, so as to achieve the purpose of pasting the packaging material on both sides to the grease.

- The packaged grease will be adjusted again by 90° in the same direction as before and after the package, and enter the weighing mechanism and the removal mechanism.