Products

-

Emulsification Tanks (Homogenizer)

The tank area includes tanks of oil tank, water phase tank, additives tank, emulsification tank (homogenizer), standby mixing tank and etc. All tanks are SS316L material for food grade, and meet the GMP standard.

Suitable for margarine prodution, margarine plant, margarine machine, shortening processing line, scraped surface heat exchanger, votator and etc.

-

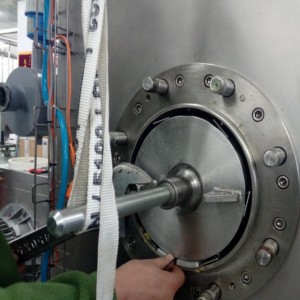

Votator-SSHEs Service, maintenance, repair, renovation, optimization,spare parts, extended warranty

We provide all brands of Scraped Surface Heat Exchangers, votator services in the world, including maintenance, repair, optimization,renovation, continuously improve product quality, Wearing parts, spare parts, extended warranty.

-

Margarine Filling Machine

It is a semi-automatic filling machine with double filler for margarine filling or shortening filling. The machine adopts Siemens PLC control and HMI, speed to be adjusted by frequency inverter. Filling speed is fast at beginning, and then getting slow. After the filling is completed, it will suck in the filler mouth in case of any oil dropping. The machine can record different recipe for different filling volume. It could be measured by volume or weight. With function of quick correction for filling precision, high filling speed, precision and easy operation. Suitable for 5-25L package quantitative packaging.

-

Pilot Margarine Plant Model SPX-LAB (Lab scale)

Pilot margarine/shortening plant consists of small emulsification tank, pasteurizer system, Scraped Surface Heat Exchanger, refrigerant flooded evaporative cooling system, pin worker machine, packaging machine, PLC and HMI control system and electrical cabinet. An optional Freon compressor is available.

Every component is designed and fabricated in-house to simulate our full scale production equipment. All critical components are imported brand, including Siemens, Schneider and Parkers etc. The system could use either ammonia or Freon for chilling.

Suitable for margarine prodution, margarine plant, margarine machine, shortening processing line, scraped surface heat exchanger, votator and etc.

-

Pelletizing Mixer with three-drives Model ESI-3D540Z

Pelletizing Mixer with three-drives for toilet or transparent soap is a new developed bi-axial Z agitator.This type of mixer has agitator blade with 55° twist, to increase the mixing arc length, so to have soap inside the mixer stronger mixing. At the bottom of the mixer, an extruder’s screw is added. That screw can rotate in both directions. During the mixing period, the screw rotates in one direction to recirculate the soap to the mixing area, whine during soap discharging period, the screw rotates in another direction to extrude the soap out in form of pellets to feed the three-roll mill, installed below the mixer. The two agitators run in opposite directions and with different speeds, and are driven by two German SEW gear reducers separately. The rotating speed of fast agitator is 36 r/min while the slow agitator is 22 r/min. The screw diameter is 300 mm, rotating speed 5 to 20 r/min.

-

High-precision Two-scrapers Bottom Discharged roller Mill

This bottom discharged mill with three rolls and two scrapers are design for professional soap producers. The soap particle size can reach 0.05 mm after milling. The size of milled soap is uniformly distributed, that means 100% of efficiency. The 3 rolls, made from stainless alloy 4Cr, are driven by 3 gear reducers with their own speed. The gear reducers are supplied by SEW, Germany. The clearance between rolls can be adjusted independently; the adjusting error is 0.05 mm max. The clearance is fixed by shrinking sleeves supplied by KTR, Germany, and set screws.

-

Super-charged refiner Model 3000ESI-DRI-300

The refining using screw refiner is traditional in soap finishing processes. The milled soap is further refined and filtered to make the soap more fine and smooth. So this machine is essential in making high-grade toilet soap and translucent soaps.

-

Super-charged plodder for translucent /toilet soap

This is a two-stage extruder. Each worm is speed adjustable. The upper stage is for refining of soap, while the lower stage is for plodding of the soap. Between the two stages there is a vacuum chamber where air is evacuated from the soap to eliminate air bubbles in the soap. The high pressure in the lower barrel make soap compact then the soap is extruded out to form continuous soap bar.