Votator-Scraped Surface Heat Exchangers-SPX-PLUS

Similar Competitive Machines

The international competitors of SPX-plus SSHEs are Perfector series, Nexus series and Polaron series SSHEs under gerstenberg, Ronothor series SSHEs of RONO company and Chemetator series SSHEs of TMCI Padoven company.

Technical spec.

| Plus Series | 121AF | 122AF | 124AF | 161AF | 162AF | 164AF |

| Nominal Capacity Puff Pastry Margarine @ -20°C (kg/h) | N/A | 1150 | 2300 | N/A | 1500 | 3000 |

| Nominal Capacity Table Margarine @-20°C (kg/h) | 1100 | 2200 | 4400 | 1500 | 3000 | 6000 |

| Nominal Capacity Shortening @-20°C (kg/h) | 1500 | 3000 | 6000 | 2000 | 4000 | 8000 |

| Number of Refrigerant circuits | 1 | 2 | 4 | 1 | 2 | 4 |

| Number of Tubes per Refrigerant circuit | 1 | 1 | 1 | 1 | 1 | 1 |

| Motor for Puff Pastry Margarine (kw) | N/A | 22+30 | 18.5+22+30+37 | 37+45 | 30+37+45+55 | |

| Motor for Table Margarine (kw) | 18.5 | 18.5+18.5 | 18.5+18.5+22+22 | 30 | 22+30 | 22+30+37+45 |

| Motor for Shortening (kw) | 18.5 | 18.5+18.5 | 18.5+18.5+22+22 | 30 | 22+30 | 22+22+30+30 |

| Number of Gear Box | 1 | 2 | 4 | 1 | 2 | 4 |

| Cooling Surface per Tube (m2) | 0.61 | 0.61 | 0.61 | 0.84 | 0.84 | 0.84 |

| Annular Space (mm) | 10 | 10 | 10 | 10 | 10 | 10 |

| Capacity @ -20°C (kw) | 50 | 100 | 200 | 80 | 160 | 320 |

| Max. Working Pressure @ Media Side (Bar) | 20 | 20 | 20 | 20 | 20 | 20 |

| Max. Working Pressure @ Product Side (Bar) | 120 | 120 | 120 | 120 | 120 | 120 |

| Min. Working Temperature °C | -29 | -29 | -29 | -29 | -29 | -29 |

| Chilling Tube Dimension (Dia./Length, mm) | 160/1200 | 160/1200 | 160/1200 | 160/1600 | 160/1600 | 160/1600 |

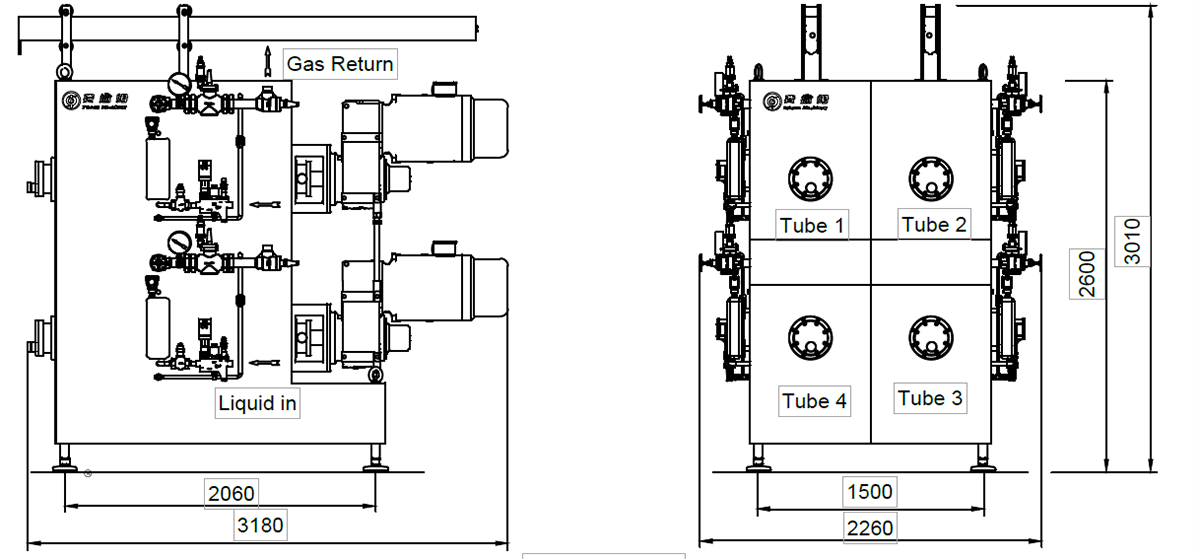

Machine Drawing

Write your message here and send it to us