Manufacturer for Packed Column Absorption - Pin Rotor Machine-SPC – Shipu Machinery

Manufacturer for Packed Column Absorption - Pin Rotor Machine-SPC – Shipu Machinery Detail:

Easy to Maintain

The overall design of SPC pin rotor facilitates easy replacement of wearing parts during repair and maintenance. The sliding parts are made of materials that ensure very long durability.

Higher Shaft Rotation Speed

Compared with other pin rotor machines on the market, our pin rotor machines has a speed of 50~440r/min and can be adjusted by frequency conversion. This ensures that your margarine products can have a wide adjustment range and are suitable for a wider range of oil crystals product

Materials

The product contact parts are made of high-quality stainless steel. The product seals are balanced mechanical seals and food-grade O-rings. The sealing surface is made of hygienic silicon carbide, and the movable parts are made of chromium carbide.

Working Principle

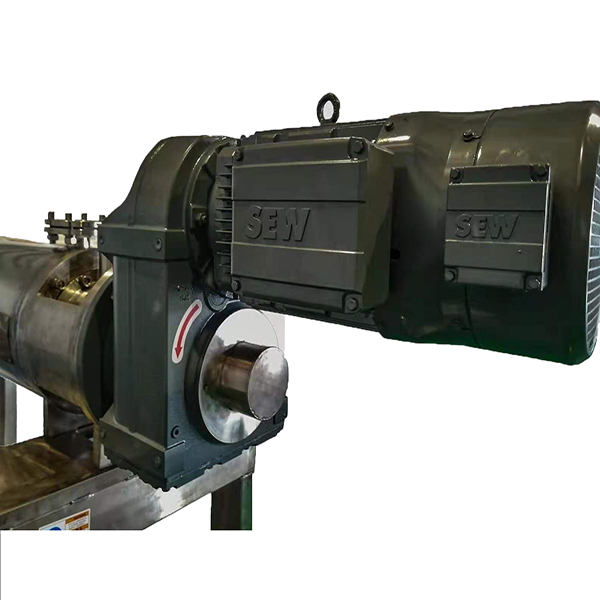

SPC pin rotor adopts a cylindrical pin stirring structure to ensure that the material has sufficient stirring time to break the network structure of the solid fat crystal and refine the crystal grains. The motor is a variable-frequency

speed-regulating motor. The mixing speed can be adjusted according to different solid fat content, which can meet the production requirements of various formulations of margarine manufacturers according to market conditions or consumer groups.

When the semi-finished product of grease containing crystal nuclei enters the kneader, the crystal will grow after a period of time. Before forming the overall network structure, perform mechanical stirring and kneading to break the originally formed network structure, make it recrystallize, reduce the consistency and increase the plasticity.

Working Principle

| 技术参数 | Technical Spec. | Unit | SPC-1000 | SPC-2000 |

| 额定生产能力(人造黄油) | Nominal Capacity(Puff pastry margarine) | kg/h | 1000 | 2000 |

| 额定生产能力(起酥油) | Nominal Capacity(Shortening) | kg/h | 1200 | 2300 |

| 主电机功率 | Main Power | kw | 7.5 | 7.5+7.5 |

| 主轴直径 | Dia. Of Main Shaft | mm | 62 | 62 |

| 搅拌棒间隙 | Pin Gap Space | mm | 6 | 6 |

| 搅拌棒与桶内壁间隙 | Pin-Inner Wall Space | m2 | 5 | 5 |

| 物料筒容积 | Tube Volume | L | 65 | 65+65 |

| 筒体内径/长度 | Inner Dia./Length of Cooling Tube | mm | 260/1250 | 260/1250 |

| 搅拌棒排数 | Rows of Pin | pc | 3 | 3 |

| 搅拌棒主轴转速 | Norminal Pin Rotor Speed | rpm | 440 | 440 |

| 最大工作压力(产品侧) | Max.Working Pressure (material side) | bar | 60 | 60 |

| 最大工作压力(保温水侧) | Max.Working Pressure (hot water side) | bar | 5 | 5 |

| 产品管道接口尺寸 | Processing Pipe Size | DN32 | DN32 | |

| 保温水管接口尺寸 | Water Supply Pipe Size | DN25 | DN25 | |

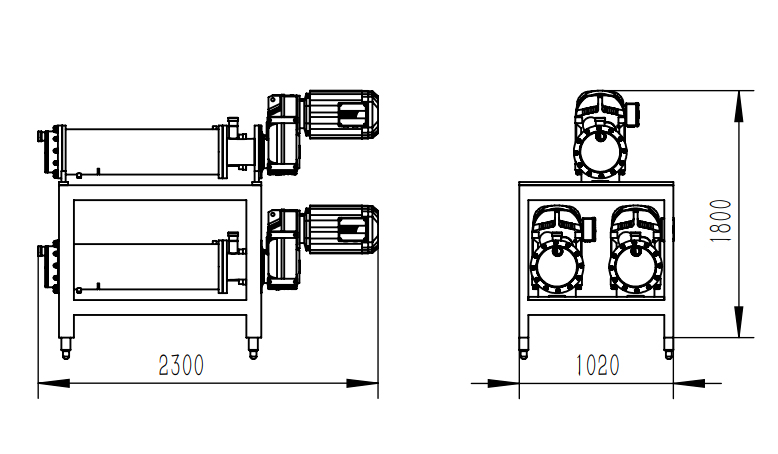

| 机器尺寸 | Overall Dimension | mm | 1800*600*1150 | 1800*1120*1150 |

| 整机重量 | Gross Weight | kg | 600 | 1100 |

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and skilled IT group, we could offer you technical support on pre-sales & after-sales support for Manufacturer for Packed Column Absorption - Pin Rotor Machine-SPC – Shipu Machinery , The product will supply to all over the world, such as: Frankfurt, Munich, Southampton, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.